Biodegradable rare-earth fluorescent film taking polyhydroxybutyrate as matrix as well as preparation method and application of biodegradable rare-earth fluorescent film

A polyhydroxybutyrate, biodegradable technology, used in chemical instruments and methods, luminescent materials, plant protection covers, etc., can solve the problems of poor light energy conversion efficiency, non-degradability, and unsustainability, and achieve thermal stability. Good performance, low cost, and solving unsustainable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

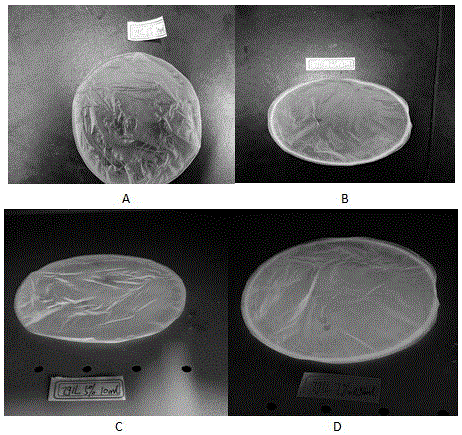

[0033] The following method is used to prepare the biodegradable rare earth fluorescent film with polyhydroxybutyrate as the matrix:

[0034] 1) Accurately weigh 0.0025g Eu(TTA) 2 TPY-OCH 3 Add to the beaker, then measure 3mL of THF into the beaker, stir at room temperature until Eu(TTA) 2 TPY-OCH 3 Completely dissolve, forming Eu(TTA) with a mass fraction of 0.094% 2 TPY-OCH 3 Transparent solution, spare;

[0035] 2) Weigh 0.2496g of PHB into the beaker, then measure 50mL of dichloromethane into the beaker, stir at room temperature until the PHB is completely dissolved and form a PHB solution with a mass fraction of 0.375% for use;

[0036] 3) Pour the above two solutions into the reaction flask and stir at room temperature to obtain a transparent mixed solution;

[0037] 4) Use a dropper to drop the above mixed solution into an evaporating dish, cover the surface with a fresh-keeping film with holes, let the solution evaporate at room temperature for 8 hours, after the solvent is com...

example 2

[0040] The following method is used to prepare the biodegradable rare earth fluorescent film with polyhydroxybutyrate as the matrix:

[0041] 1) Accurately weigh 0.0125g of Eu (TTA) 2 TPY-OCH 3 Add to the beaker, then measure 4mL of THF into the beaker, stir at room temperature until Eu(TTA) 2 TPY-OCH 3 Completely dissolve to form Eu(TTA) with a mass fraction of 0.351% 2 TPY-OCH 3 Transparent solution, spare;

[0042] 2) Weigh 0.2529g of PHB into the beaker, then measure 50mL of dichloromethane and pour into the beaker, stir at room temperature until the PHB is completely dissolved and form a PHB solution with a mass fraction of 0.380%, ready for use;

[0043] 3) Pour the above two solutions into the reaction flask and stir at room temperature to obtain a transparent mixed solution;

[0044] 4) Drop the above mixed solution into an evaporating dish with a dropper, cover the surface with a fresh-keeping film with holes, and let the solution evaporate at room temperature for 18 hours. Af...

example 3

[0047] The following method is used to prepare the biodegradable rare earth fluorescent film with polyhydroxybutyrate as the matrix:

[0048] 1) Accurately weigh 0.0172g of Eu (TTA) 2 TPY-OCH 3 Add to the beaker, then measure 5mL of THF into the beaker, stir at room temperature until Eu(TTA) 2 TPY-OCH 3 Completely dissolved, forming Eu(TTA) with a mass fraction of 0.386% 2 TPY-OCH 3 Transparent solution, spare;

[0049] 2) Weigh 0.2532g of PHB into the beaker, then measure 50mL of dichloromethane and pour into the beaker, stir at room temperature until the PHB is completely dissolved and form a PHB solution with a mass fraction of 0.380%, ready for use;

[0050] 3) Pour the above two solutions into the reaction flask and stir at room temperature to obtain a transparent mixed solution;

[0051] 4) Use a dropper to drop the above mixed solution into an evaporating dish, cover the surface with a fresh-keeping film with holes, and let the solution evaporate at room temperature for 24 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com