Carbonate type saline-alkali land soil conditioner and application thereof to pennisetum sinese planting

A soil improver, carbonate-type technology, applied in the field of soil improvement, can solve the problems of reduced soil bulk density, poor soil pH effect, and ineffective improvement of soil moisture infiltration and air permeability, so as to reduce the bulk density and improve the infiltration rate and increase the total porosity of the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

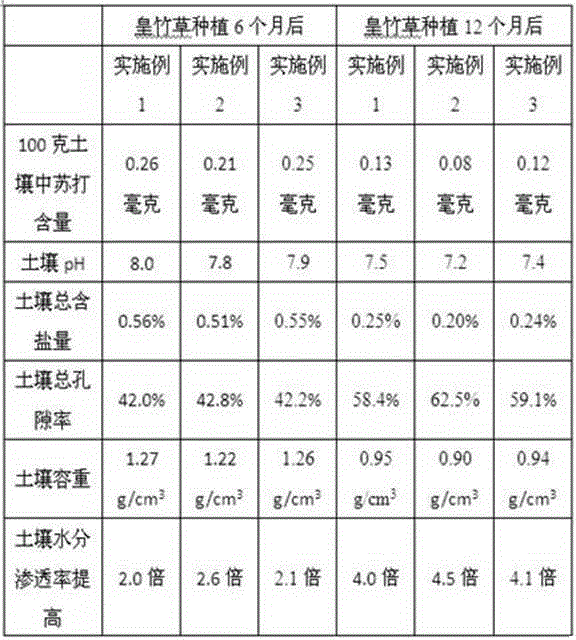

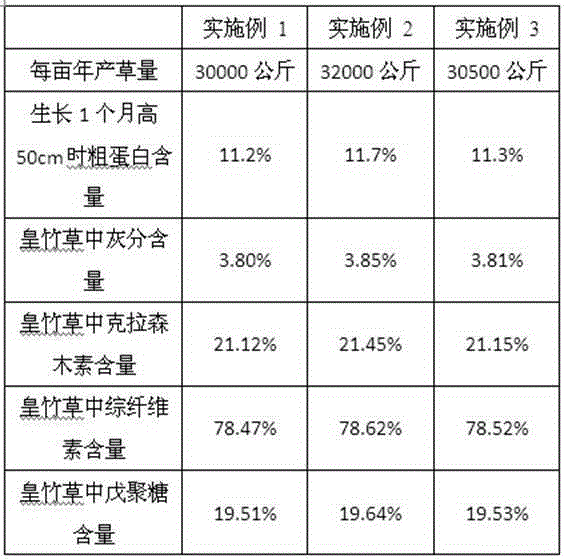

[0029] Embodiment 1 A kind of carbonate type saline-alkali land soil conditioner

[0030] 5 parts of rice husk powder, 6 parts of peat, 12 parts of humic acid-polyacrylic acid, 8 parts of fulvic acid, 4 parts of biochar, 11 parts of cellulose-acrylamide, 20 parts of desulfurized gypsum, 5 parts of dolomite, chitosan 6 parts, 0.001 part of brassinolide, 0.3 part of cod cod, 5 parts of Buddleia powder, 6 parts of Siberian wheatgrass powder, 0.3 part of water retaining agent.

[0031] The water retaining agent includes: 65%-66% of acrylamide, 20%-22% of potassium acrylate, 8%-10% of water, and 0.5%-1.0% of cross-linking agent.

Embodiment 2

[0032] Embodiment 2 A kind of carbonate type saline-alkali land soil conditioner

[0033] 6 parts of rice husk powder, 7 parts of peat, 13 parts of humic acid-polyacrylic acid, 9 parts of fulvic acid, 6 parts of biochar, 12 parts of cellulose-acrylamide, 22 parts of desulfurized gypsum, 6 parts of dolomite, chitosan 7 parts, 0.003 parts of brassinolide, 0.7 parts of cod cod, 6 parts of Buddleia powder, 7 parts of Siberian wheatgrass powder, and 0.5 parts of water retaining agent.

[0034] The water retaining agent includes: 65%-66% of acrylamide, 20%-22% of potassium acrylate, 8%-10% of water, and 0.5%-1.0% of cross-linking agent.

Embodiment 3

[0035] Embodiment 3 A kind of carbonate type saline-alkali land soil conditioner

[0036] 8 parts of rice husk powder, 9 parts of peat, 14 parts of humic acid-polyacrylic acid, 12 parts of fulvic acid, 8 parts of biochar, 14 parts of cellulose-acrylamide, 27 parts of desulfurized gypsum, 8 parts of dolomite, chitosan 9 parts, 0.005 parts of brassinolide, 0.9 parts of cod cod, 8 parts of Buddleia powder, 8 parts of Siberian wheatgrass powder, and 0.7 parts of water retaining agent.

[0037] The water retaining agent includes: 65%-66% of acrylamide, 20%-22% of potassium acrylate, 8%-10% of water, and 0.5%-1.0% of cross-linking agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Salinity | aaaaa | aaaaa |

| Soil bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com