Thermal treatment modification method for PBO (Poly-p-phenylene ben-zobisthiazole) fibers

A heat treatment modification and fiber technology, which is applied in the field of PBO fiber modification and PBO fiber heat treatment modification, can solve the problems of low fiber strength and modulus, unreasonable heat treatment process, etc., and achieve high fiber strength and modulus, Effects of eliminating adverse effects and improving crystallinity and orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

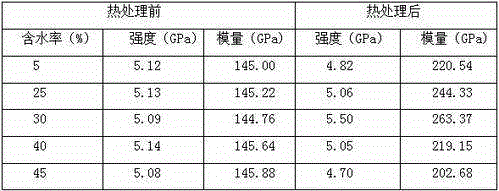

Embodiment 1

[0034] A heat treatment modification method of PBO fiber, comprising the following process steps:

[0035] A. Enter the heat treatment channel

[0036] The PBO fiber obtained by spinning is controlled to have a moisture content of 5%, and then enters a segmented heat treatment channel under an inert atmosphere; the segmented heat treatment channel includes a preheating section, a heat treatment section and a cooling section;

[0037] B. Preheating section

[0038] Put the PBO fiber into the preheating section first, the temperature gradually increases, and the temperature in the preheating section is controlled to be 100-550 °C;

[0039] C, heat treatment section

[0040] After the PBO fiber in the preheating section enters the heat treatment section, the temperature of the heat treatment section is controlled to be 550-630 °C;

[0041] D, cooling section

[0042] The PBO fiber after the heat treatment section finally enters the cooling section, and the temperature gradual...

Embodiment 2

[0044] A heat treatment modification method of PBO fiber, comprising the following process steps:

[0045] A. Enter the heat treatment channel

[0046] The PBO fiber obtained by spinning is controlled to have a moisture content of 45%, and then enters a segmented heat treatment channel under an inert atmosphere; the segmented heat treatment channel includes a preheating section, a heat treatment section and a cooling section;

[0047] B. Preheating section

[0048] Put the PBO fiber into the preheating section first, the temperature gradually increases, and the temperature in the preheating section is controlled to be 100-550 °C;

[0049] C, heat treatment section

[0050] After the PBO fiber in the preheating section enters the heat treatment section, the temperature of the heat treatment section is controlled to be 550-630 °C;

[0051] D, cooling section

[0052] The PBO fiber after the heat treatment section finally enters the cooling section, and the temperature gradua...

Embodiment 3

[0054] A heat treatment modification method of PBO fiber, comprising the following process steps:

[0055] A. Enter the heat treatment channel

[0056] The PBO fiber obtained by spinning is controlled to have a moisture content of 25%, and then enters a segmented heat treatment channel under an inert atmosphere; the segmented heat treatment channel includes a preheating section, a heat treatment section and a cooling section;

[0057] B. Preheating section

[0058] Put the PBO fiber into the preheating section first, the temperature gradually increases, and the temperature in the preheating section is controlled to be 100-550 °C;

[0059] C, heat treatment section

[0060] After the PBO fiber in the preheating section enters the heat treatment section, the temperature of the heat treatment section is controlled to be 550-630 °C;

[0061] D, cooling section

[0062] The PBO fiber after the heat treatment section finally enters the cooling section, and the temperature gradua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com