Dendritic nanowire catalyst carrier with metal oxide/carbon core-sheath structure and preparation method of supported catalyst

A catalyst carrier, metal nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of poor stability, high cost, poor catalyst performance, etc., to improve stability, The effect of solving poor conductivity and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

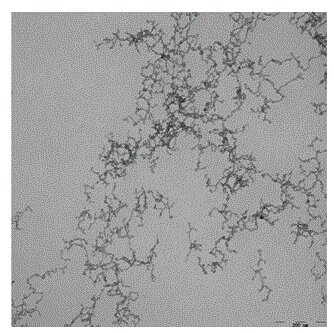

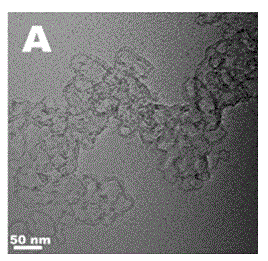

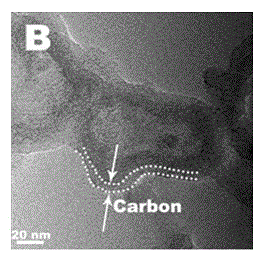

[0028] Specific embodiment 1: The metal oxide / carbon dendritic nanowire with a core-sheath structure provided in this embodiment is a dendritic nanowire catalyst carrier with a metal oxide / carbon core-sheath structure with a uniform diameter, and the nanowire The diameter is 3-200nm, and the thickness of the carbon sheath is 0.5-20nm.

[0029] The dendritic nanowire catalyst carrier of the metal oxide / carbon core sheath structure described in this embodiment has a unique nanowire structure, and this special shape has a relatively high active area, and the diameter of the nanowire and the thickness of the carbon sheath can be effectively adjusted. regulation, its TEM image is shown in Figure 2-3 shown.

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the metal oxide can be an oxide or a metal-doped oxide, and the doped metal is Pt, Pd, Ru, Os , Rh, Ir, Ag, Au, Re, Cr, Fe, Mn, Co, Ni, Cu, Zn, In, Sn and Sb or one or more of them, the doping ratio is 0.1~40wt.%; metal Oxide is Al 2 o 3 , Ga 2 o 3 , SiO 2 、GeO 2 、TiO 2 , ZrO 2 , V 2 o 5 、Cr 2 o 3 , MnO 2 , Fe 2 o 3 , Fe 3 o 4 、Co 2 o 3 , NiO, CuO, ZnO, Nb 2 o 5 、MoO 3 , RuO 2 、In 2 o 3 , SnO 2 , Sb 2 o 3 , Sb 2 o 5 , Tl 2 o 3 , PbO, Bi 2 o 3 , La 2 o 3 、 Ta 2 o 5 、WO 2 、WO 3 、 Bi 2 o 3 and CeO 2 One of.

specific Embodiment approach 3

[0031] Specific embodiment three: This embodiment provides a method for preparing a dendritic nanowire catalyst carrier with a metal oxide / carbon core sheath structure, which is specifically completed in the following steps:

[0032]1. Prepare a uniform and transparent reactant solution: stir the oxide precursor (or the mixed solution of the oxide precursor and the metal dopant precursor) and the acid solution at a stirring speed of 100~1000rpm for 10~120min and disperse in the multi-component In the alcohol, the molar ratio of the metal dopant precursor and the oxide precursor in the mixed solution is controlled to be 0.001-0.3, the concentration of the metal precursor is 10-100mmoL / L, and the acid concentration is 0.01-1moL / L.

[0033] 2. Solvothermal reaction: put the mixed solution in a high-pressure reactor for reaction, control the reaction temperature at 120~300°C, and the reaction time is 0.5~15h. After the reaction is completed, it is naturally cooled to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com