High lithium ion conductivity lithium sulphur battery capable of restraining shuttle of polysulfide ions

A lithium-sulfur battery, ion conduction technology, applied in non-diaphragm lithium-sulfur batteries, modification of lithium-ion conductive polymer materials, binders, and sulfur electrodes, can solve the problem of unable to prevent polysulfide ion shuttle, lithium-sulfur battery capacity Recession, sulfur electrode capacity decline and other problems, to achieve the effect of lithium ion conduction and inhibition of polysulfide ion shuttle strengthening, inhibition of capacity decline, speed capacity and performance stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

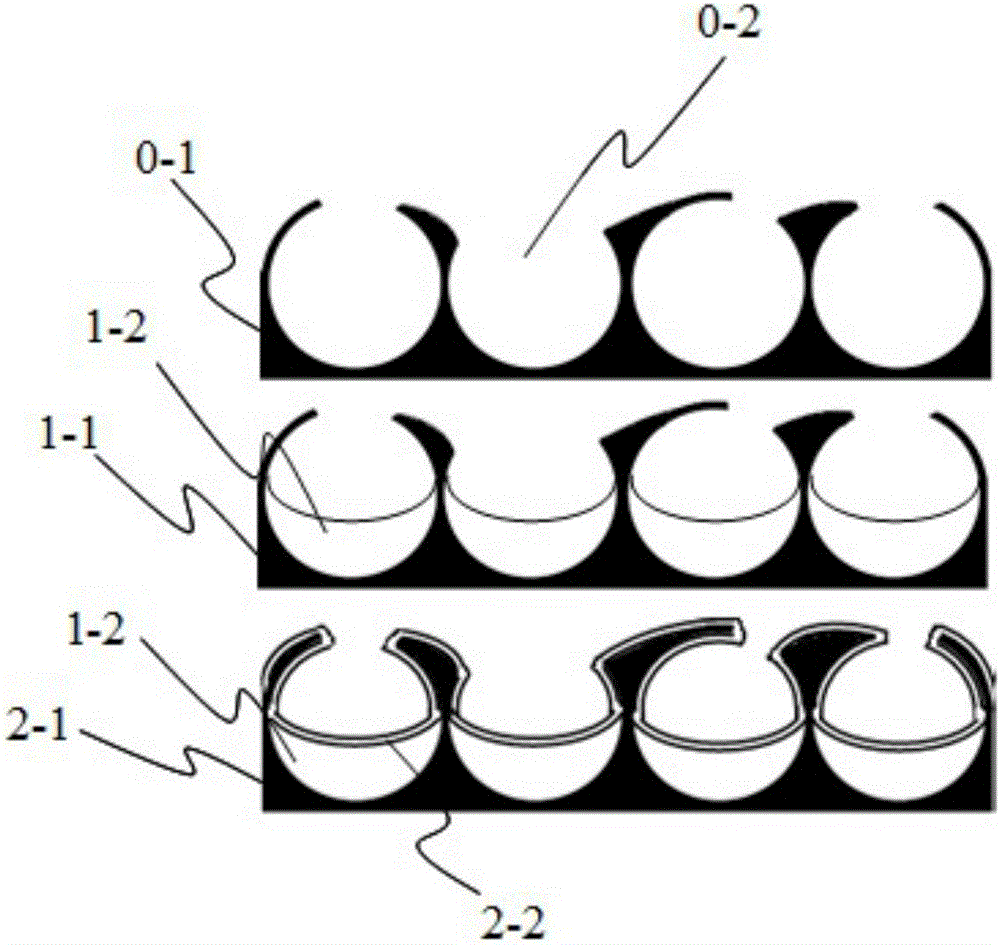

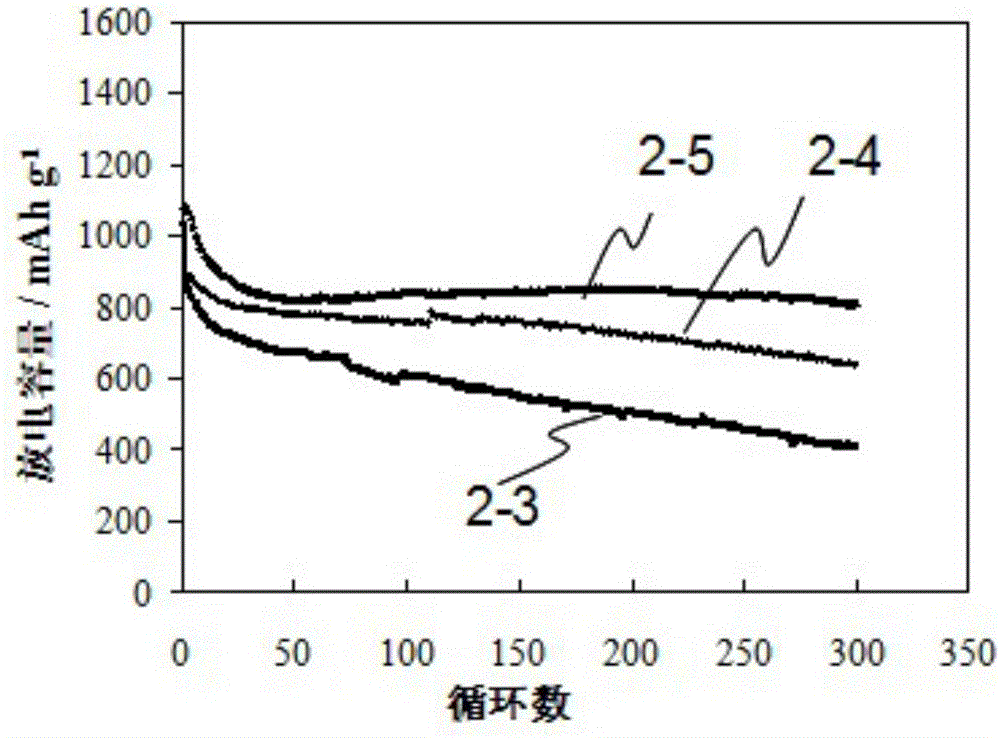

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of macroporous carbon material

[0041] According to the mass ratio of 1:1, weigh the hydrophilic nano-CaCO produced by Ruicheng Warner Nano Materials Co., Ltd., with a particle size of 15-40nm. 3 Add 10g of glucose and 10g each to 100ml deionized water, mix with ultrasonic vibration for 30 minutes to dissolve glucose and mix with nano-CaCO 3 Disperse evenly; heat to evaporate the water, heat to evaporate the water, and then cure at 160°C for 2 hours; heat the cured product to 700°C under the protection of a nitrogen atmosphere, and carbonize at a constant temperature for 2 hours; then carbonize at a constant temperature of 900°C for 2 hours; carbonize The product was washed successively with 5 wt% nitric acid and deionized water, and then vacuum-dried at 120° C. for 4 hours to obtain a macroporous carbon material.

Embodiment 2

[0042] Example 2: Preparation of cathode material

[0043] The elemental sulfur and the macroporous carbon obtained in Example 1 were mechanically mixed at a mass ratio of 7:3, placed in a reactor made of 316 stainless steel, and then the reactor was vacuumed and heated to 80°C. After 5 hours of reaction, After the sulfur loading is completed, the reaction product is cooled to 25° C. to obtain the positive electrode material.

Embodiment 3

[0044] Embodiment three: Li + - Preparation of Nafion resin

[0045] Get 20gLiOH and join in 100mlNafion (20wt%, produced in DuPont Company), after stirring for 30 minutes, centrifuge off excess LiOH, obtain Li + - Nafion solution. Li was obtained after vacuum drying + -Nafion resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com