Fentrazamide-containing weeding microemulsion

A technology of tetramide and microemulsion, which is applied in the field of pesticides, can solve the problems affecting the environmental safety of herbicide persistence, phytotoxicity of recommended crops, and poor weeding effect, so as to achieve good drug degradation effect and low residual Less, the effect of improving the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

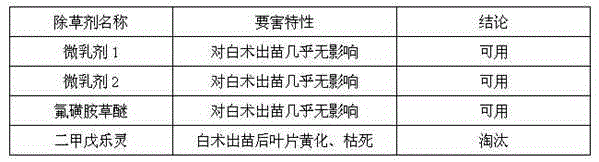

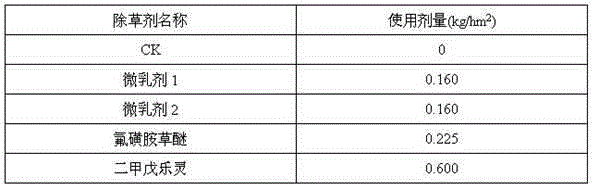

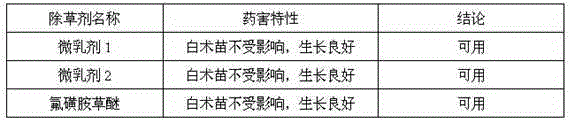

Method used

Image

Examples

preparation example Construction

[0023] Surfactant provided by the invention is octylphenol polyoxyethylene ether sulfonate, and its preparation method comprises:

[0024] The first step, the chlorination of octylphenol polyoxyethylene ether;

[0025] The second step is the sulfonation of octylphenol polyoxyethylene ether after chlorination.

[0026] The first step is further specifically adding octylphenol polyoxyethylene ether (OP-4) and pyridine into the reaction vessel at a molar ratio of 1:1, adding thionyl chloride dropwise under constant temperature water bath conditions, chlorine The molar ratio of sulfoxide to octylphenol polyoxyethylene ether was 1.5:1, stirred and reacted at 70°C to 80°C for 2 hours, and chlorooctylphenol polyoxyethylene ether was synthesized.

[0027] The second step is further specifically adding chlorooctylphenol polyoxyethylene ether to water, the mass ratio of chlorooctylphenol polyoxyethylene ether to water is 1:1.5, and then adding sulfonating agent sodium sulfite (Na 2 SO...

Embodiment 1

[0030] Embodiment 1 octylphenol polyoxyethylene ether sulfonate

[0031] Mix 10 mol of octylphenol polyoxyethylene ether (OP-4) and 10 mol of pyridine into the reaction vessel, add 15 mol of thionyl chloride dropwise in a constant temperature water bath, stir and react at 80°C for 2 hours, and synthesize chlorooctyl Base phenol polyoxyethylene ether, get the obtained 7.5mol chlorooctylphenol polyoxyethylene ether and join in water, the mass ratio of chlorooctylphenol polyoxyethylene ether and water is 1:1.5, then add 5mol sulfonating agent Sodium sulfite (Na 2 SO 3 ), placed in a high-pressure reactor, and reacted at 150°C for 8 hours under vigorous stirring to obtain a light yellow viscous substance. The crude product was dissolved in a mixture of isopropanol and water with a volume ratio of 2:1, and then extracted with petroleum ether , to remove unreacted raw materials and other oil-soluble impurities, separate the lower layer, distill under reduced pressure, and dry in v...

Embodiment 2

[0032] Embodiment 2 Microemulsion 1

[0033] Surfactant 15g prepared by rimsulfuron-methyl 60g, quinazole 30g and 12g tetramazole, embodiment 1, emulsifier 250g sodium dioctyl succinate sulfonate, cosolvent ethanol 150g, Put 40 g of antifreeze glycerol and 30 g of synergist butyristerin into the reaction kettle, stir evenly and completely dissolve, slowly add 800 g of water, continue mixing and stirring for 2 hours, and obtain a microemulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com