Milk powder capable of improving intelligence and immunity of infants and dry-mixing production technology thereof

A production process and resistance technology, applied in the field of milk powder and its dry mixing production process, can solve the problems of incomplete nutrition, unreasonable process methods, loss of activity, etc., to ensure nutrition and functionality, avoid prolonged contact, Promotes well-mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

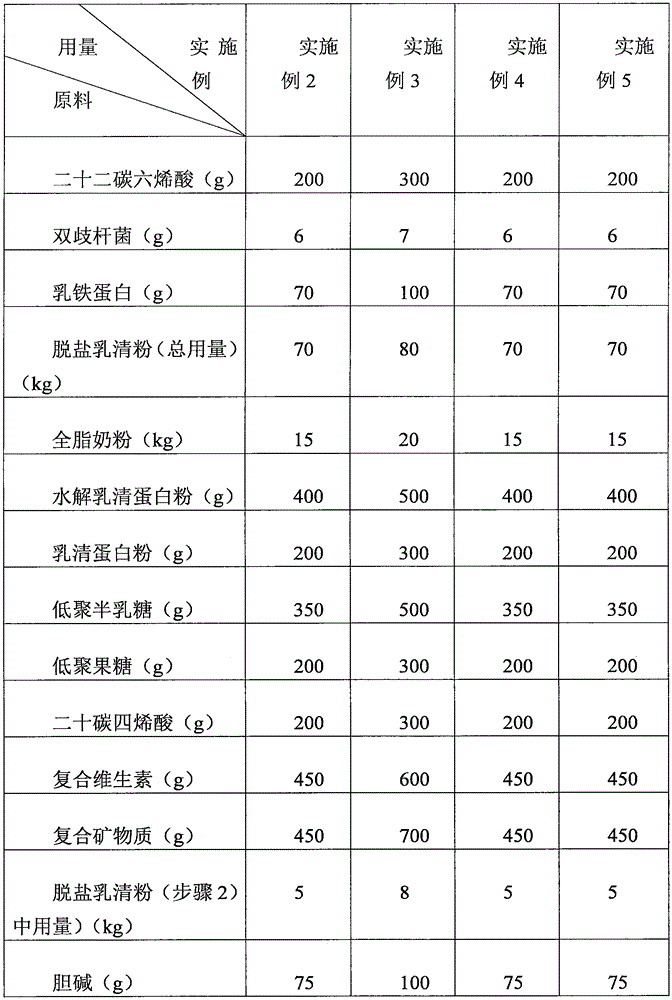

Examples

Embodiment 1

[0023] Embodiment 1: A kind of milk powder that improves infant intelligence and resistance

[0024] The milk powder for improving the intelligence and resistance of infants and young children in this embodiment is prepared from the following raw materials in parts by weight: choline 50g, docosahexaenoic acid 100g, active probiotic combination 5g, lactoferrin 40g, desalted whey Powder 60kg, whole milk powder 10kg, hydrolyzed whey protein powder 300g, whey protein powder 100g, galacto-oligosaccharides 200g, fructo-oligosaccharides 100g, eicosadonic acid 100g, multivitamins 300g, multiminerals 200g. The active probiotic combination of this embodiment is preferably bifidobacteria.

[0025] The dry-mixed production process of the milk powder that improves the intelligence and resistance of infants and young children of the present embodiment specifically includes the following steps:

[0026] 1) Prefabricated material: mixing the raw materials contained in the multivitamins and t...

Embodiment 3

[0030] After step 3) in embodiment 3, step 4) and packaging are also included: the milk powder obtained in step 3) for improving the intelligence and resistance of infants is evacuated and filled with inert gas, and then packaged.

Embodiment 4

[0031] In the step 2 of embodiment 4), use the three-dimensional mixer to carry out one-level premixing, and the mixing time of the first-level premixing is 10min, and the rotating speed of the three-dimensional mixer is 10 revolutions / min during the mixing of the first-level premixing; Step 3) uses a high-speed mixer Carry out secondary dry mixing, the mixing time of secondary dry mixing is 100s, and the speed of high-speed mixer is 35 rpm during secondary dry mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com