Sn-Zn-series lead-free brazing filler metal and preparation method thereof

A lead-free solder, sn-zn technology, used in manufacturing tools, welding equipment, metal processing equipment, etc., to achieve the effect of high joint strength, reduced oxide, excellent oxidation resistance and wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

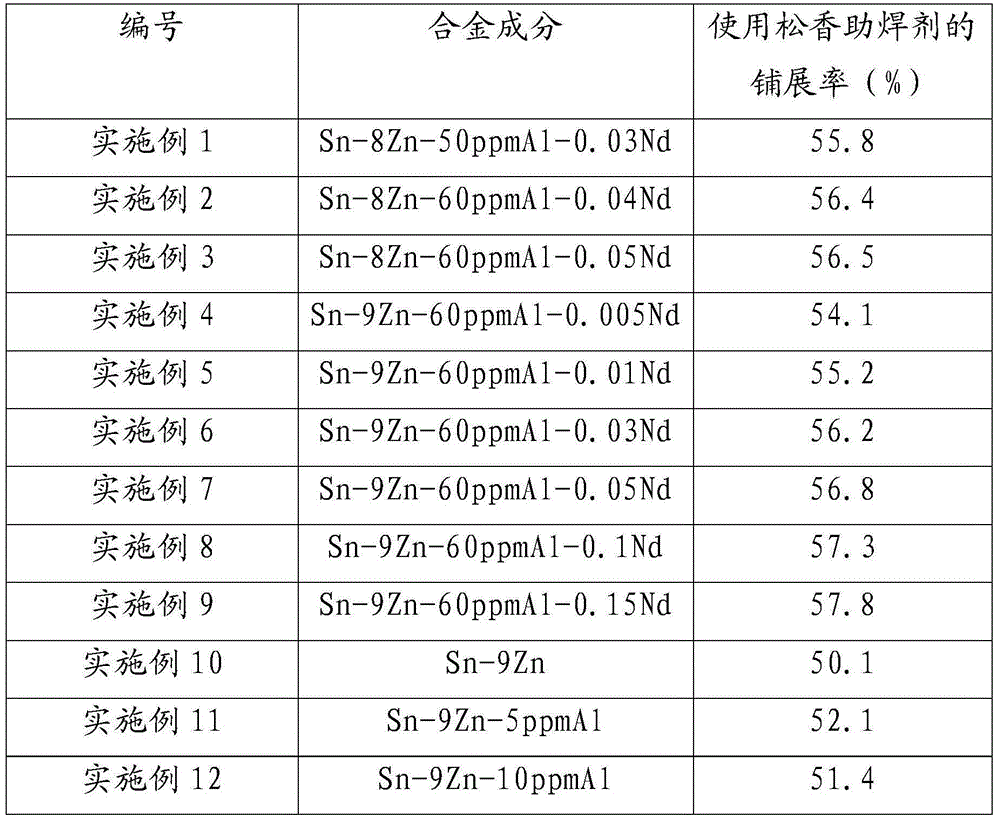

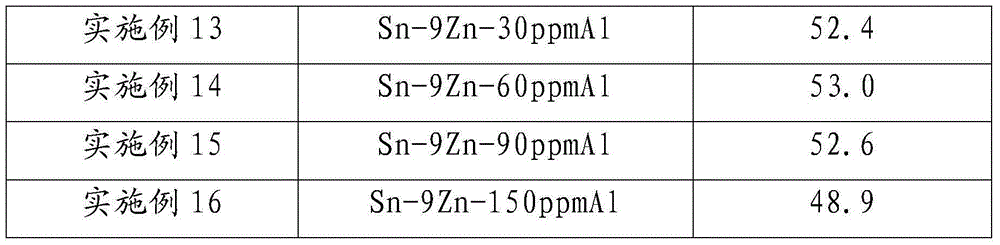

Examples

Embodiment 1

[0026] Take the preparation of 1000 solder as an example

[0027] Described Sn-Zn series lead-free solder, each component is respectively by weight percent:

[0028] Zn: 8%; Al: 0.005%; Nd: 0.03%; Sn: balance.

[0029] The preparation method of described Sn-Zn series lead-free solder, comprises the steps:

[0030] Step S1: Preparation of Master Alloy

[0031] Step S11: According to the weight percentage, Al is 10%, Sn is the balance, and a Sn-10Al master alloy is prepared, and the specific preparation method is as follows:

[0032] Step S111: heating the Sn and Al to 700°C, and passing in an inert gas for protection;

[0033] Step S112: After the Al is completely dissolved into the Sn, stop heating and cool down to lower the temperature to 380° C. At this time, perform stirring and slag removal to obtain the Sn-10Al master alloy melt;

[0034] Step S113: casting the Sn-10Al master alloy melt into a plate-shaped ingot to obtain the Sn-10Al master alloy.

[0035] Step S12: ...

Embodiment 2

[0046] Take the preparation of 1000 solder as an example

[0047] Described Sn-Zn series lead-free solder, each component is respectively by weight percent:

[0048] Zn: 8%; Al: 0.006%; Nd: 0.04%; Sn: balance.

[0049] The preparation method of described Sn-Zn series lead-free solder, comprises the steps:

[0050] Step S1: Preparation of Master Alloy

[0051] Step S11: According to the weight percentage, Al is 10%, Sn is the balance, and a Sn-10Al master alloy is prepared, and the specific preparation method is as follows:

[0052] Step S111: heating the Sn and Al to 750°C, and passing in an inert gas for protection;

[0053] Step S112: After the Al is completely dissolved into the Sn, stop heating and cool down to lower the temperature to 400° C. At this time, perform stirring and slag removal to obtain the Sn-10Al master alloy melt;

[0054] Step S113: pouring the Sn-10Al master alloy melt into a U-shaped channel steel to form a 5 mm thick plate-shaped ingot to obtain the ...

Embodiment 3

[0066] Take the preparation of 1000 solder as an example

[0067] Described Sn-Zn series lead-free solder, each component is respectively by weight percent:

[0068] Zn: 8%; Al: 0.006%; Nd: 0.05%; Sn: balance.

[0069] The preparation method of described Sn-Zn series lead-free solder, comprises the steps:

[0070] Step S1: Preparation of Master Alloy

[0071] Step S11: According to the weight percentage, Al is 10%, Sn is the balance, and a Sn-10Al master alloy is prepared, and the specific preparation method is as follows:

[0072] Step S111: heating the Sn and Al to 800°C, and passing in an inert gas for protection;

[0073] Step S112: After the Al is completely dissolved into the Sn, stop heating and cool down to lower the temperature to 420° C., then stir and remove slag to obtain the Sn-10Al master alloy melt;

[0074] Step S113: pouring the Sn-10Al master alloy melt into the U-shaped channel steel to form a 7 mm thick plate-shaped ingot to obtain the Sn-10Al master al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com