A special fixture for thermocouple verification and thermocouple verification method

A special fixture and thermocouple technology, applied in the direction of measuring heat, manufacturing tools, workpiece clamping devices, etc., can solve the problems that the alligator clip cannot meet the parasitic potential, increase the error component of the verification result, and the error of the large measurement result, etc., to shorten the verification The effect of operating the process, improving measurement accuracy, and avoiding verification errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Exemplary embodiments will be described in detail herein, and examples thereof are shown in the accompanying drawings. When the following description refers to the accompanying drawings, unless otherwise indicated, the same numerals in different drawings represent the same or similar elements, and the following exemplary The embodiments described in the examples do not represent all embodiments consistent with the present invention.

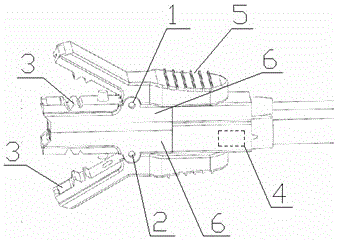

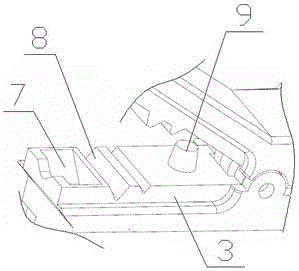

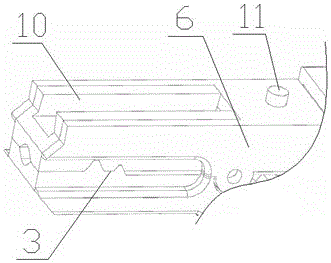

[0029] A special fixture for thermocouple verification, which includes a clamp body A1 and a clamp body B2 connected together, the clamp body A1 is used to connect the positive pole of the thermocouple, and the clamp body B2 is used to connect the negative pole of the thermocouple, and the clamp bodies A1 and B2 are both set There is a spring clip structure. The front end of the spring clip structure is the clip 3. The inner cores of the clip body A1 and B2 and the clip mouth of the clip body are all made of metal with good thermal conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com