Device and method for achieving laser rapid molding of superhigh molecular weight polymer

A laser rapid prototyping and ultra-high molecular weight technology, which is applied in the field of laser rapid prototyping devices, can solve the problem of affecting the quality of molding, affecting the stiffness of products, tensile strength hardness, heat resistance, solvent resistance, air tightness and chemical corrosion resistance , laser energy density, temperature sensitivity of sintering position, etc., to achieve high-quality molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

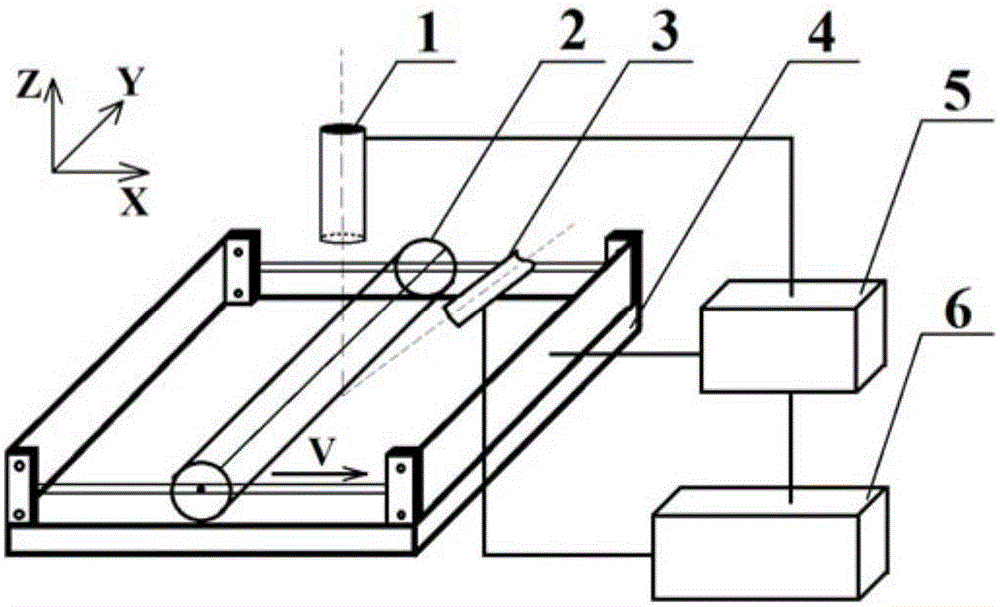

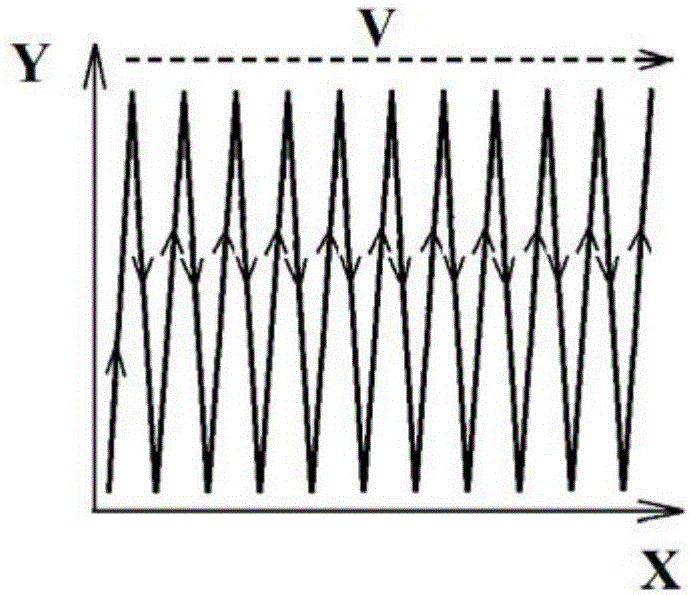

[0055] Laser rapid prototyping of ultra-high molecular weight polyethylene (UHMWPE) with a molecular weight of 4.5 million was performed using a 1064nm Nd:YAG all-solid-state laser. Among them, the output laser power of the laser emitting end is 10W, and the spot diameter is 0.8mm; the scanning speed of the laser emitting end is 0.8mm / s, and the horizontal moving speed of the pressure roller is 0.1mm / s. During the forming process, the temperature of the sintering position is controlled within the range of 210-240°C. Finally, a good molded part without pores is obtained.

Embodiment 2

[0057] Use 10.6um CO 2 A CW laser performs laser rapid prototyping of ultra-high molecular weight nylon (UHMWPA) with a molecular weight of 2 million. Among them, the output laser power of the laser emitting end is 35W, and the spot diameter is 1mm; the scanning speed of the laser emitting end is 0.6mm / s, and the horizontal moving speed of the pressure roller is 0.1mm / s. During the forming process, the temperature of the sintering position is controlled within the range of 200-230°C. Finally, a good molded part without pores is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com