Catalyst-free industrial continuous production method of diethanolisopropanolamine

A technology of monoisopropanolamine and production method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem that the stability of diethanol monoisopropanolamine is difficult to control and guarantee, and the labor intensity of operators It is beneficial to the promotion and application of industrialization, the labor intensity of workers is low, and the material consumption and energy consumption are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

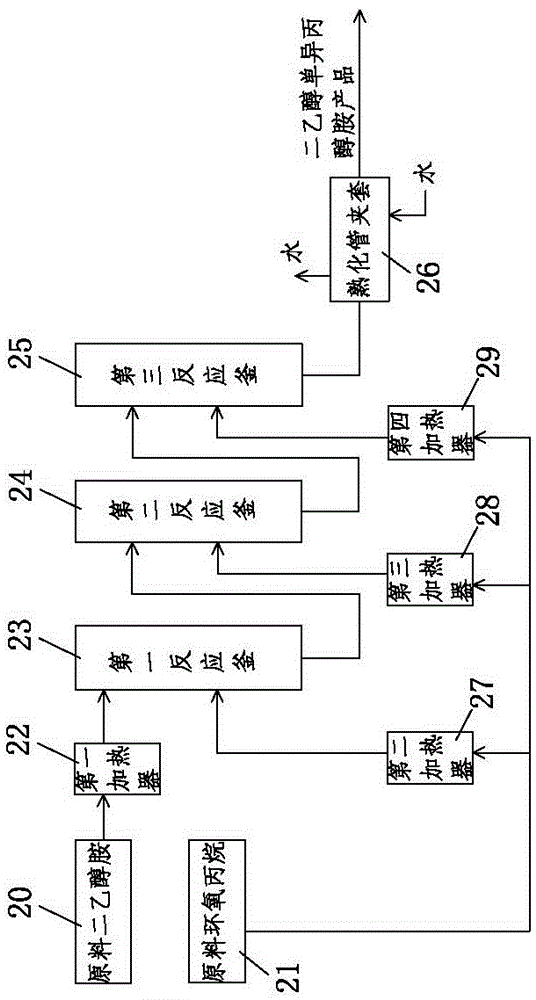

[0041] See figure 2 . A kind of industrial continuous production method of the catalyst-free production of diethanol monoisopropanolamine of the present embodiment, it comprises the following steps:

[0042] (1) Input the raw material diethanolamine 20 into the first heater 22 and heat it to 130°C, then enter the first reaction kettle 23, and at the same time, input a part of the raw material propylene oxide 21 into the second heater 27, heat it to 85°C, and then enter the first reaction Kettle 23: control the pressure and temperature of the first reaction kettle 23, after the raw material diethanolamine 20 and a part of the raw material propylene oxide 21 react in the first reaction kettle 23 for 150min, the first mixture containing diethanol monoisopropanolamine is generated , the content of diethanol monoisopropanolamine in the first mixture is 88%; in this embodiment, the pressure of the first reactor 23 is 0.15Mpa, and the temperature of the first reactor 23 is 142°C. ...

Embodiment 2

[0052] See figure 2 . A kind of industrial continuous production method of the catalyst-free production of diethanol monoisopropanolamine of the present embodiment, it comprises the following steps:

[0053] (1) Input the raw material diethanolamine 20 into the first heater 22 and heat it to 120°C, then enter the first reaction kettle 23, and at the same time, input a part of the raw material propylene oxide 21 into the second heater 27, heat it to 70°C, and then enter the first reaction Kettle 23: control the pressure and temperature of the first reaction kettle 23, after the raw material diethanolamine 20 and a part of the raw material propylene oxide 21 react in the first reaction kettle 23 for 100min, the first mixture containing diethanol monoisopropanolamine is generated , the content of diethanol monoisopropanolamine in the first mixture is 90%; in this embodiment, the pressure of the first reactor 23 is 0.05Mpa, and the temperature of the first reactor 23 is 155°C. ...

Embodiment 3

[0063] See figure 2 . A kind of industrial continuous production method of the catalyst-free production of diethanol monoisopropanolamine of the present embodiment, it comprises the following steps:

[0064] (1) Input the raw material diethanolamine 20 into the first heater 22 to heat to 150°C and then enter the first reaction kettle 23, and at the same time, input a part of the raw material propylene oxide 21 into the second heater 27 to heat to 100°C and then enter the first reaction Kettle 23: control the pressure and temperature of the first reaction kettle 23, after the raw material diethanolamine 20 and a part of the raw material propylene oxide 21 react in the first reactor 23 for 180min, the first mixture containing diethanol monoisopropanolamine is generated , the content of diethanol monoisopropanolamine in the first mixture is 89%; in this embodiment, the pressure of the first reactor 23 is 0.20Mpa, and the temperature of the first reactor 23 is 130°C.

[0065] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com