Refining method of high-purity epalrestat

A technology of epalrestat and refining method, which is applied in the direction of organic chemistry, can solve the problems of difficult operation, low purity and yield of the final product, etc., and achieve the effect of single solvent, convenient operation and small amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

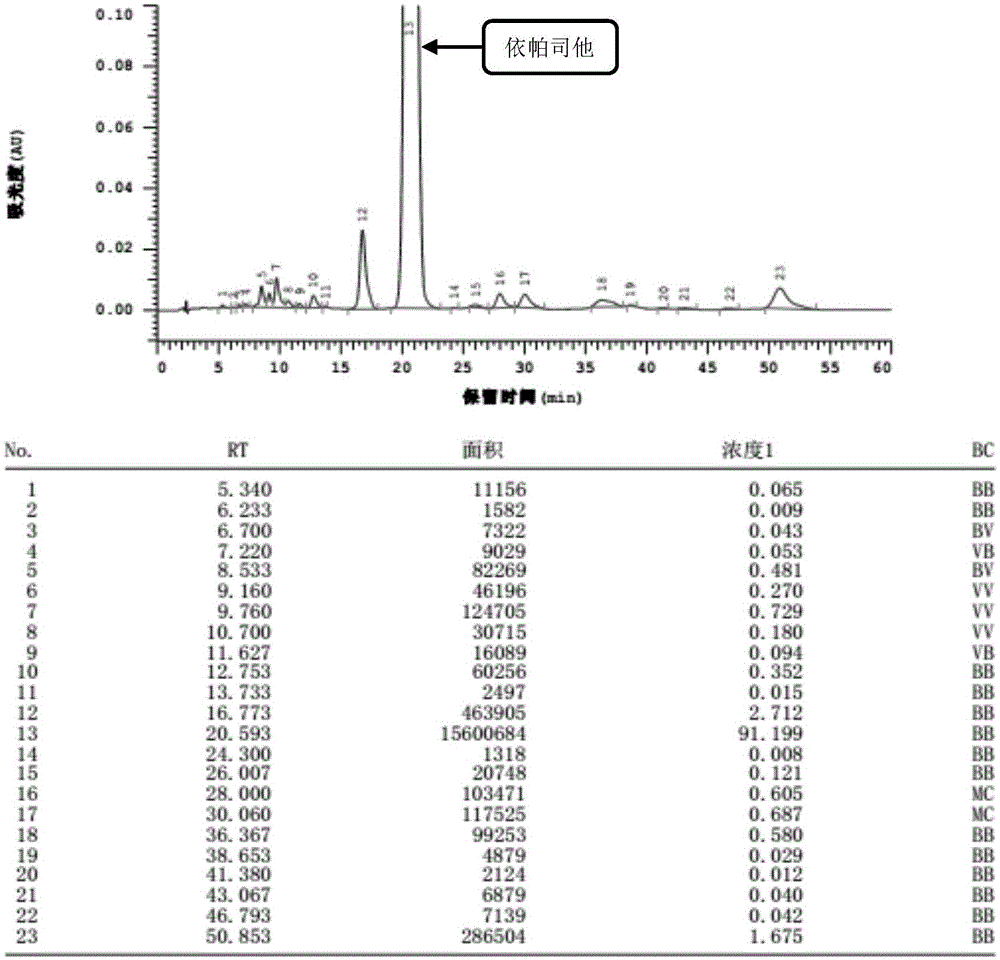

Image

Examples

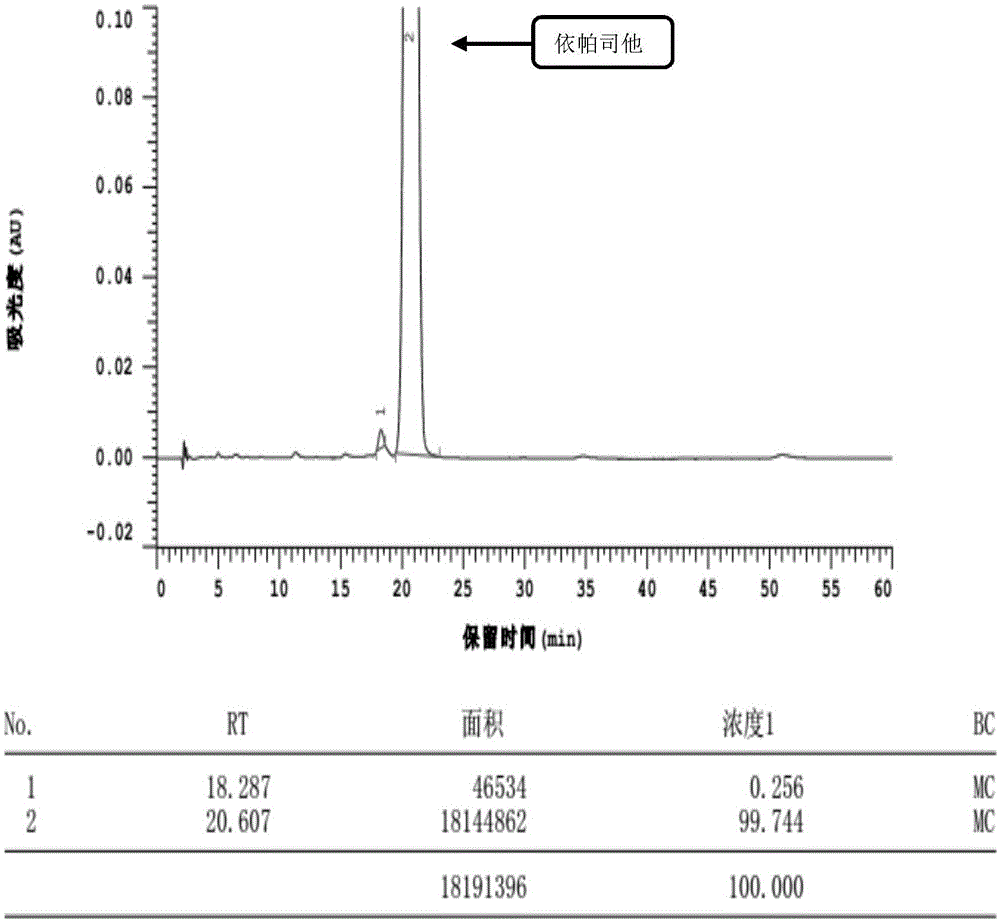

Embodiment 1

[0027] Add 500g of epalrestat and 750ml of 1,4-dioxane into a 5000ml three-necked bottle, and stir under reflux in the dark at 110°C to dissolve. Stand at ~40°C for 3-5h, suction filter at 30-35°C, wash the filter cake once with a small amount of 80% aqueous methanol solution, dry at 60°C, and weigh to obtain 416.5g of epalrestat with a purity of 99.744%. Yield 86.3%.

[0028] Three consecutive batches of small test experimental data:

[0029] batch number

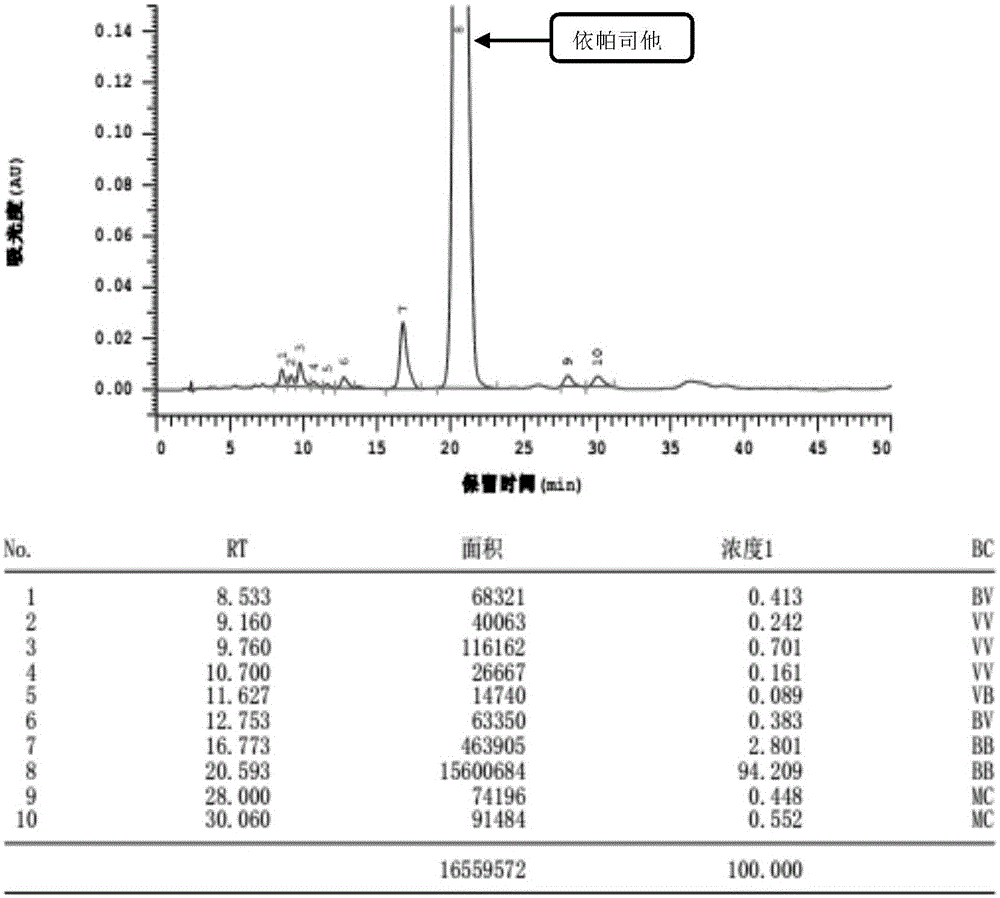

Embodiment 2

[0031] Add 500g of epalrestat and 845ml of tetrahydrofuran into a 5000ml three-necked bottle, and stir under reflux at 110°C in the dark to dissolve, then continue to add 2600ml of 80% methanol aqueous solution to it after dissolving, stir for 5 minutes, and then stand at 35-40°C Suction filtration at 30-35°C for 3-5 hours, the filter cake was washed once with a small amount of 80% aqueous methanol solution, dried at 60°C, and weighed to obtain 406.7g of epalrestat with a purity of 99.517% and a yield of 81.3%.

Embodiment 3

[0033] Add 500g of epalrestat and 550ml of dimethylformamide into a 5000ml three-necked bottle, and stir under reflux at 110°C in the dark to dissolve, then continue to add 3300ml of ethanol to it after dissolving, stir for 5min, and then stand at 35-40°C Leave it for 3-5 hours, suction filter at 30-35°C, wash the filter cake once with a small amount of ethanol, dry at 60°C, and weigh to obtain 392.0 g of epalrestat with a purity of 99.601% and a yield of 78.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com