A high thermal conductivity aromatic polyoxadiazole precipitation fiber mica insulation material and its preparation method and application

A technology of polyoxadiazole and precipitating fiber, which is applied in the fields of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, textile and papermaking, etc. Good properties, physical properties, and product processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

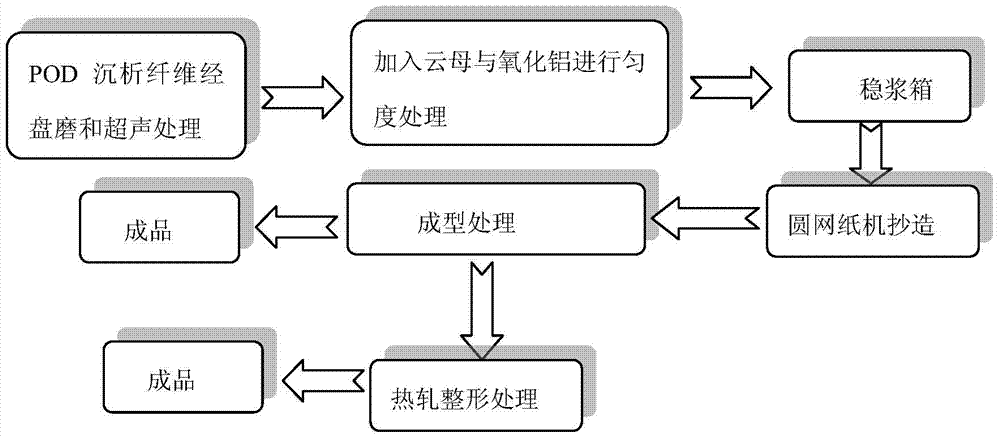

Method used

Image

Examples

Embodiment 1

[0029] Prepare high thermal conductivity fiber mica insulation material according to the following ratio:

[0030] POD precipitated fiber 5 parts by weight

[0031] Muscovite 70 parts by weight

[0032] Aluminum oxide 25 parts by weight

[0033] First, the surface of the POD precipitated fiber with the above content is treated by disc grinding and ultrasonic to make the degree of beating 55-75°SR, and then put into the slurry mixing tank together with the above content of mica and alumina, and then hydraulically The mixer is fully stirred for 8 to 20 minutes until the raw materials are evenly dispersed. Then the uniformly dispersed pulp flows into the stock stabilization box, and the online valve of the stock stabilization box is adjusted to make the stock evenly distributed on the forming net of the rotary paper machine. When the slurry runs along the forming wire, the excess water is filtered out from the slurry by using the pressure of the couch roll, and the paper embry...

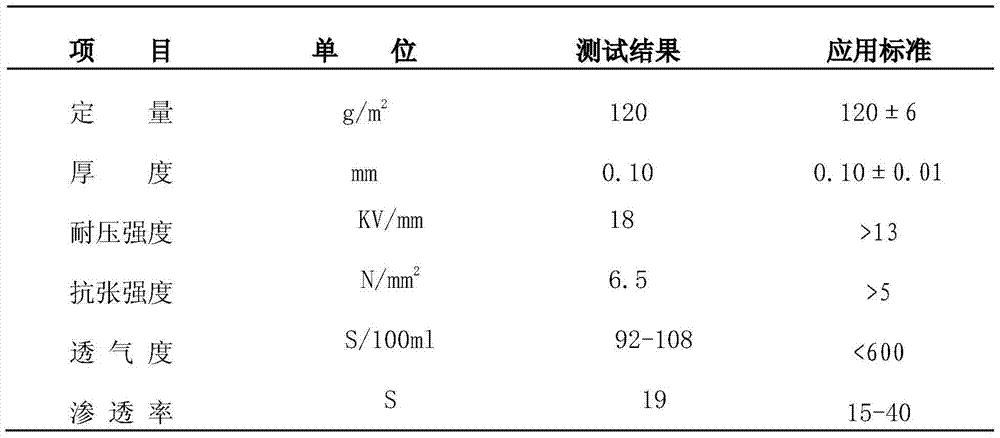

Embodiment 2

[0037] Prepare high thermal conductivity fiber mica insulation material according to the following ratio:

[0038] POD precipitated fiber 5 parts by weight

[0039] Calcined mica 70 parts by weight

[0040] Aluminum oxide 25 parts by weight

[0041] The preparation method is the same as that of Example 1, the performance index is shown in Table 2, and the test results of thermal conductivity are shown in Table 5.

[0042] Table 2 Product Measured Indicators

[0043]

Embodiment 3

[0045] Prepare high thermal conductivity fiber mica insulation material according to the following ratio:

[0046] POD fibrid 7 parts by weight

[0047] Muscovite 83 parts by weight

[0048] Aluminum oxide 10 parts by weight

[0049] The preparation method is the same as that of Example 1, the performance index is shown in Table 3, and the test results of thermal conductivity are shown in Table 5.

[0050] Table 3 Product Measured Indicators

[0051]

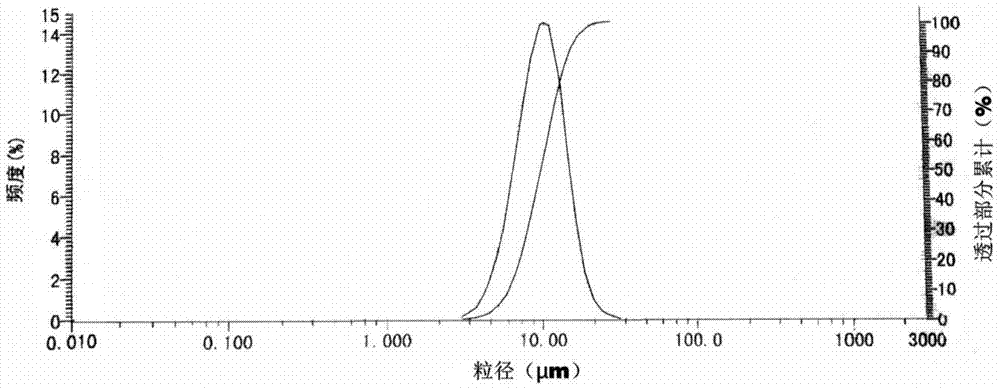

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com