Glass for liquid crystal display and manufacture method thereof

A liquid crystal display and glass technology, applied in the field of glass manufacturing, can solve problems such as products that have not yet appeared, and achieve the effects of high elastic modulus, low glass density, and easy melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a kind of substrate glass that liquid crystal display is used, and this glass is prepared by weight percentage (wt%) with following each raw material: 58-64SiO 2 , 8-15B 2 o 3 , 12-16Al 2 o 3 , 5-9MgO, 6-8CaO, 2-4BaO, 1-4Y 2 o 3 , 0.005-0.1R 2 O (R=Li, Na or K), and 0-2SnO 2 and\or 0-0.5CeO 2 and\or 0-1Cl. Among them, 0-2SnO 2 , 0-0.5CeO 2 , 0-1Cl is the clarifying agent, at least one of the three can be selected according to needs.

[0024] The glass prepared with the above ingredients and percentages has a density less than 2.38g / cm 3 , the average linear expansion coefficient in the range of 20-300°C is greater than 31×10-7 / °C, less than 39×10-7 / °C, preferably less than 38×10-7 / °C; the strain point is greater than 650°C, preferably not less than 660 ℃; elastic modulus greater than 7.3kg / mm 2 , preferably greater than 7.4kg / mm 2 , more preferably greater than 7.5kg / mm 2 , the glass is especially suitable for the manufacture of f...

Embodiment 2

[0035] In a preferred embodiment of the present invention, the following method is used to manufacture display glass.

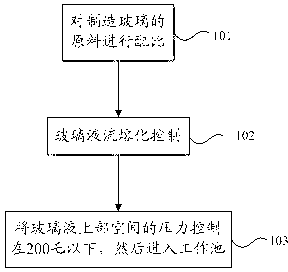

[0036] The glass is formed by the conventional float glass process, and the specific manufacturing method is as follows: figure 1 Shown:

[0037] Step 101, proportioning the raw materials for making glass. The glass batch material of the liquid crystal display substrate glass contains quartz sand, alumina, boric acid, calcium carbonate, barium carbonate and mixed rare earth oxides, and the weight percentage of the basic glass oxide is: 60SiO 2 、9B 2 o 3 , 12Al 2 o 3 , 7MgO, 6CaO, 3BaO, 1.5Y 2 o 3 , 0.005R 2 O (R = Li, Na or K), 1SnO 2 , 0.45CeO 2 .

[0038] Step 102, glass melt flow melting control. The melting time of the glass flow is controlled to be about 6-8 hours. The melting temperature in the melting pool is 1550°C, the clarifying and homogenizing temperature is 1590°C, the molding temperature is 1240°C, the liquidus temperature is 1130°C,...

Embodiment 3

[0042] The preparation method of the glass is the same as in Example 2, the difference is that the glass basic oxide component content of the liquid crystal display substrate glass is different, and the weight percentage of the basic glass oxide is: 58SiO 2 、10B 2 o 3 , 13Al 2 o 3 , 6MgO, 7CaO, 2.5BaO, 2Y 2 o 3 , 0.1R 2 O (R = Li, Na or K), 1SnO 2 , 0.4CeO 2 .

[0043] The performance indicators of the prepared LCD substrate glass are as follows: (1) Strain temperature: 670°C (2) Average linear thermal expansion coefficient (α20~300°C): 37×10-7 / °C (3) Density: 2.377g / cm3 (4) The modulus of elasticity is 7.5kg / mm2, the glass is especially suitable for manufacturing flat panel display substrate glass.

[0044] Among them, the density ρ of the glass is measured by the Archimedes method; the thermal expansion coefficient at 20-300°C is measured by a dilatometer, expressed as an average expansion coefficient; the strain point of the glass is measured by the bent beam metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com