Rapid heat dissipation coating and preparation method thereof

A heat-dissipating coating and fast technology, applied in coatings and other directions, can solve problems such as poor heat dissipation of coatings, and achieve the effects of reducing heat, saving energy consumption, and producing safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

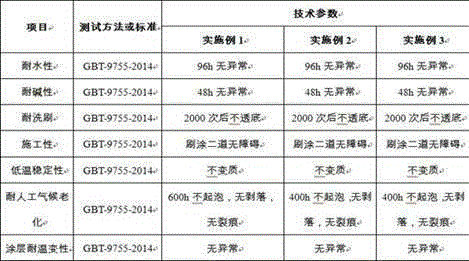

Examples

preparation example Construction

[0062] Correspondingly, the embodiment of the present invention also provides a preparation method of the above rapid heat dissipation coating. This preparation method comprises the steps:

[0063] Step S01: Obtain each component according to the components and contents in the rapid heat dissipation coating of the embodiment of the present invention described above;

[0064] Step S02: Mixing the weighed components.

[0065] In one embodiment, in the above step S02, each component is mixed according to the following sequence:

[0066] Add dispersant, wetting agent, bactericide, antifungal agent, defoamer, cellulose, pH regulator, composite material, filler, emulsion, film-forming aid, antifreeze, thickener to the water component in sequence until all components are evenly mixed. The preparation according to the order of addition can make the rapid heat dissipation coating system formed by the preparation stable.

[0067] In order to further improve the dispersibility of eac...

Embodiment 1

[0073] A rapid heat dissipation coating and a preparation method thereof. The rapid heat dissipation coating contains the following components by weight:

[0074] 20 parts of water

[0075] Dispersant 0.5 parts

[0076] Wetting agent 0.2 parts

[0077] 0.1 part of fungicide

[0078] Antifungal agent 0.1 part

[0079] 0.2 part of defoamer

[0080] 0.25 parts of cellulose

[0081] 0.15 parts of pH regulator

[0082] Composite 20 parts

[0083] Filling 24 parts

[0084] 30 parts of lotion

[0085] Coalescing aid 2 parts

[0086] Antifreeze 2.0 parts

[0087] Thickener 0.5 part.

[0088] Among them, the composite material is a compound made of titanium dioxide and graphene; the filler is calcined kaolin; The agent is 1124 (Rohm and Haas), the wetting agent is BD405 (Dow Chemical), the bactericide is LXE (Dow Chemical), the antifungal agent is isothiazolinone derivatives, and the defoamer is mineral oil. Foaming agent, cellulose is Natrosol ? 250 hydroxyethyl cellulo...

Embodiment 2

[0098] A rapid heat dissipation coating and a preparation method thereof. The rapid heat dissipation coating contains the following components by weight:

[0099] 30 parts of water

[0100] Composite 10 parts

[0101] Filling 30 parts

[0102] Lotion 25 parts

[0103] Coalescing aid 2 parts

[0104] 1 part antifreeze

[0105] Thickener 0.3 part

[0106] Dispersant 0.4 parts

[0107] Wetting agent 0.1 part

[0108] 0.3 parts of fungicide

[0109] Antifungal agent 0.2 parts

[0110] 0.1 part of defoamer

[0111] 0.5 parts of cellulose

[0112] 0.1 part of pH regulator.

[0113] Its preparation method is carried out with reference to the method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com