Modification method for cladding cylindrical surface of bar based on electron beam toroidal gun

An electron beam ring gun, electron beam cladding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of easy cracking, coarse structure, stress generation, etc., to improve corrosion resistance, uniform heating, The effect of reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

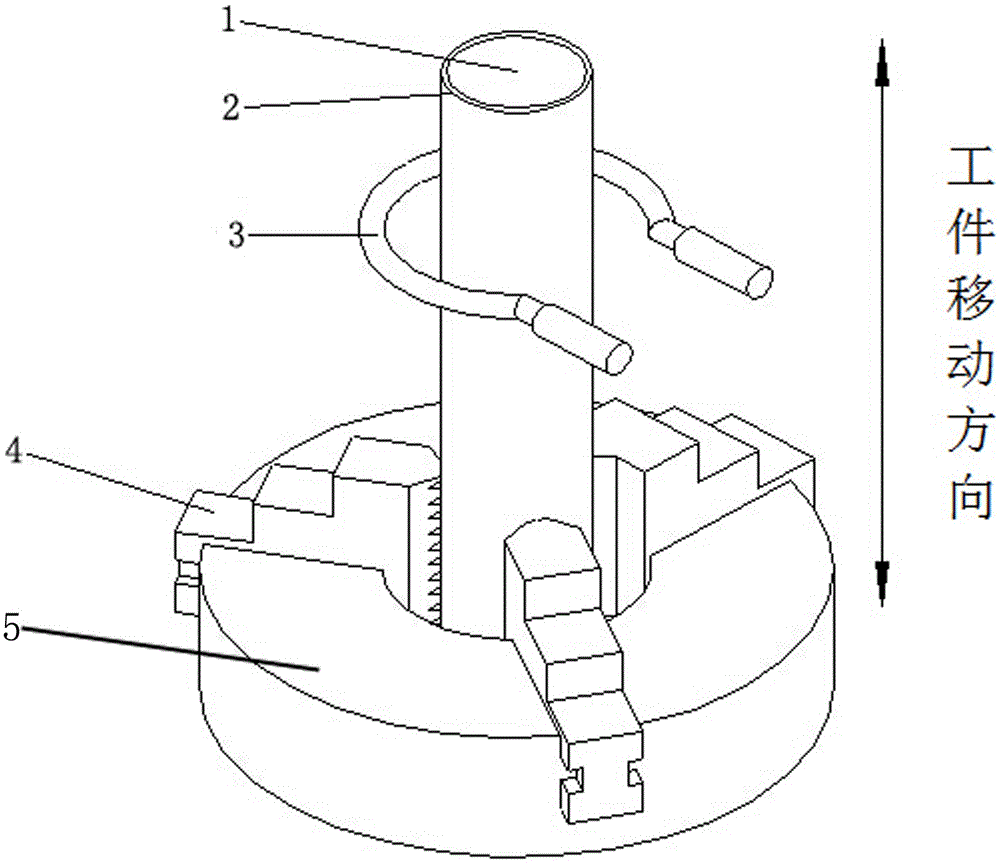

[0029] refer to figure 1 , a modification method based on electron beam annular gun cladding bar cylindrical surface, comprising the following steps:

[0030] 1) Preparation of the matrix: take the bearing steel GCr15 bar as the matrix 1, turn the surface of the matrix 1 to remove the surface oxide layer; then put it into kerosene for cleaning, remove the lubricating oil remaining in the process, and then grind it to eliminate the turning process The traces of cutting processing brought by it; then roughen it with sandpaper, then remove the surface oil, and put it in a dryer for later use.

[0031] 2) Pre-coating: heat the nickel-based powder, and make the coating slurry from the heated and melted modified layer powder; perform sandblasting on the surface of the substrate 1 in step 1), and then use an air compressor to apply the coating The layer slurry is sprayed on the surface of the substrate 1 to form a coating 2. In order to eliminate the air entering the coating 2 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com