A method for preparing high-performance nano-silver wire transparent conductive film by microwave welding

A technology of transparent conductive film and nano-silver wire, applied in the direction of equipment used to manufacture conductive/semiconductive layers, conductive materials dispersed in non-conductive inorganic materials, conductive layers on insulating carriers, etc., can solve the problem of affecting flexible display The electrical stability of the device, the reduction of the electrical properties of the transparent conductive film, and the degradation of the optical properties, etc., achieve the effects of excellent solvent wiping resistance, fast heating speed, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

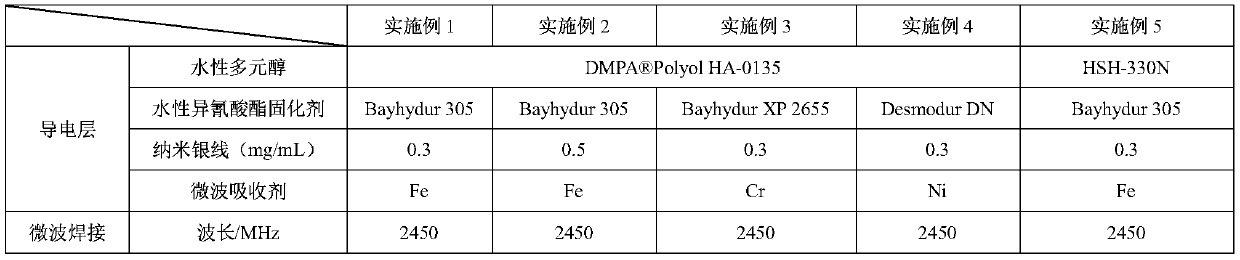

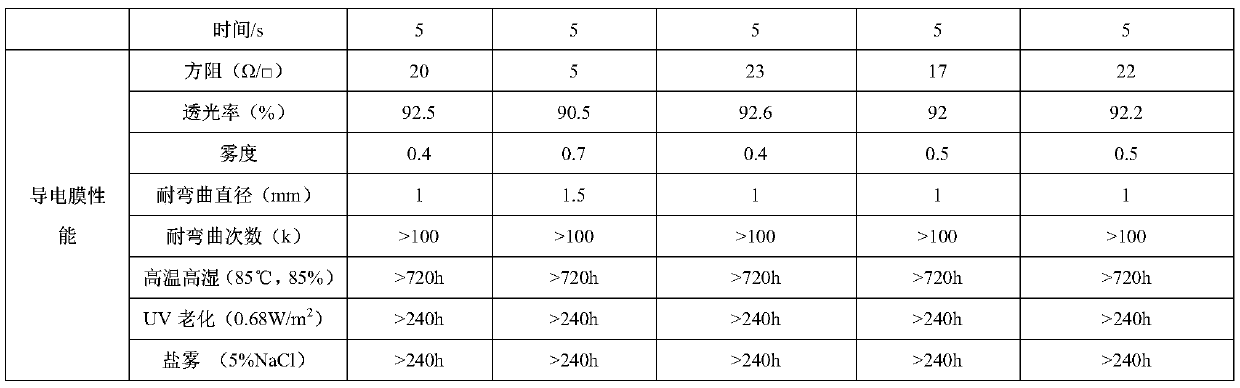

Embodiment 1

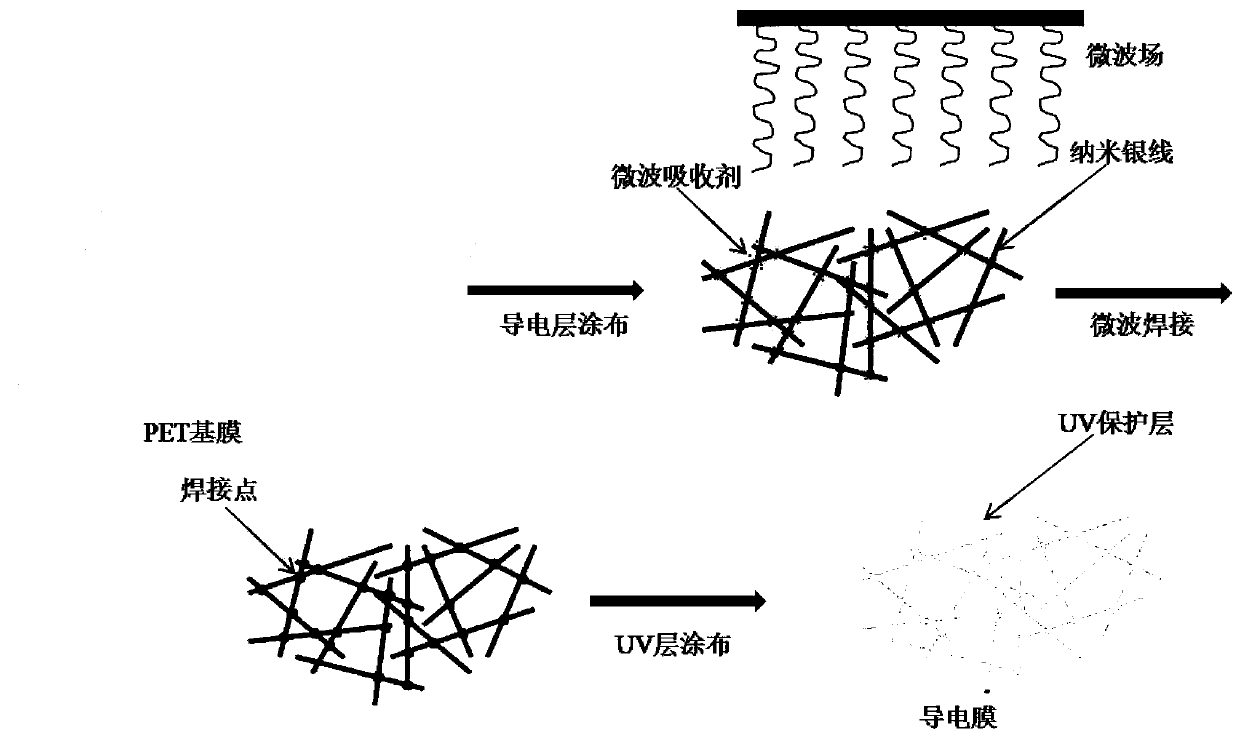

[0040] This embodiment prepares high-performance silver nano wire transparent conductive film according to the following steps:

[0041] Step A, conductive layer coating

[0042] 3g of water-based polyester polyol ( Polyol HA-0135, Jiangshan Chemical), 7g water-based isocyanate curing agent Bayhydur 305 and 5000g deionized water were added to the dispersion tank, and mechanically stirred; then added 1.5g AgNWs (wire diameter 20nm, aspect ratio 1000- 2000, from Hefei Microcrystalline Material Technology Co., Ltd. (brand WJAG1, commercially available) and 30mg of nano-iron particles (5nm), continue to stir uniformly, and finally pass through a 800-mesh filter to prepare conductive ink;

[0043] Use dimple coating to uniformly coat the conductive ink on the non-hardened surface of the PET cured film, and then dry it in an IR oven at 120°C for 15s to form a conductive layer;

[0044] Step B. Microwave welding

[0045] Put the PET hardened film formed with a conductive layer in...

Embodiment 2

[0050] This embodiment prepares high-performance silver nano wire transparent conductive film according to the following steps:

[0051] Step A, conductive layer coating

[0052] 4g water-based polyester polyol ( Polyol HA-0135, Jiangshan Chemical), 9g water-based isocyanate curing agent Bayhydur 305 and 5000g deionized water were added to the dispersion tank, and mechanically stirred; then 2.5g AgNWs (wire diameter 20nm, aspect ratio 1000- 2000, from Hefei Microcrystalline Materials Technology Co., Ltd., brand WJAG1, available in the market) and 50mg of nano-iron particles (5nm), continue to stir uniformly, and finally pass through a 800-mesh filter to prepare conductive ink;

[0053] Use dimple coating to uniformly coat the conductive ink on the non-hardened surface of the PET cured film, and then dry it in an IR oven at 120°C for 15s to form a conductive layer;

[0054] Step B. Microwave welding

[0055] Put the PET hardened film formed with a conductive layer into a mi...

Embodiment 3

[0060] This embodiment prepares high-performance silver nano wire transparent conductive film according to the following steps:

[0061] Step A, conductive layer coating

[0062] 6g water-based polyester polyol ( Polyol HA-0135, Jiangshan Chemical), 14g water-based isocyanate curing agent Bayhydur XP 2655 and 5000g deionized water are added to the dispersion tank, mechanically stirred; then add 1.5g AgNWs (wire diameter 20nm, aspect ratio 1000) while stirring -2000, from Hefei Microcrystalline Materials Technology Co., Ltd., brand WJAG1, available in the market) and 30mg nano-chromium particles (7nm), continue to stir uniformly, and finally pass through a 800-mesh filter screen to obtain conductive ink;

[0063] Use dimple coating to uniformly coat the conductive ink on the non-hardened surface of the PET cured film, and then dry it in an IR oven at 120°C for 15s to form a conductive layer;

[0064] Step B. Microwave welding

[0065] Put the PET hardened film formed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com