Preparation method for SiO2 anti-reflection film having simulated bulge structure

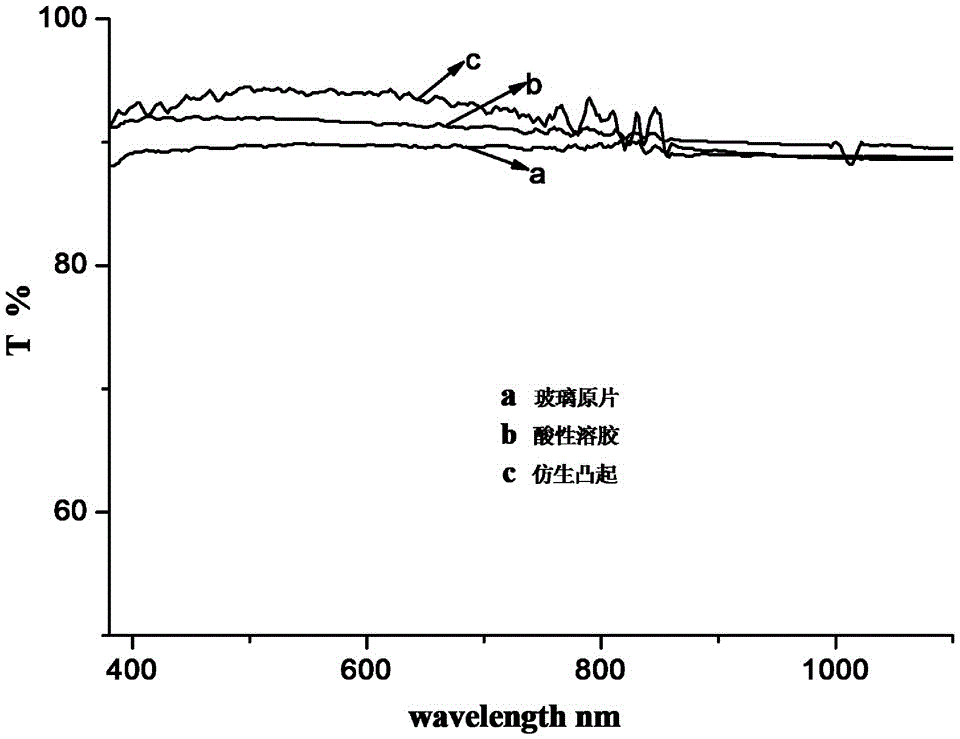

A technology of anti-reflection film and bionic protrusions, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high strength and low transmittance of anti-reflection film, so as to improve the anti-fouling self-cleaning ability and improve the compactness , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, mix 1.2 mL of deionized water and 90 mL of ethanol evenly, adjust the pH value of the mixture to 2.0 with concentrated hydrochloric acid, and add 12 mL of TEOS dropwise under stirring at a speed of 300 r / min, TEOS and H 2 O undergoes hydrolysis and condensation reaction, but the reaction rate is very slow. In this embodiment, concentrated hydrochloric acid can be added to increase the rate of hydrolysis reaction. Stirring and homogenization are continued for 6 hours, and standing and aging for 4 to 6 days.

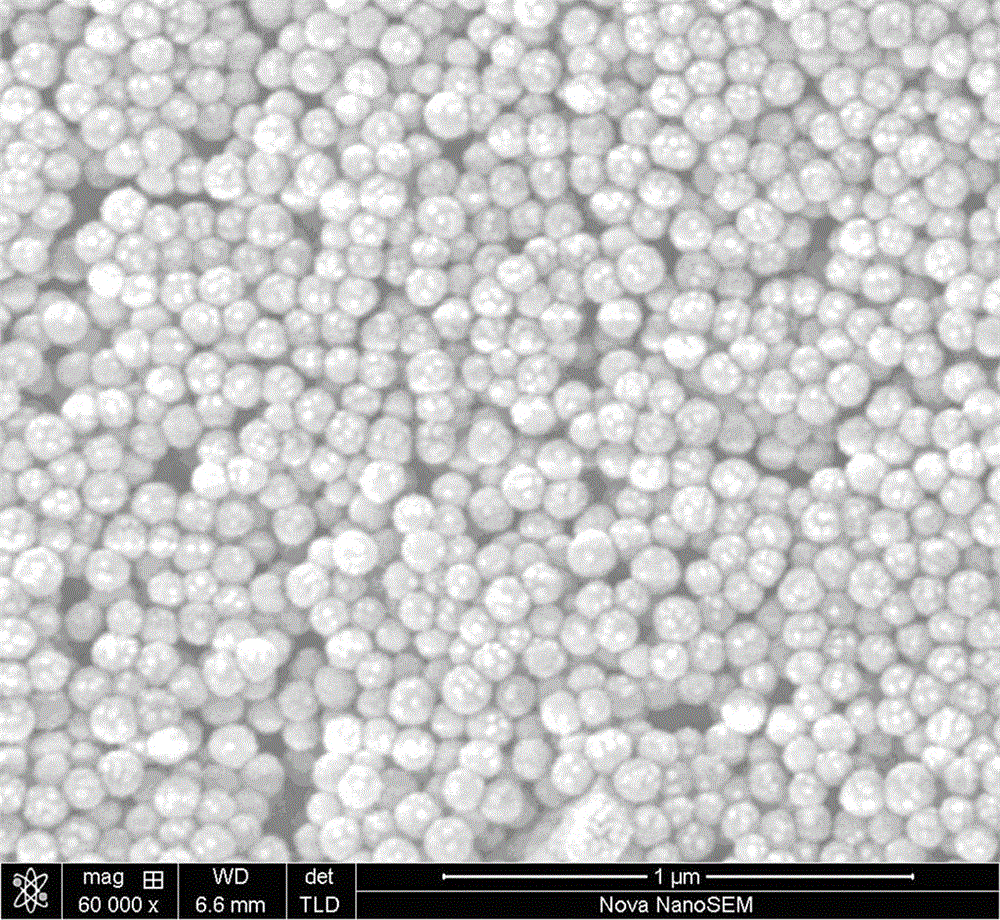

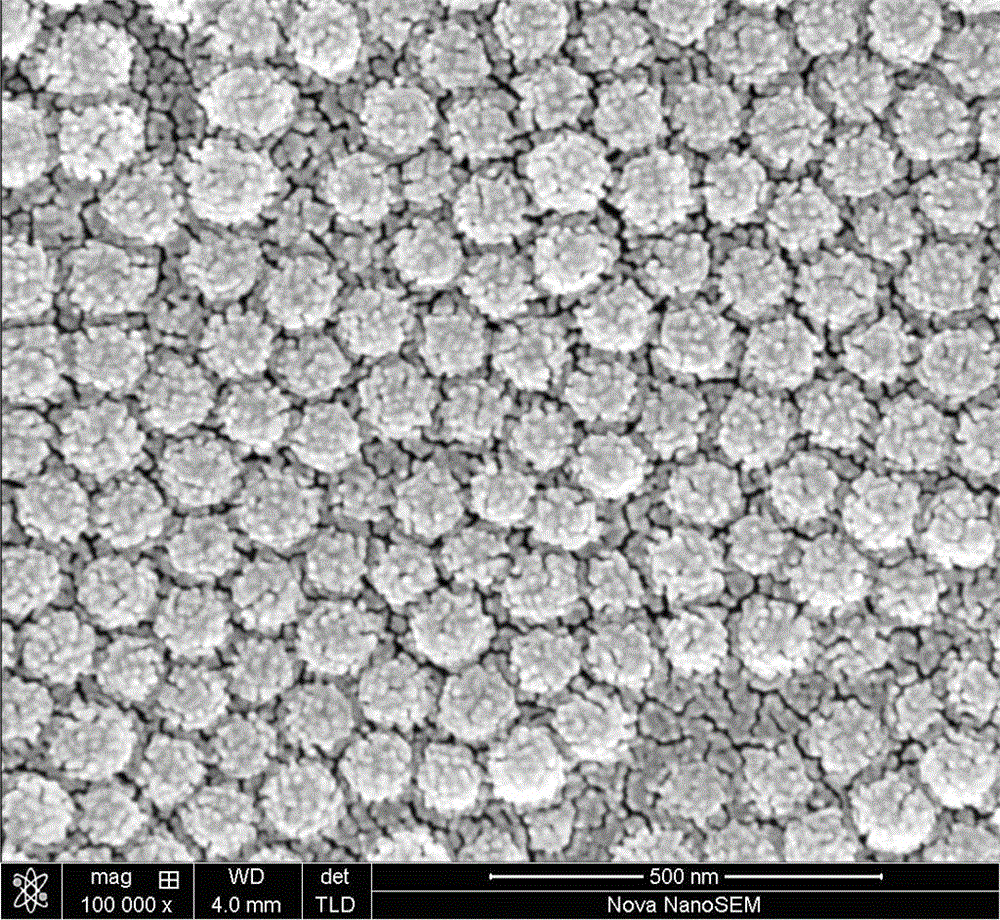

[0029] Dissolve sodium acetate trihydrate in water to make a 0.021mol / L aqueous solution, add 3.2g of cetyltrimethylammonium bromide under constant temperature heating and stirring in an oil bath at 85°C, continue heating and stirring at constant temperature for 2 hours , add silicate 5mL dropwise at a rate of 1.5mL / min, continue to heat and stir in an oil bath at 85°C for 24h, then perform centrifugal ultrasonic washing on the sample, wash three times with al...

Embodiment 2

[0032] First, mix 5 mL of deionized water and 200 mL of ethanol evenly, adjust the pH value of the mixture to 2.0 with concentrated hydrochloric acid, and add 22 mL of TEOS dropwise under stirring at a speed of 300 r / min, TEOS and H 2 O undergoes hydrolysis and condensation reaction, but the reaction rate is very slow. In this embodiment, concentrated hydrochloric acid can be added to increase the rate of hydrolysis reaction. Stirring and homogenization are continued for 6 hours, and standing and aging for 4 to 6 days.

[0033] Dissolve sodium acetate trihydrate in water to make a 0.042mol / L aqueous solution, add 6.2151g of hexadecyltrimethylammonium bromide under constant temperature heating and stirring in an oil bath at 85°C, and continue heating and stirring at a constant temperature to homogenize for 2 hours , add silicate 22mL dropwise at a rate of 1.5mL / min, continue heating and stirring in an oil bath at 85°C for 24h, then perform centrifugal ultrasonic washing on the s...

Embodiment 3

[0036] First, mix 3mL of deionized water and 330mL of ethanol evenly, adjust the pH value of the mixture to 2.0 with concentrated hydrochloric acid, and add 30mL of TEOS drop by drop under stirring at a speed of 300r / min, TEOS and H2O undergo hydrolysis and condensation reaction , but this reaction rate is very slow. In this embodiment, adding concentrated hydrochloric acid can increase the hydrolysis reaction rate, continue to stir and homogenize for 6 hours, and leave to age for 4 to 6 days.

[0037] Dissolve sodium acetate trihydrate in water to make a 0.028mol / L aqueous solution, add 3.0g of cetyltrimethylammonium bromide under constant temperature heating and stirring in an oil bath at 85°C, and continue heating and stirring at a constant temperature to homogenize for 2 hours , add silicate 6mL dropwise at a rate of 1.5mL / min, continue to heat and stir in an oil bath at 85°C for 24h, then perform centrifugal ultrasonic washing on the sample, wash three times with alcohol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com