Nickel-based catalyst for improving performance of direct borohydride fuel cell

A nickel-based catalyst and fuel cell technology, applied in the field of electrochemical applications, can solve the problems of low fuel discharge efficiency, low direct oxidation performance, large electrode reaction charge transfer resistance, etc., to improve discharge efficiency, enhance direct oxidation performance, The effect of increasing catalytically active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

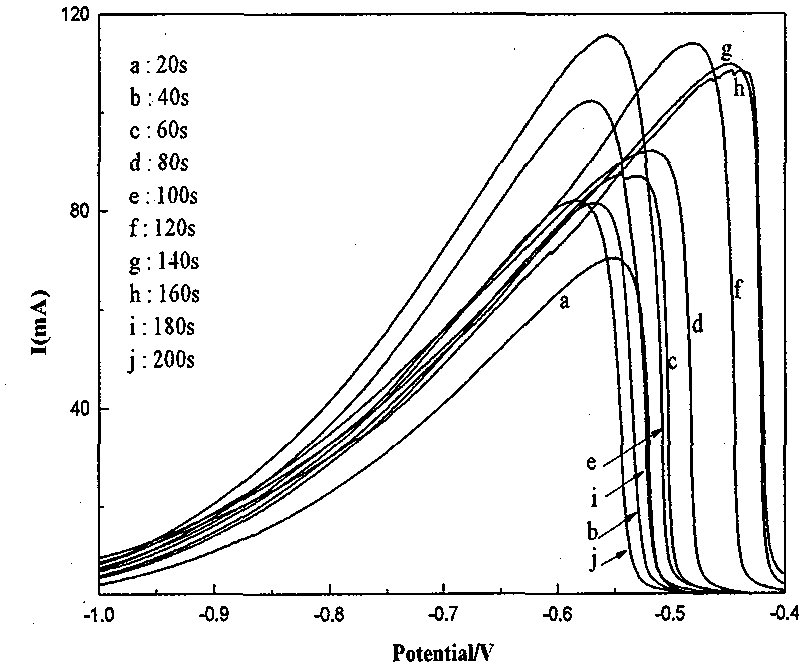

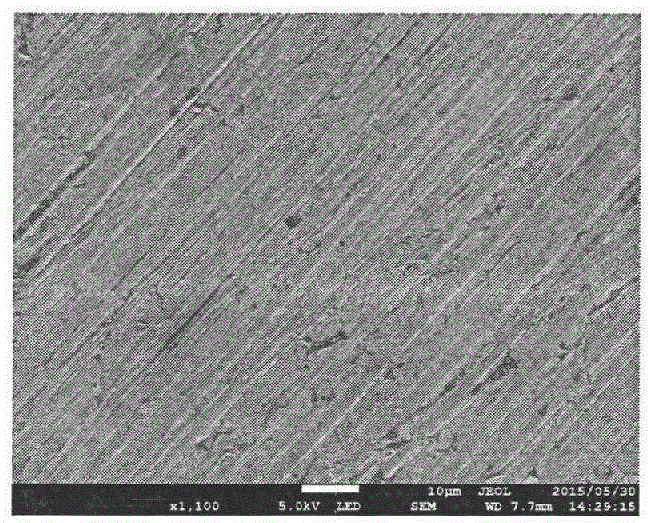

[0020] Under normal pressure, the temperature is in the range of 293.15 ~ 313.15K, and the configuration is 0.2mol / dm 3 NiSO 4 solution. 2cm 2 The smooth Ni sheet (as the working electrode) is placed in the above solution, with the Ni sheet as the counter electrode and the silver / silver chloride electrode as the reference electrode, Ni is deposited on the metal nickel sheet by the constant potential (-0.8V) method. into a nickel-based catalyst. Weigh an appropriate amount of sodium borohydride (NaBH 4 ), and dissolve it in 2mol / dm 3 In sodium hydroxide (NaOH) solution, make 0.27mol / dm 3 NaBH 4 solution, mixed well as direct NaBH 4 Electrolyte for fuel cells. 2cm 2 The Ni catalyst and deposited Ni catalyst were used as the working electrode, the mercury / mercury oxide electrode was used as the reference electrode, and the graphite rod was used as the auxiliary electrode. Linear potential sweep (LSV) was used for performance testing.

[0021] The Ni catalyst prepared by...

Embodiment 2

[0025] Under normal pressure, the temperature is in the range of 293.15 ~ 313.15K, and the configuration is 0.2mol / dm 3 NiSO 4 solution. 2cm 2 The smooth Ni sheet (as the working electrode) is placed in the above solution, with the Ni sheet as the counter electrode and the silver / silver chloride electrode as the reference electrode, Ni is deposited on the metal nickel sheet by the constant potential (-0.8V) method. into a nickel-based catalyst. Weigh an appropriate amount of NaBH 4 , and dissolve it at 2mol / dm 3 In the NaOH solution, make 0.27mol / dm 3 NaBH 4 solution, mixed well as direct NaBH 4 Electrolyte for fuel cells. 2cm 2 The Ni catalyst and deposited Ni catalyst were used as the working electrode, the mercury / mercury oxide electrode was used as the reference electrode, and the graphite rod was used as the auxiliary electrode. Cyclic voltammetry was used for performance testing.

[0026] Figure 6 is BH under the action of Ni catalyst 4 - Multiple cyclic vo...

Embodiment 3

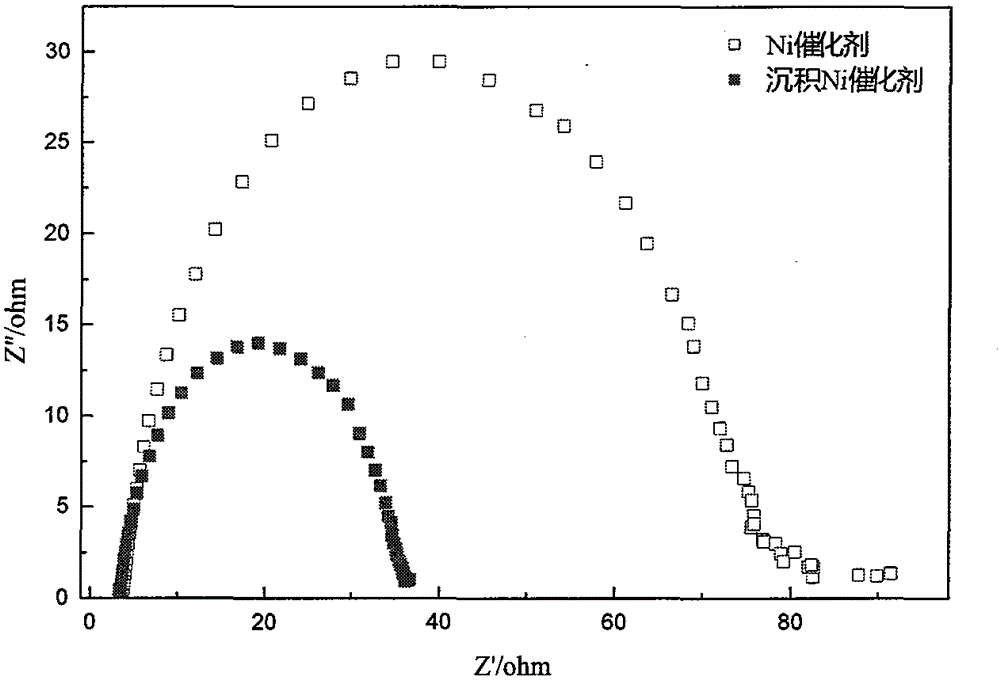

[0028] Under normal pressure, the temperature is in the range of 293.15 ~ 313.15K, and the configuration is 0.2mol / dm3 NiSO 4 solution. 2cm 2 The smooth Ni sheet (as the working electrode) is placed in the above solution, with the Ni sheet as the counter electrode and the silver / silver chloride electrode as the reference electrode, Ni is deposited on the metal nickel sheet by the constant potential (-0.8V) method. into a nickel-based catalyst. Weigh an appropriate amount of NaBH 4 , and dissolve it at 2mol / dm 3 In the NaOH solution, make 0.27mol / dm 3 NaBH 4 solution, mixed well as direct NaBH 4 Electrolyte for fuel cells. 2cm 2 The Ni catalyst and the deposited Ni catalyst are used as working electrodes, the mercury / mercury oxide electrode is used as the reference electrode, and the graphite rod is used as the auxiliary electrode, and the AC impedance spectroscopy performance test is performed.

[0029] Figure 8 is BH under the action of different catalysts 4 - AC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com