Vortex laser based on laser medium center zero gain structure

A laser medium and zero-gain technology, which is applied to the structure/shape of lasers, laser components, and optical resonators, can solve the problems of high laser threshold, difficult high-power operation, and large intracavity loss to achieve high laser efficiency. , wide application range, no energy waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

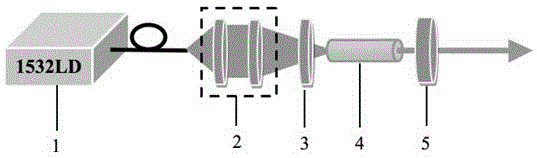

[0021] Implementation Case 1: A ~1.6μm vortex laser based on Er:YAG ceramics with zero-gain center structure

[0022] Among them, the solid-state laser medium 4 is a 1at.% doped Er: YAG ceramic with a zero-gain center structure, and its two light-transmitting end faces are plated with a light transmittance of 1500nm-1700nm band for pump light and oscillation light ≥ 99 % anti-reflection coating; the input mirror 3 near the pump end is coated with a dielectric film with a transmittance of ≥99% for the pump light at 1532nm, and the other end close to the laser medium is coated with a dielectric film with a reflectance of ≥99% for 1500-1700nm ; The surface of the output mirror 5 close to the laser medium is coated with a partially reflective medium film with a transmittance of 10% for 1600-1700nm.

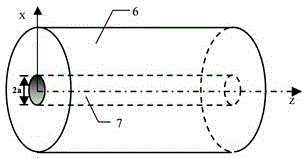

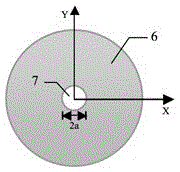

[0023] The zero-gain center structure laser medium 4 is Er:YAG transparent ceramics with a doping concentration of 1 at.%, and the absorption length of the ceramics is 15 mm. The zer...

Embodiment example 2

[0039] Implementation Case 2: A ~2μm vortex laser based on a zero-gain center structure Tm:YAG crystal

[0040] The pump source 1 is a semiconductor laser diode LD with an output wavelength of 785nm, the solid laser medium 4 is a 3.3at.% doped Tm of a zero-gain center structure: YAG crystal, and the input mirror 3 is plated near the pump end to A dielectric film with a pump light 700-900nm transmittance ≥ 99%, the other end close to the laser medium is coated with a dielectric film with a reflectivity ≥ 99% for 1900-2100nm; the surface of the output mirror 5 close to the laser medium is coated with 1900 nm Partially reflective dielectric film with 10% transmittance at -2100nm.

[0041] The zero gain center structure laser medium 4 is a Tm:YAG transparent crystal with a doping concentration of 3.3 at.%, and the absorption length of the crystal is 10 mm. The zero-gain center structure is realized by punching a hole in the center of the rod-shaped Tm:YAG crystal, and the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com