Semi-solid electrodes having high rate capability

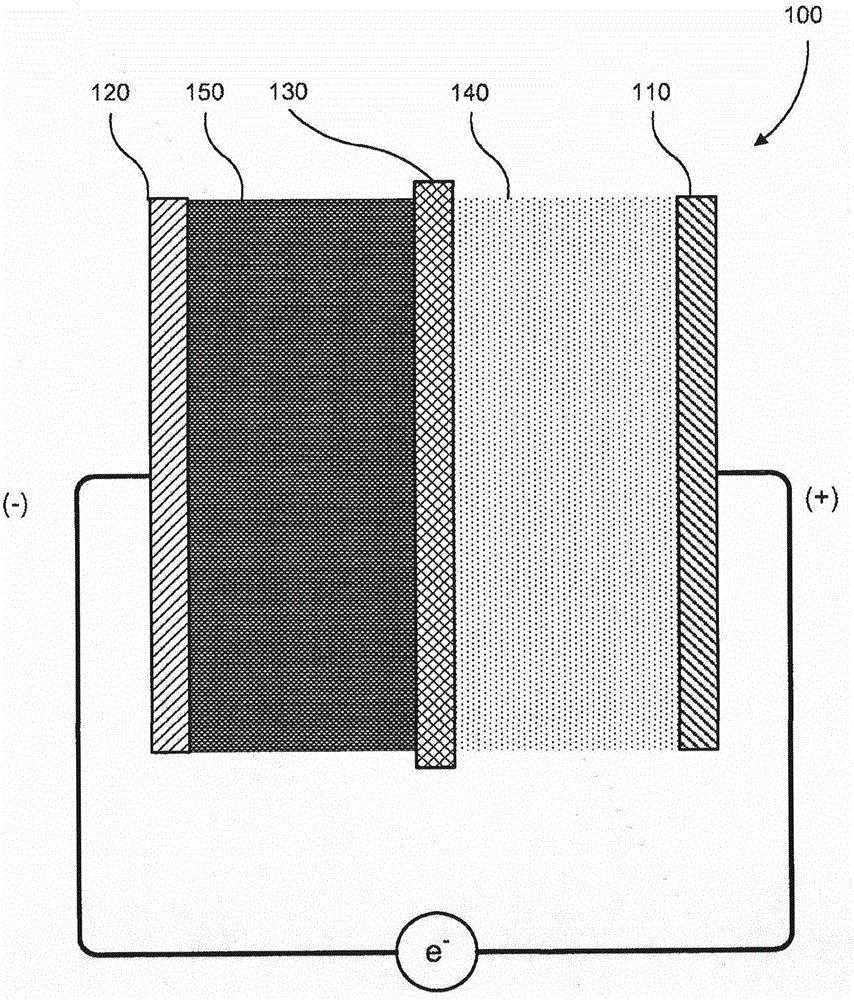

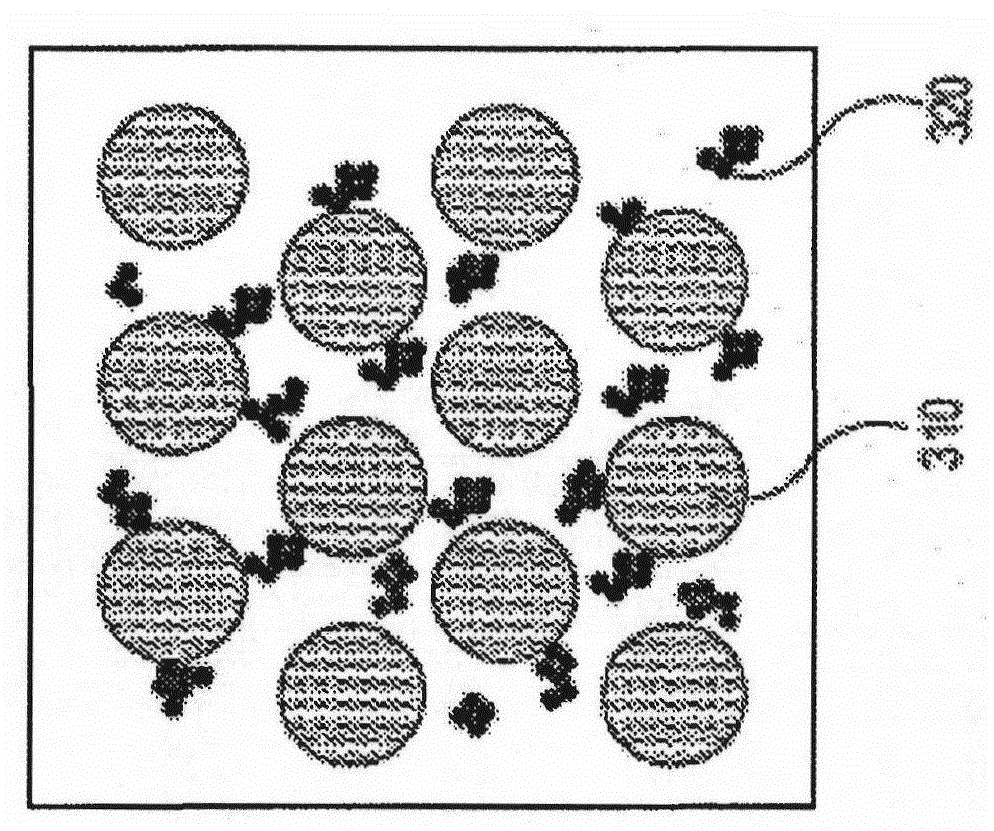

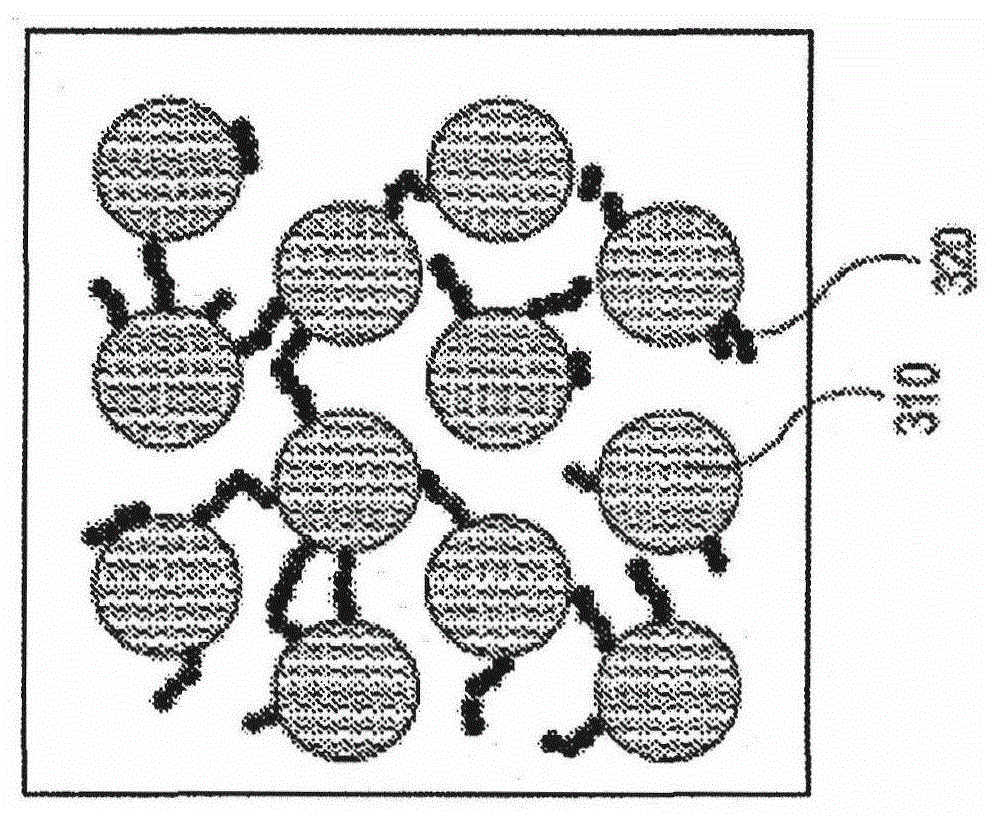

A semi-solid, multiplier technology, applied to active material electrodes, battery electrodes, circuits, etc., can solve problems such as low capacity, low energy density, and reduced ion conductivity of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] Electrochemical half-cell Example 1 (also referred to as "Example 1") was prepared using a semi-solid cathode and a Li metal anode. The LFP semi-solid cathode was prepared by combining 45% by volume of LFP and 2% by volume of carbon black with ethylene carbonate / dimethyl carbonate / LiPF 6 Base electrolyte mix. The cathode slurry was prepared using a batch mixer with roller sharpening fittings. The mixing is carried out at 100 rpm for about 2 minutes. Semi-solid slurry has a mixing index greater than 0.9 and 1.5×10 -4 S / cm conductivity. The slurry was made into electrodes about 250 μm thick and tested in a Swagelok battery configuration against Li metal anodes. A Maccor battery tester was used to test the battery and cycled between the voltage range of V=2-4.2V. The battery is charged using a constant current and constant voltage (CC-CV) program, where the constant current rate is C / 10 and C / 8 for the first two cycles, and C / 5 for the subsequent cycles. After constant ...

Embodiment 2

[0166] Electrochemical half-cell Example 2 (also referred to as "Example 2") was prepared using a semi-solid cathode and a lithium metal anode. The cathode slurry was prepared as follows: Li(Mn, Co, Ni) O 2 And 8 vol% carbon additive with ethylene carbonate / dimethyl carbonate / LiPF 6 Base electrolyte mix. The cathode slurry was prepared using a batch mixer equipped with roller sharpening fittings. The mixing was carried out at 100 rpm for about 4 minutes. The slurry was made into electrodes about 250 μm thick and tested in a Swagelok battery configuration against Li metal anodes. A Maccor battery tester was used to test the battery and cycled between the voltage range of V=2-4.3V. Use the CC-CV program to charge the battery, where the constant current part is C / 10 and C / 8 for the first two cycles, and C / 5 for the subsequent cycles. After the constant current charging step, the constant voltage is maintained at 4.2V until the charging current drops below C / 20. The battery is ...

Embodiment 3

[0168] Electrochemical Full Cell Example 3 (also referred to as "Example 3") consists of 35 vol% Li(Ni, Mn, Co) O 2 The semi-solid cathode is prepared so that the semi-solid cathode has a thickness of about 250 μm. Compared to a semi-solid anode prepared with 40% by volume of graphite and 2% by volume of carbon additives, the anode has a thickness of about 500 μm. The NMC semi-solid cathode was prepared by combining 35 vol% NMC and 8 vol% carbon black with ethylene carbonate / dimethyl carbonate / LiPF 6 Base electrolyte mix. The cathode slurry is prepared using a batch mixer equipped with a roll blade. The mixing was carried out at 100 rpm for 4 minutes. The graphite semi-solid anode is prepared by mixing 40 vol% graphite and 2 vol% carbon black using the same electrolyte as the cathode. The anode slurry formulation was mixed at 100 rpm for about 30 seconds, producing a semi-solid anode suspension. The electrode is used to form an NMC-graphite-based electrochemical full battery,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com