Bean curd production system

A production system, tofu technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as fast reaction speed, difficulty in unpacking, and difficulty in mixing, so as to reduce energy consumption, reduce production links, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The tofu production system of the present invention is provided with a soybean milk production line and a soybean milk filling line. The soybean milk production line can adopt the production line structure in the prior art. Equipment, and temporary storage equipment can also be set up to expand production capacity.

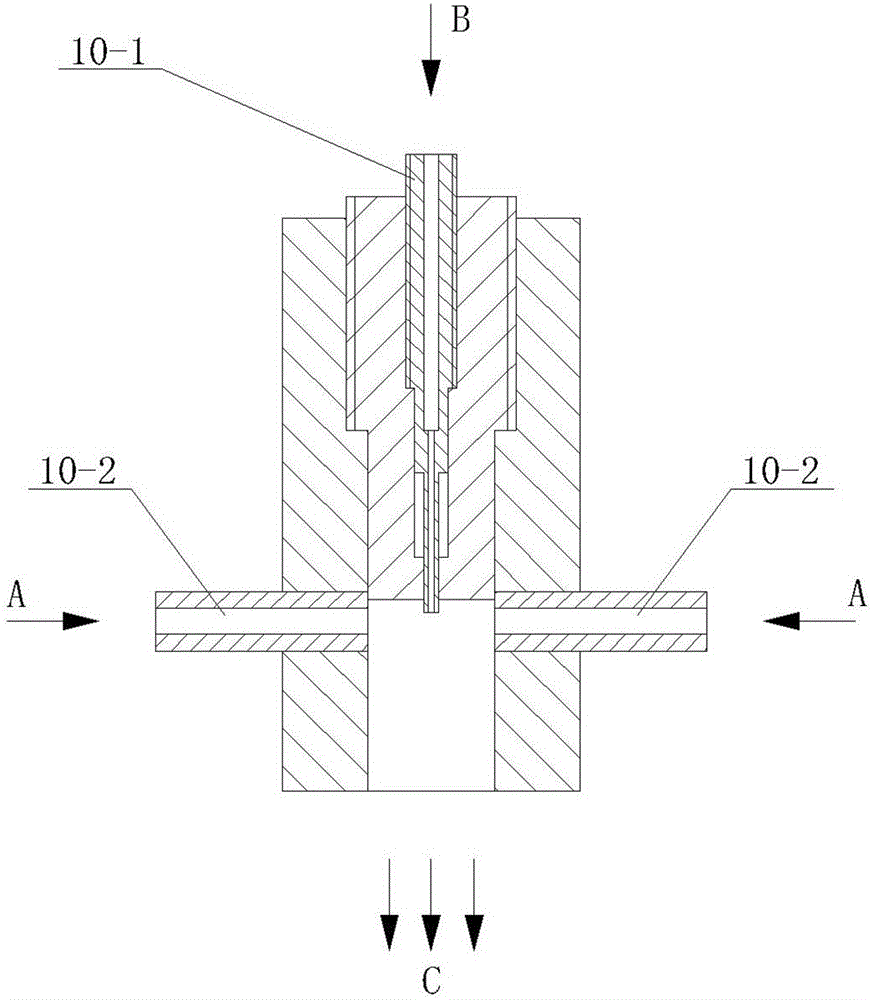

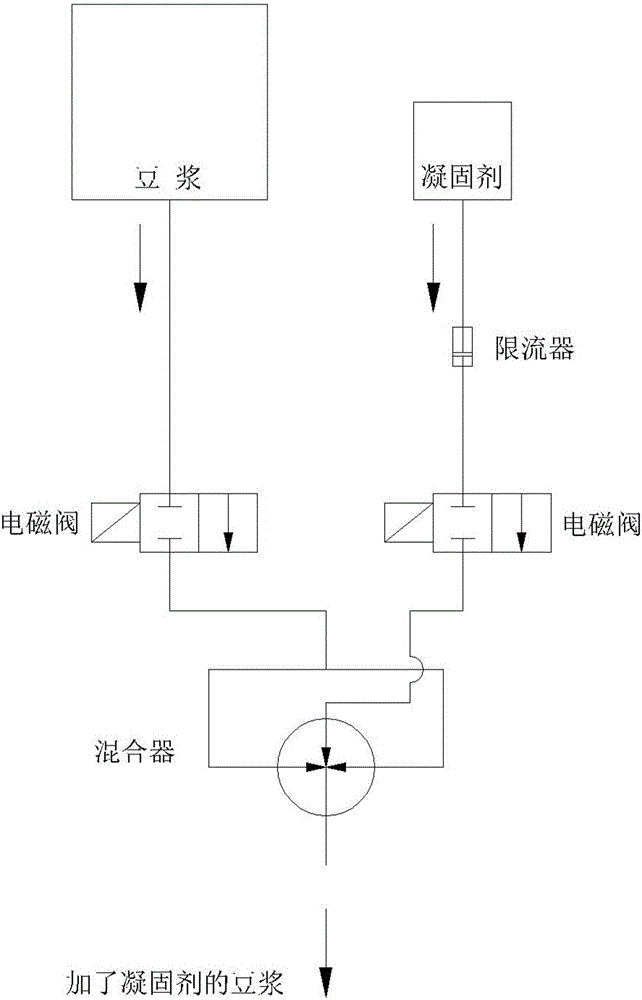

[0036] The soymilk production line is connected to a mixer, which is provided with a volume-adjustable mixing chamber, and the soymilk that has completed the cooking process is poured into the mixer quantitatively, forming several streams of soymilk that collide with each other in the mixing chamber, and the coagulant is proportionally It is injected into the mixing chamber at the same time, and the coagulant flow is introduced into the impact area of the soy milk flow, and the soy milk flow colliding with each other then forms a turbulent flow to promote the mixing of the soy milk and the coagulant; the mixed soy milk is output from the mixer and enters t...

Embodiment 2

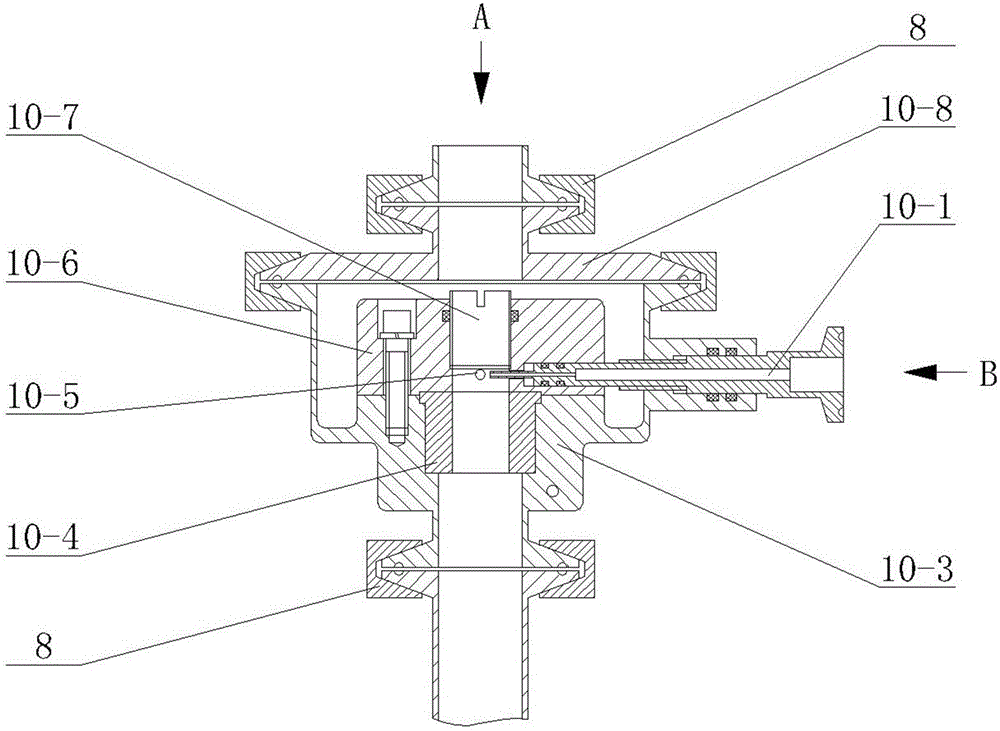

[0056] Regarding the arrangement of the coagulant introduction pipe on the inner core, it is also possible to adopt a structure in which the mixing chamber is inserted from the top of the inner core, and the soymilk injection hole can still adopt a horizontal direction. Correspondingly, the axis of the coagulant introduction pipe is perpendicular to the soymilk injection hole. The plane where the axis is located and points to the intersection of multiple injection hole axes. .

[0057] If an adjusting bolt is installed above the mixing chamber to change the volume, the coagulant inlet pipe can be installed together with the adjusting bolt. As the adjusting bolt moves up and down, the coagulant inlet pipe can adjust the depth inserted into the mixing chamber, thereby adjusting The distance between the output end and the plane where the axis of the soya-bean milk injection hole is located can adjust the mixing intensity of the coagulant and soya-bean milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com