Yunnan olive powder, preparation method and use

A technology of Yunnan olive and powder, applied in the field of preparation of Yunnan olive powder, can solve the problems of easily destroying the heat-sensitive components of Yunnan olive, and achieve the effects of beautiful color, easy acceptance and unique flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

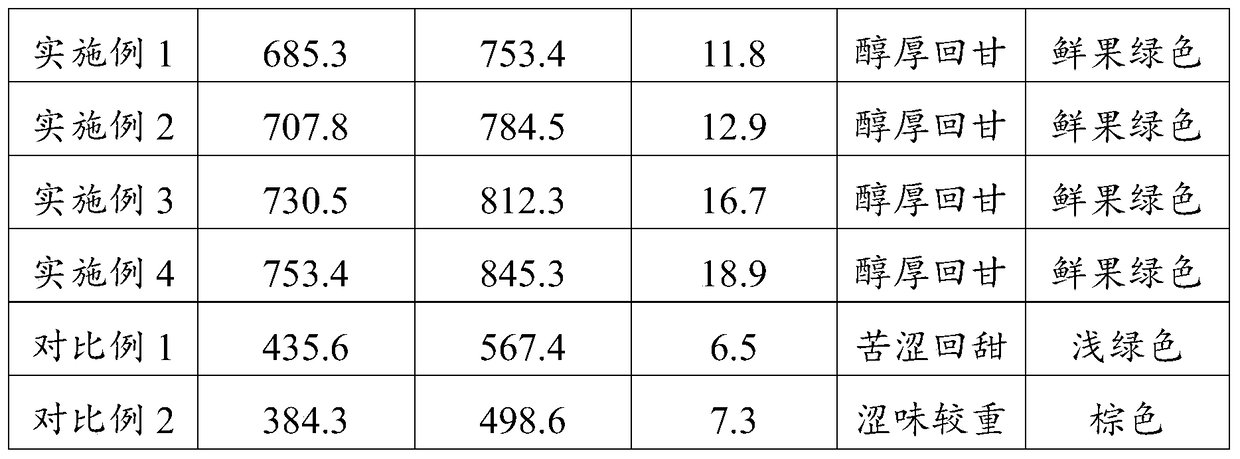

Examples

Embodiment 1

[0041] (1) soak ripe, complete, non-rotten, non-mildewed Yunnan olive fruit with 0.1wt% hydrogen peroxide aqueous solution for 10 minutes, rinse with clear water, remove the core with a pitting machine, and slice;

[0042] (2) The sliced Yunnan olive fruit is freeze-dried at -20°C and 30Pa using a vacuum freeze-drying machine to obtain a dried Yunnan olive fruit with a water content of 15% by weight;

[0043] (3) Grinding the obtained dried product at -10°C to a D50 of about 45 microns to obtain Yunnan olive powder.

Embodiment 2

[0045] (1) soak ripe, complete, non-rotten, non-mildewed Yunnan olive fruit with 0.5wt% hydrogen peroxide aqueous solution for 3 minutes, rinse with clear water, remove the pits with a pitting machine, and slice;

[0046] (2) The sliced Yunnan olive fruit is freeze-dried at -40° C. and 150 Pa using a vacuum freeze-drying machine to obtain a dried Yunnan olive fruit with a water content of 5 wt %;

[0047] (3) Grinding the obtained dried product at -40°C to a D50 of about 45 microns to obtain Yunnan olive powder.

Embodiment 3

[0049] (1) soak ripe, complete, non-rotten, non-mildewed Yunnan olive fruit with 0.6wt% hydrogen peroxide aqueous solution for 5 minutes, rinse with clear water, remove the core with a pitting machine, and slice;

[0050] (2) The sliced Yunnan olive fruit was pre-frozen at -80° C. for 8 minutes with a vacuum freeze-drying machine, and then freeze-dried at -10° C. and 100 Pa to obtain a dry product with a water content of 10 wt%.

[0051] (3) Place the obtained dry product in a low-temperature ultrafine pulverizer, and ultrafinely pulverize it to a D50 of about 5 microns at -20° C. to obtain Yunnan olive powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com