Pretreatment method of rubber ingredient production wastewater

A technology for the production of waste water and rubber additives, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of difficult treatment, low recycling rate of activated carbon, and high treatment cost. Achieve the effect of simple pretreatment method, conducive to energy saving and environmental protection, and obvious environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

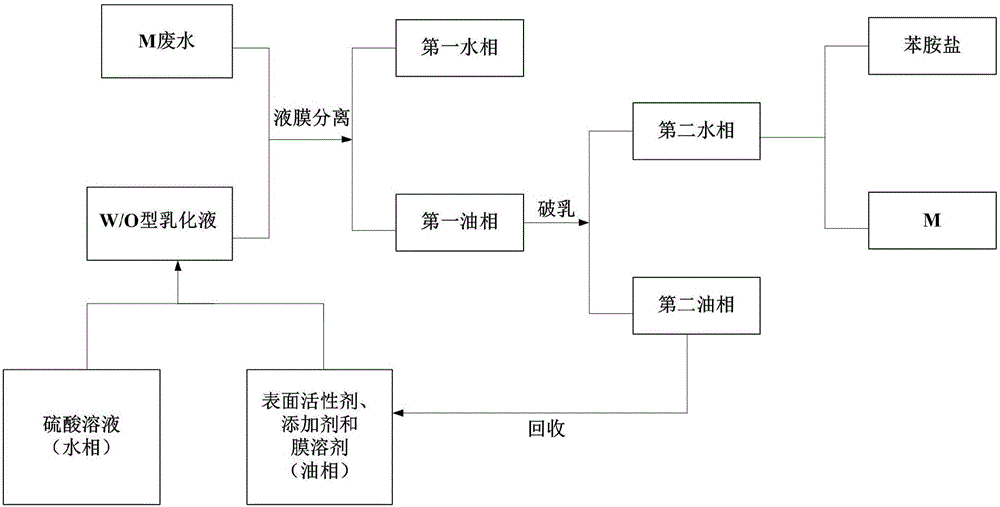

[0057] Using liquid membrane separation technology to pretreat M wastewater, including the following steps:

[0058] Take surfactant L-113A30L, additive liquid paraffin 60L and film solvent aviation kerosene 910L to form an oil phase, put it into an emulsifier, turn on the emulsifier, add 500L of sulfuric acid solution with a mass fraction of 10%, and shear at high speed for 10 minutes, that is A milky white water-in-oil emulsion was obtained. Take 200L of the emulsion and disperse it in 3000L of M wastewater, control the rotation speed at 150 rpm, stir and extract for 15 minutes, let it stand for stratification, and after the lower water phase is clarified, the water phase enters the biochemical treatment device; 205L of the extraction phase enters the electrostatic demulsification After 60 minutes of demulsification, the oil phase 130L was separated and reused for milk making; the water phase (recovery phase) 75L, which contained 12% aniline salt, could be reused in the prod...

Embodiment 2

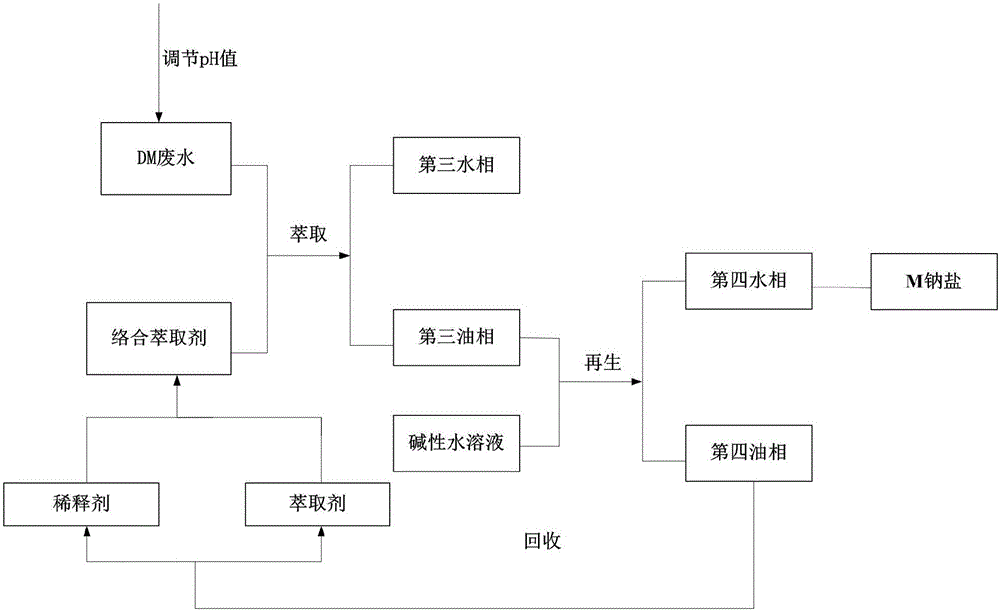

[0061] Pretreatment of DM wastewater by complex extraction technology includes the following steps:

[0062] Take 30L of N23530L and 70L of aviation kerosene to make a complex extraction agent, take 20L and disperse it into 520L of DM wastewater with pH=3, control the rotation speed at 150rpm, stir and extract for 30min, let it stand for stratification, and separate the oil-water two-phase after the lower water phase is clarified , to obtain 21 L of loaded oil phase, add 3 L of 15% sodium hydroxide solution, extract for 30 minutes, stand for stratification, separate 19.5 L of oil phase and 4.5 L of water phase, and reuse the oil phase for the treatment of DM wastewater.

[0063] After testing the treated wastewater, the COD was 1063mg / L, and the COD removal rate was 53.4%; the B / C value increased from 0.15 to 5.

Embodiment 3

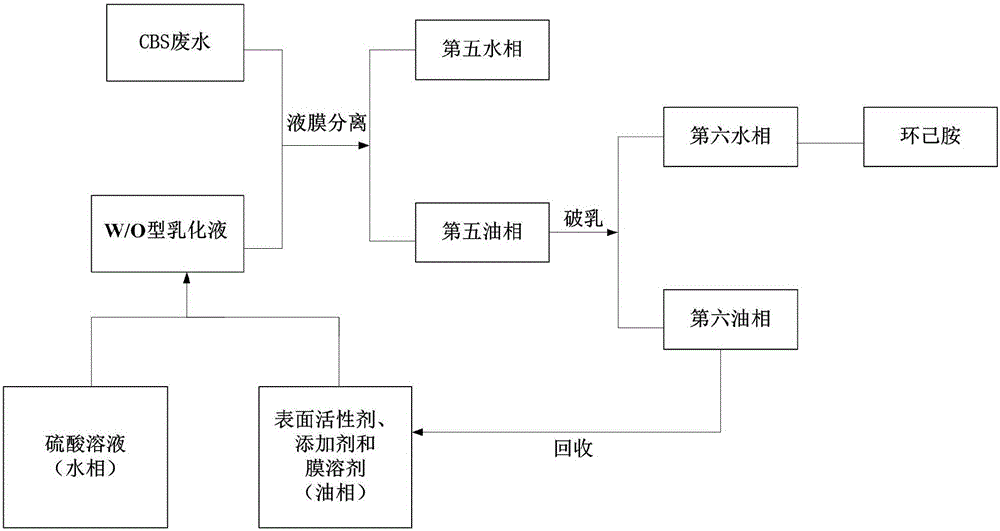

[0065] Using liquid membrane separation technology to pretreat CBS wastewater includes the following steps:

[0066] Take surfactant L-113A30L, additive liquid paraffin 60L and film solvent aviation kerosene 910L to form an oil phase, put it into an emulsifier, turn on the emulsifier, add 500L of sulfuric acid solution with a mass fraction of 10%, and shear at high speed for 10 minutes, that is A milky white water-in-oil emulsion was obtained. Take 600L of the emulsion and disperse it in 3000L of CBS wastewater with adjusted pH value, control the rotation speed at 150 rpm, stir and extract for 15 minutes, let it stand for stratification, and after the lower water phase is clarified, the water phase enters the biochemical treatment device; the extraction phase After 205L enters the electrostatic demulsifier for demulsification for 60 minutes, 400L of the oil phase is separated and reused for milk making; 75L of the water phase (recovery phase), which contains 6% cyclohexylamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com