Method for preparation of diphenyl carbonate by ester interchange

A technology of diphenyl carbonate and dimethyl carbonate, applied in the field of transesterification to prepare diphenyl carbonate, can solve the problems of easy deactivation, heterogeneous catalyst activity, low selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 9.0gSnCl 2 2H 2 O and 38.1gGa(NO 3 ) 3 Dissolve in 500mL water, add 300mL aqueous solution containing 29.3g anhydrous sodium carbonate to it, collect the obtained precipitate, wash with deionized water 3 times, each time 1000mL, and dry the obtained precipitate in an oven at 120°C for 24 hours , fired at 600°C for 5 hours to obtain SnO 2 / Ga 2 o 3 Mixed oxide catalyst MO-1, in which SnO and Ga 2 o 3 The parts by weight are respectively 30 parts and 70 parts.

Embodiment 2~15

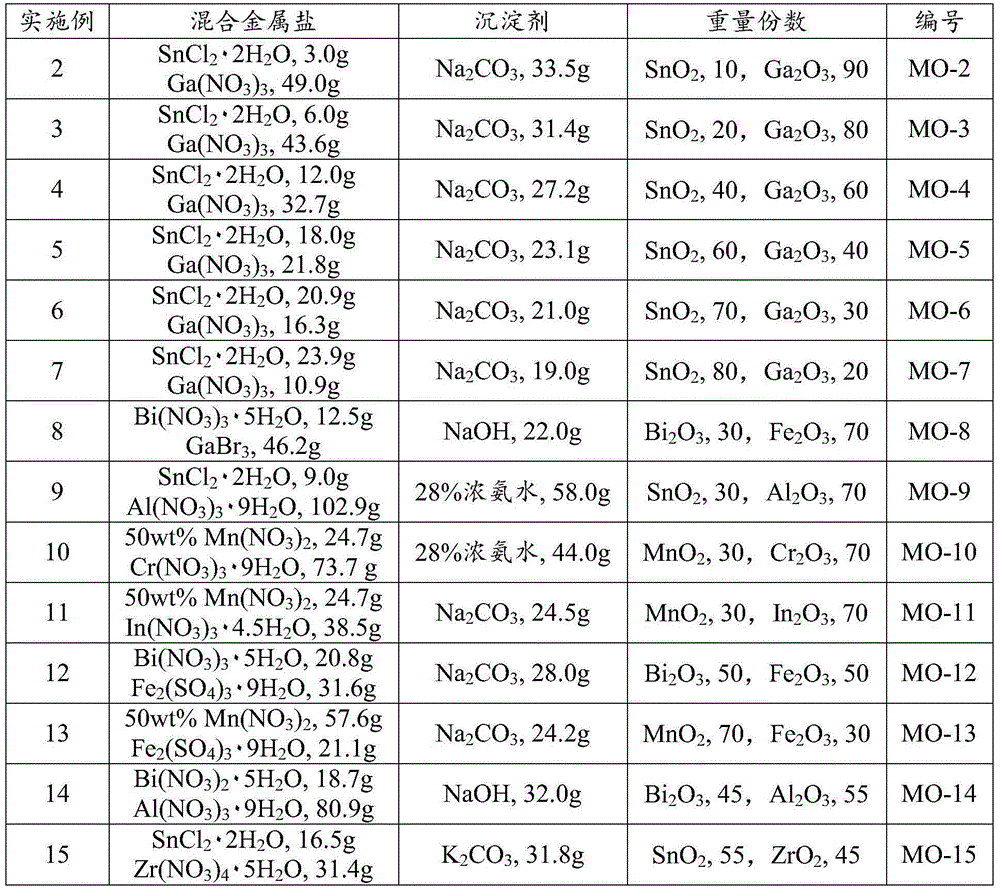

[0022] The mixed metal oxide catalyst obtained is shown in Table 1 by changing the type and amount of mixed metal salts and precipitants used, and keeping the rest of the conditions unchanged.

[0023] Table 1

[0024]

Embodiment 16

[0026] Take by weighing 10g of the MO-1 catalyst prepared by the above [Example 1] and place it in a 300mL stainless steel reactor, add N 2 Replace the air in the reactor, then fill with 50.0g phenyl acetate and 14.1g dimethyl carbonate, heat up to 175°C, react for 5 hours and then cool down, the reaction product is chromatographically analyzed to obtain the conversion of dimethyl carbonate (DMC) The yield was 87.9%, the selectivity of diphenyl carbonate (DPC) was 46.5%, and the selectivity of methylphenyl carbonate (MPC) was 52.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com