Flame-retardant polyol containing phosphorus linked pendant groups and preparation method of polyol

A technology of flame-retardant polyols and phosphorus-containing side groups, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems such as easy hydrolysis, material physical and chemical performance degradation, and fracture , to achieve the effect of easy adjustment of performance, easy control of process, and simple and easy control of process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

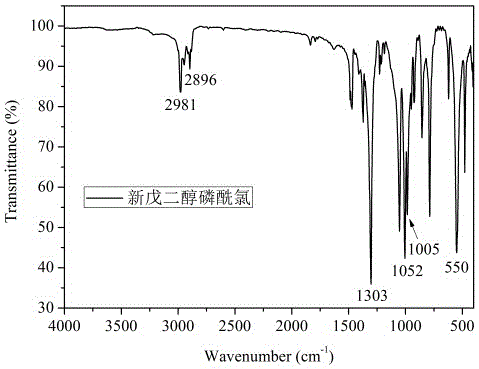

[0035] (1) Add 200ml of dichloromethane and 104.2g (1.0mol) of neopentyl glycol to a 500ml four-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel, a thermometer, and a nitrogen condensing reflux tube, stir and dissolve, Add 184.0 g (1.2 mol) of phosphorus oxychloride dropwise through a constant pressure dropping funnel for 2 hours. After the dropwise addition is completed, heat in an oil bath, slowly raise the temperature to 45°C and reflux for 6 hours to obtain a white solid, cool, filter, wash with deionized water, and vacuum-dry at 70°C to obtain a white powder intermediate neopentyl glycol phosphorus oxychloride ;

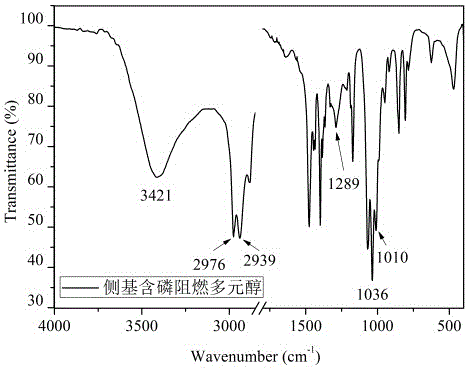

[0036] (2) Add 50ml of acetonitrile and 55.3g (0.6mol) of glycerol into a 500ml four-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel, a thermometer, and a condensing reflux tube, stir, dissolve, and add triethylamine 60.7g (0.6mol), 92.2g (0.5mol) intermediate neopentyl glycol phosphorus oxych...

Embodiment 2

[0038] (1) Add 150ml of chloroform and 104.2g (1.0mol) of neopentyl glycol to a 500ml four-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel, a thermometer, and a nitrogen condensing reflux tube, stir, dissolve, and pass through a constant Add 153.3g (1.0mol) phosphorus oxychloride dropwise to the pressure dropping funnel for 1 hour. After the dropwise addition is completed, heat in an oil bath, slowly raise the temperature to 65°C and reflux for 4 hours to obtain a white solid, cool, filter, wash with deionized water, and vacuum-dry at 80°C to obtain a white powder intermediate neopentyl glycol phosphorus oxychloride ;

[0039] (2) Add 50ml of N,N - dimethylformamide and 67.1g (0.5mol) 1,2,6 - Hexatriol, stir and dissolve, add 59.3g (0.75mol) of pyridine, add 100ml dropwise through the constant pressure dropping funnel N,N - 92.2 g (0.5 mol) of intermediate neopentyl glycol phosphorus oxychloride dissolved in dimethylformamide, added drop...

Embodiment 3

[0041] (1) Add 200ml of chloroform and 104.2g (1.0mol) of neopentyl glycol into a 500ml four-neck flask equipped with a mechanical stirrer, constant pressure dropping funnel, thermometer, and nitrogen condensing reflux tube, stir, dissolve, and Add 168.7g (1.1mol) phosphorus oxychloride dropwise to the pressure dropping funnel, and the dropping time is 1.5h. After the dropwise addition is completed, heat in an oil bath, slowly raise the temperature to 60°C and reflux for 5 hours to obtain a white solid, cool, filter, wash with deionized water, and vacuum-dry at 75°C to obtain a white powdery intermediate neopentyl glycol phosphorus oxychloride ;

[0042] (2) Add 80ml of N,N -Dimethylacetamide and 66.1g (0.55mol) of trimethylolethane, stir and dissolve, add 48.3g (0.66mol) of pyridine, add 100ml dropwise through a constant pressure dropping funnel N,N - 92.2 g (0.5 mol) of intermediate neopentyl glycol phosphorus oxychloride dissolved in dimethylacetamide, added dropwise fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com