Method for preparing powder material by polymer solvent removal

A technology of polymer powder and polymer, which is applied in the field of chemical production, can solve the problems of high production cost, large investment in equipment, high energy consumption, etc., and achieve the effects of quality improvement, wide range and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

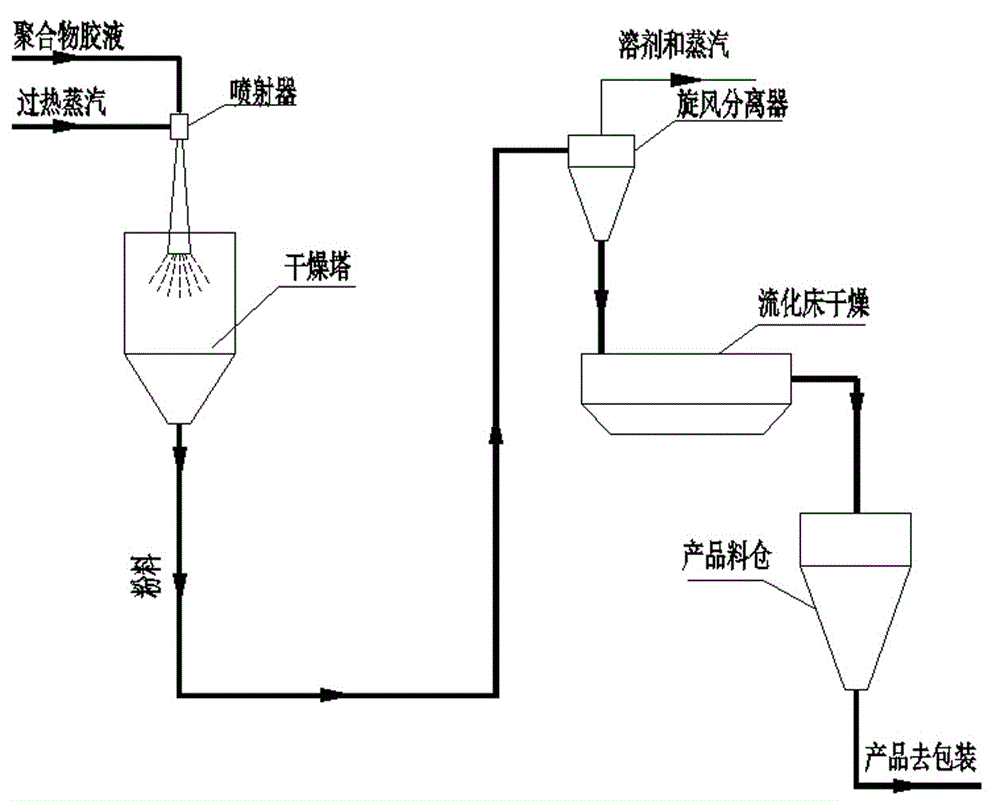

Image

Examples

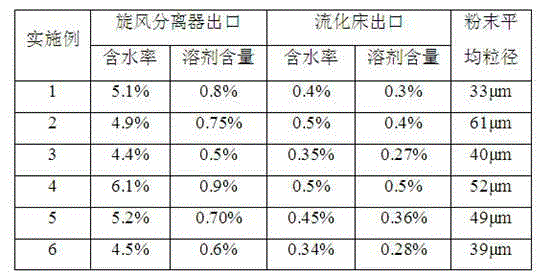

Embodiment 1

[0023] A kind of method that is used for polymer solvent removal and prepares powder, its step is:

[0024] (1) First, send 5wt% SEBS polymer glue and superheated steam with a pressure of 1.0MPa and a temperature of 180°C into the drying tower through an injector for spray drying to obtain polymer powder. The temperature in the drying tower is controlled at 140-190°C ; The polymer glue is a mixture of SEBS and n-hexane solvent;

[0025] (2) Then send the polymer powder into the cyclone separator to remove the organic solvent and water vapor. The temperature in the cyclone separator is controlled at 135-185°C, and the feed rate of the cyclone separator is controlled at 5-8m / s;

[0026] (3) Then send the polymer powder into a fluidized bed dryer for drying; the temperature of the fluidized bed is controlled at 80°C, and the fluidization time is 30 minutes.

[0027] (4) Finally, the polymer powder is sent to the product silo and then sent to the packaging machine for packaging...

Embodiment 2

[0029] A kind of method that is used for polymer solvent removal and prepares powder, its step is:

[0030] (1) First, send 40wt% SEBS polymer glue and superheated steam with a pressure of 2.5MPa and a temperature of 230°C into the drying tower through an injector for spray drying to obtain polymer powder. The temperature in the drying tower is controlled at 140-190°C ; The polymer glue is a mixture of SEBS and n-hexane solvent;

[0031] (2) Then send the polymer powder into the cyclone separator to remove the organic solvent and water vapor. The temperature in the cyclone separator is controlled at 135-185°C, and the feeding speed of the cyclone separator is controlled at 5-8m / s;

[0032] (3) Then send the polymer powder into a fluidized bed dryer for drying; the temperature of the fluidized bed is controlled at 150°C, and the fluidization time is 15 minutes.

[0033] (4) Finally, the polymer powder is sent to the product silo and then sent to the packaging machine for pac...

Embodiment 3

[0035] A kind of method that is used for polymer solvent removal and prepares powder, its step is:

[0036] (1) Firstly, 25wt% SEBS polymer glue and superheated steam with a pressure of 1.3MPa and a temperature of 200°C are sent into the drying tower through an injector for spray drying to obtain polymer powder, and the temperature in the drying tower is controlled at 140-190°C ; The polymer glue is a mixture of SEBS and n-hexane solvent;

[0037] (2) Then send the polymer powder into the cyclone separator to remove the organic solvent and water vapor. The temperature in the cyclone separator is controlled at 135-185°C, and the feeding speed of the cyclone separator is controlled at 5-8m / s;

[0038] (3) Then send the polymer powder into a fluidized bed dryer for drying; the temperature of the fluidized bed is controlled at 120°C, and the fluidization time is 25 minutes.

[0039] (4) Finally, the polymer powder is sent to the product silo and then sent to the packaging machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com