Inorganic pigment slurry processing method

A technology of inorganic pigments and processing methods, applied in the direction of pigment slurry, etc., can solve the problems of light calcium powder anti-coarseness, crystallization, uneven concentration of the upper and lower layers of the finished product, etc., and achieve the effect of bright color and not easy to crystallize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

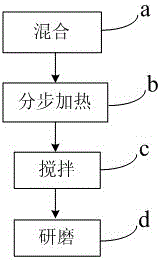

[0050] Include the following steps:

[0051] a. Mixing: Mix 20 parts of epoxy soybean oil, 0.5 part of high-polymerization polyvinyl chloride resin and dispersant, stir for 12 minutes at a speed of 1200 r / min, and then filter with a 200-mesh filter to obtain mixture H;

[0052] b. Step-by-step heating: Add 50 parts of epoxidized soybean oil, 0.5 parts of dioctyl terephthalate and dispersant into the mixing tank, heat to 50°C, and continue for 30 minutes, then pour the mixture H into the mixing tank , stirred at a speed of 1300r / min for 12min, then heated to 120°C, and then stood still for 12h to obtain a mixture R;

[0053]c. Stirring: Add the remaining epoxidized soybean oil, chlorinated normal alkanes, color enhancers, rheology modifiers, dispersants and dispersing aids into the mixture R, stir at a speed of 1800r / min for 5min, and then increase the speed of Adjust to 800r / min, add inorganic pigment and heavy calcium carbonate, then stir at 1600r / min for 15min to obtain pre...

Embodiment 2

[0056] Include the following steps:

[0057] a. Mixing: Mix 20 parts of epoxy soybean oil, 0.5 part of high-polymerization polyvinyl chloride resin and dispersant, stir for 20 minutes at a speed of 1500 r / min, and then filter with a 200-mesh filter to obtain the mixture H;

[0058] b. Step-by-step heating: Add 50 parts of epoxidized soybean oil, 0.5 parts of dioctyl terephthalate and dispersant into the mixing tank, heat to 60°C, and continue for 50 minutes, then pour the mixture H into the mixing tank , stirred at a speed of 1500r / min for 20min, then heated to 130°C, and then stood still for 15h to obtain a mixture R;

[0059] c. Stirring: Add the remaining epoxidized soybean oil, chlorinated normal alkanes, color enhancers, rheology modifiers, dispersants and dispersing aids into the mixture R, stir at a speed of 2000r / min for 10min, and then increase the speed of Adjust to 1000r / min, add inorganic pigment and heavy calcium carbonate, then stir at 2000r / min for 20min to obt...

Embodiment 3

[0062] Include the following steps:

[0063] a. Mixing: mix 20 parts of epoxidized soybean oil, 0.5 parts of high-polymerization polyvinyl chloride resin and dispersant, stir for 15 minutes at a speed of 1200-1500 r / min, and then filter with a 200-mesh filter to obtain the mixture H ;

[0064] b. Step-by-step heating: add 50 parts of epoxidized soybean oil, 0.5 parts of dioctyl terephthalate and dispersant into the mixing tank, heat it to 55°C and continue for 40 minutes, then pour the mixture H into the mixing tank , stirred at a speed of 1400r / min for 125min, then heated to 125°C, and then stood still for 13h to obtain a mixture R;

[0065] c. Stirring: Add the remaining epoxidized soybean oil, chlorinated normal alkanes, color enhancers, rheology modifiers, dispersants and dispersing aids into the mixture R, stir at a speed of 19000r / min for 6min, and then increase the speed of Adjust to 9000r / min, add inorganic pigment and heavy calcium carbonate, then stir at 1800r / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com