Liquid glue stopper for handling borehole wall collapsing

A wellbore collapse and liquid technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve problems such as poor tripping, easy leakage of chemical plugging agents, wellbore expansion, etc., to reduce the comprehensive Operating cost, avoiding serious leakage of plugging agent, and reducing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

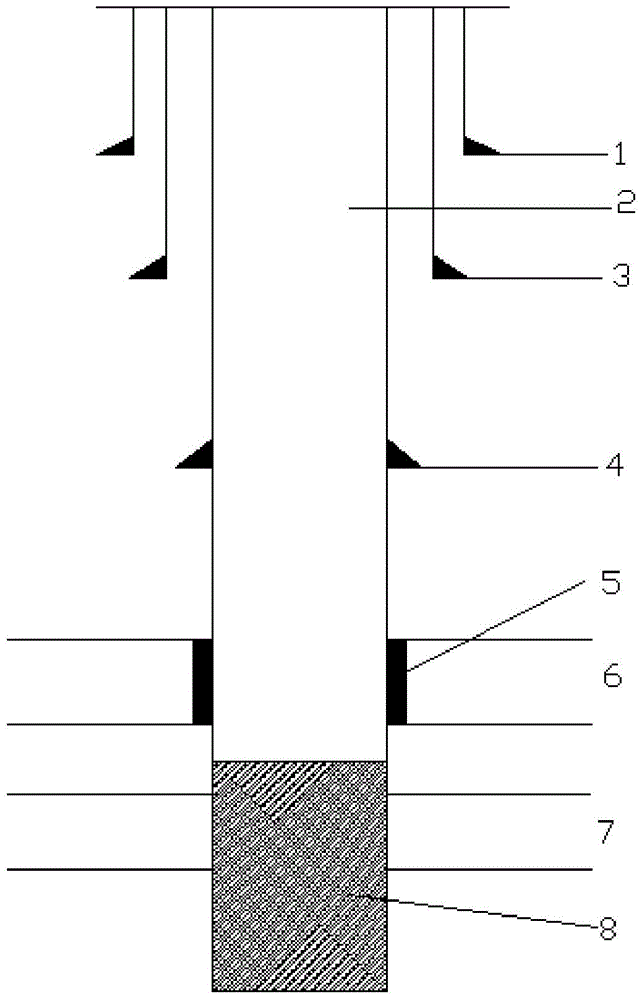

Image

Examples

Embodiment 1

[0031] Main ingredient A20g, including acrylamide 16g, butyl acetate 2g, isopropenyl acetate 2g

[0032] Activator B0.1g, including formaldehyde 0.07g, phenolic resin 0.03g

[0033] Weigh acrylamide, butyl acetate and isopropenyl acetate according to the above standards, and mix them to obtain main agent A; weigh formaldehyde and phenolic resin, and mix them to obtain activator B; add the obtained main agent A and activator B to 75ml of water in turn , stirred for 10 minutes, prepared into a uniform solution, and stirred after swelling for 10 minutes to obtain liquid rubber stopper sample 1#.

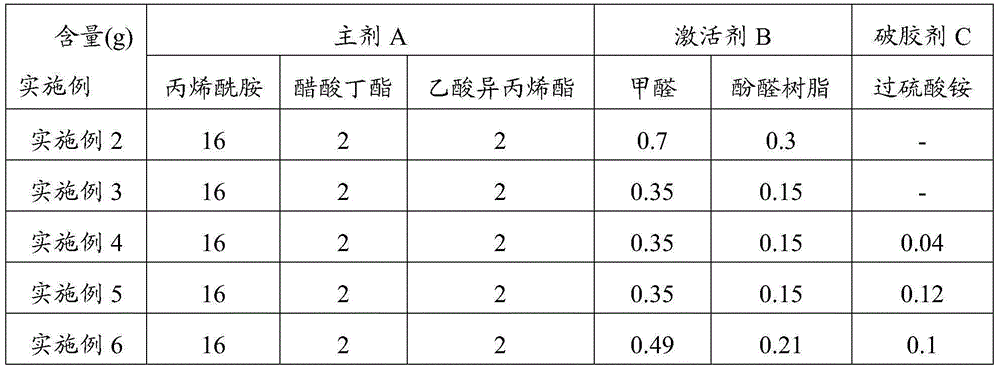

Embodiment 2~6

[0035] According to the content of each component shown in Table 1, the liquid rubber stopper samples 2# to 6# were respectively prepared according to the method described in Example 1.

[0036] Table 1

[0037]

Embodiment 7

[0038] Embodiment 7 measures the performance of liquid rubber stopper sample

[0039] Take 50ml of the liquid rubber stopper solutions obtained in Examples 1-6, add them into a vial (50ml) and seal them, put them into an oven at 150° C. to heat and cross-link and time them, and observe the cross-linking situation every 10 minutes. When the sample thickens rapidly, use a HAKKERS150 high temperature rheometer every 10 minutes at a shear rate of 1.5s -1 Measure the strength of the sample. The time when the sample strength reaches the maximum pressure difference of 40MPa is the crosslinking time.

[0040] After the sample strength reaches the maximum pressure difference of 40MPa, observe the gel-breaking situation of the samples in Examples 4-6 every day. When the samples are completely in solution, the gel-breaking is completed, and the time used is the self-gel-breaking time.

[0041] Table 2 shows the measurement results of crosslinking time, withstand pressure difference and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com