A kind of gas well high temperature resistant recyclable clean fracturing fluid

A technology of clean fracturing fluid and high temperature resistance, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor high temperature resistance and inability to recycle and reuse, so as to reduce the cost of fracturing construction and ensure green Environmental protection production, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

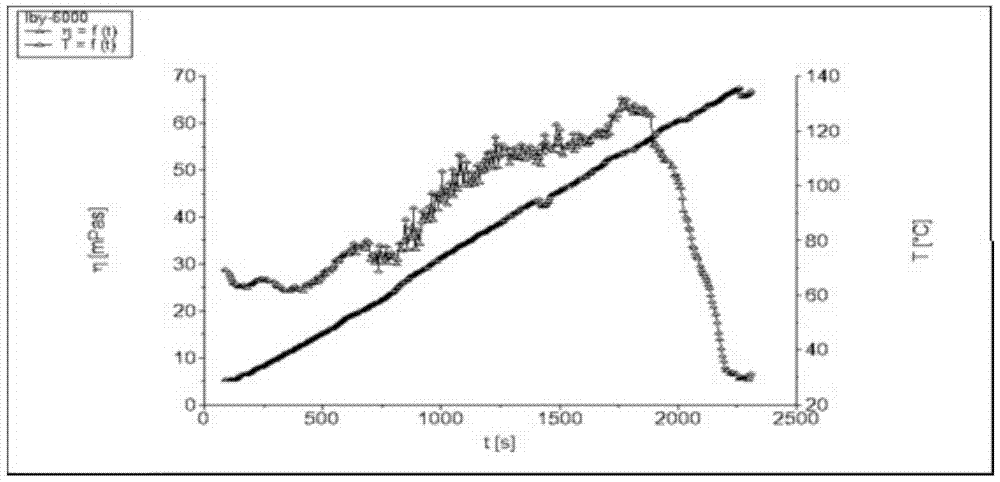

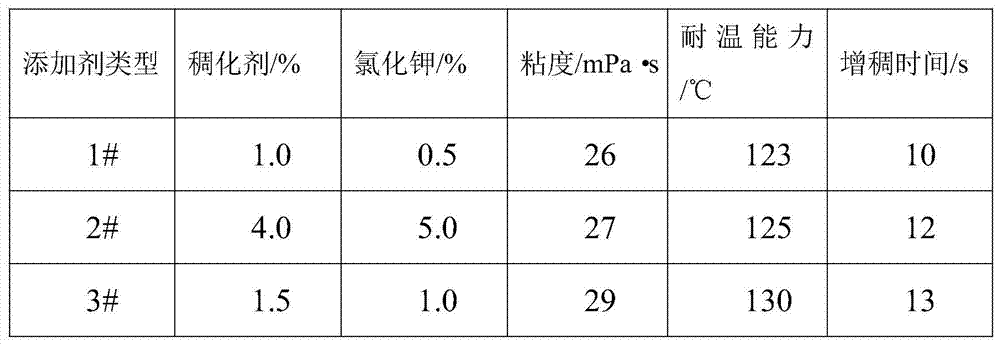

Embodiment 1

[0034] A gas well high temperature resistant recyclable clean fracturing fluid, the raw materials used in the fracturing fluid and the weight percentages of each component are as follows:

[0035] Thickener, 1%;

[0036] Potassium chloride, 0.5%;

[0037] Water, 98.5%.

[0038] Described thickening agent is made up of the raw material of following mass ratio:

[0039] 35%, 3-trimeric epoxyhexafluoropropane amidopropyl betaine;

[0040] 10%, coconut oil fatty acid diethanolamine;

[0041] 1%, co-solvent;

[0042] 54%, water.

[0043] The co-solvent is a mixture of methanol and isopropanol, and the mass ratio of methanol to isopropanol is 1:3.

[0044] In this example, the high temperature-resistant recyclable clean fracturing fluid of the gas well has a thickening time of less than 20s, and the viscosity is at least 25mPa·s at normal ground temperature (25°C), and the viscosity is ≤5mPa when the formation temperature is greater than 130°C s; high temperature resistant re...

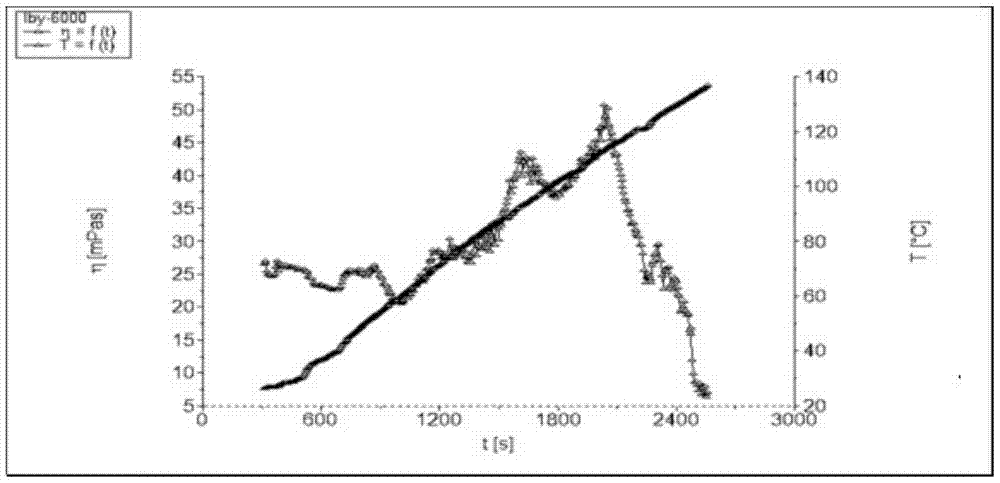

Embodiment 2

[0046] A gas well high temperature resistant recyclable clean fracturing fluid, the raw materials used in the fracturing fluid and the weight percentages of each component are as follows:

[0047] Thickener, 4%;

[0048] Potassium chloride, 5%;

[0049] Water, 91%.

[0050] Described thickening agent is made up of the raw material of following mass ratio:

[0051] 55%, 3-trimeric epoxyhexafluoropropane amidopropyl betaine;

[0052] 25%, coconut oil fatty acid diethanolamine;

[0053] 5%, co-solvent;

[0054] 15%, water.

[0055] The cosolvent is a mixture of methanol and isopropanol, and the mass ratio of methanol to isopropanol is 1:5.

[0056] In this example, the high temperature-resistant recyclable clean fracturing fluid of the gas well has a thickening time of less than 20s, and the viscosity is at least 25mPa·s at normal ground temperature (25°C), and the viscosity is ≤5mPa when the formation temperature is greater than 130°C s; high temperature resistant recycla...

Embodiment 3

[0058] A gas well high temperature resistant recyclable clean fracturing fluid, the raw materials used in the fracturing fluid and the weight percentages of each component are as follows:

[0059] Thickener, 1.5%;

[0060] Potassium chloride, 1.0%;

[0061] Water, 97.5%.

[0062] Described thickening agent is made up of the raw material of following mass ratio:

[0063] 40%, 3-trimeric epoxyhexafluoropropane amidopropyl betaine;

[0064]14%, coconut oil fatty acid amide;

[0065] 3%, co-solvent;

[0066] 43%, water.

[0067] The cosolvent is a mixture of methanol and isopropanol, and the mass ratio of methanol to isopropanol is 1:10.

[0068] In this example, the high temperature-resistant recyclable clean fracturing fluid of the gas well has a thickening time of less than 20s, and the viscosity is at least 25mPa·s at normal ground temperature (25°C), and the viscosity is ≤5mPa when the formation temperature is greater than 130°C s; high temperature resistant recyclable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com