Phase-change type vanadium oxide material and preparing method thereof

A vanadium oxide and phase change technology, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problem that the regional phase change temperature adjustment of materials cannot be realized, and the phase change temperature adjustment process is complicated and cannot be realized. Continuous adjustment and other problems, to achieve the effect of large phase change temperature adjustment range, easy operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a method for preparing a phase-change vanadium oxide material, comprising the following steps:

[0037] A vanadium oxide substrate is provided, and gas ion implantation is performed on the vanadium oxide substrate to obtain a phase-change vanadium oxide material with a preset phase transition temperature.

[0038] Specifically, the vanadium oxide substrate may be in the form of a thin film, or in the form of a patterned nanostructure, a block, or the like. The material of the vanadium oxide substrate can be VO 2 , can also be other low-valent oxides of vanadium VO, V 2 o 3 or V 2 o 5 , which all have semiconductor-metal phase transition characteristics.

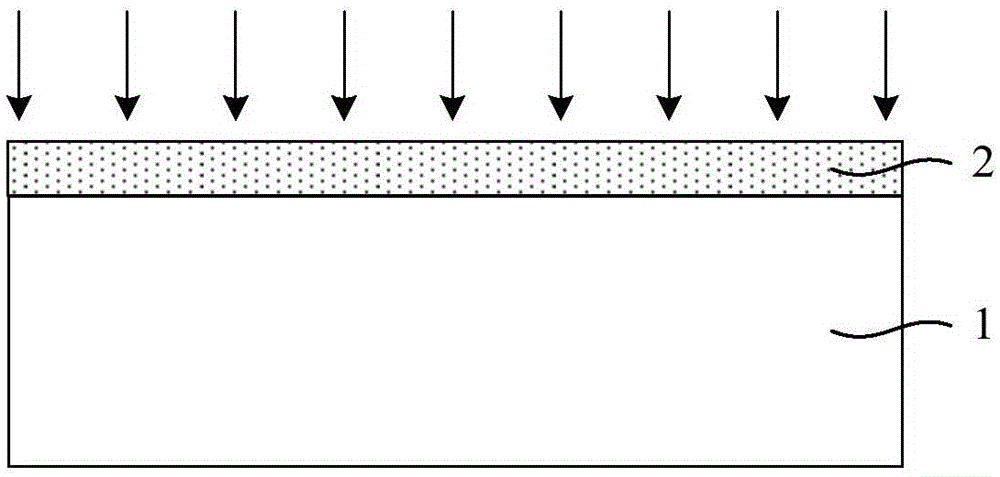

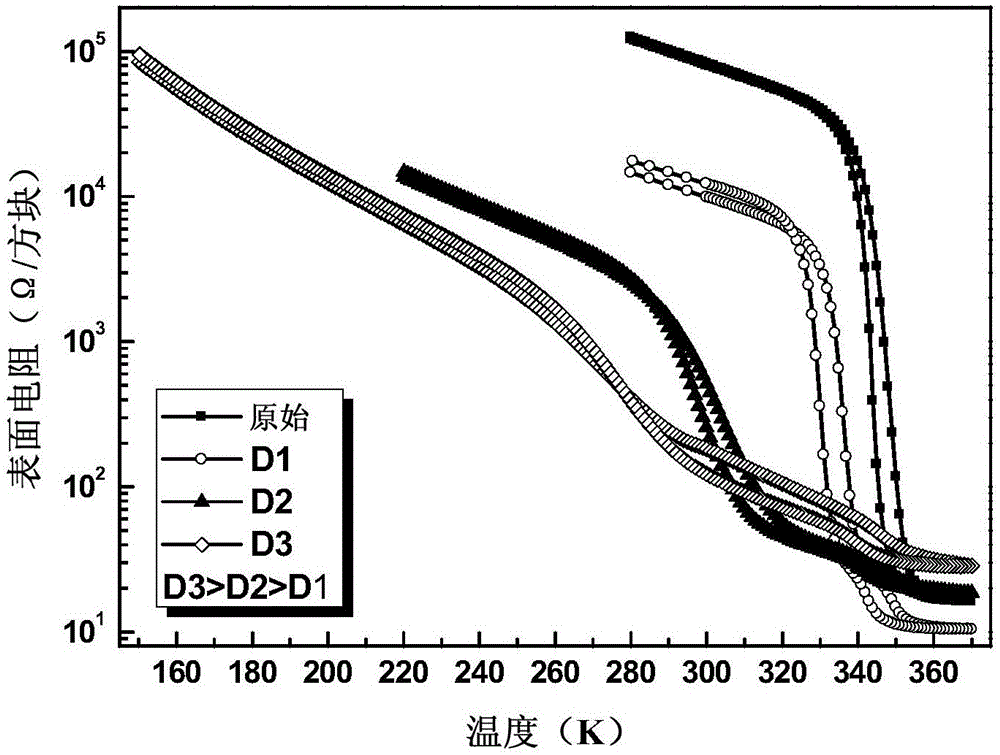

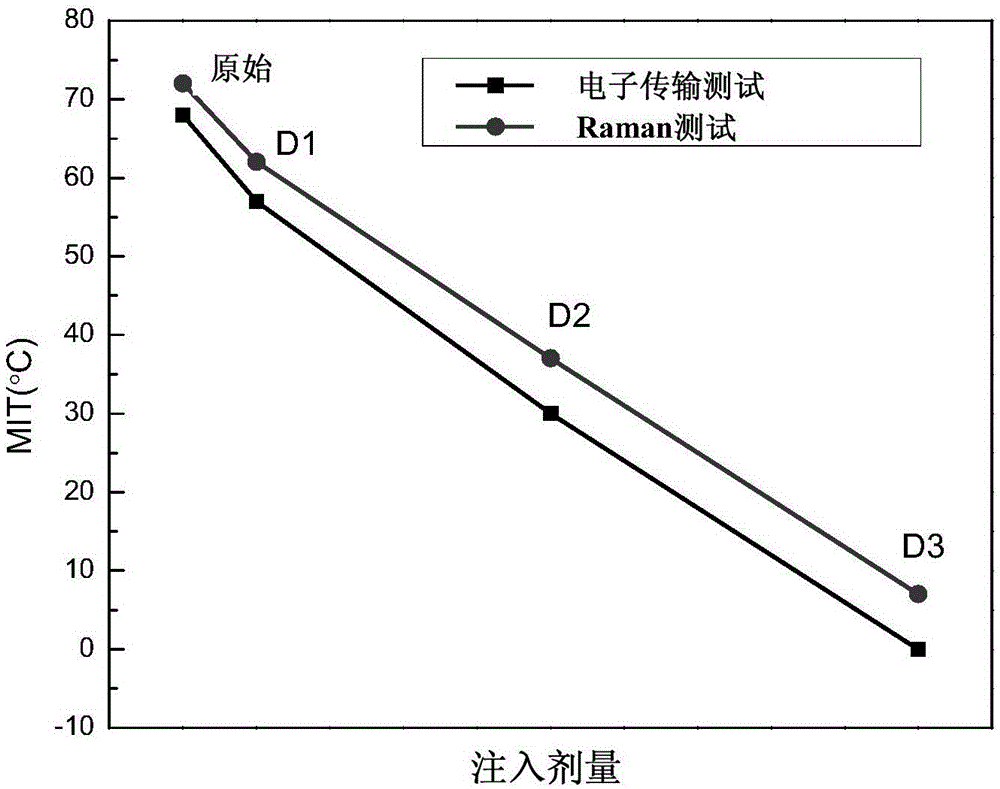

[0039] As an example, a vanadium dioxide film is used as the vanadium oxide substrate. like figure 1 As shown, first a vanadium dioxide film 2 is prepared on a substrate 1, and then gas ion implantation is performed on the vanadium dioxide film 2. The preparation method of the vanadium di...

Embodiment 2

[0053] This embodiment adopts basically the same technical scheme as that of Embodiment 1, the difference is that in Embodiment 1, the overall phase transition temperature of the vanadium oxide substrate is changed, while in this embodiment, only the phase transition temperature of a local region of the vanadium oxide substrate is changed. phase transition temperature.

[0054] like Figure 4 As shown, a vanadium dioxide film 2 is first prepared on a substrate 1, and then gas ion implantation is performed on the vanadium dioxide film 2, wherein, when performing gas ion implantation, a mask plate 3 is used, and the mask plate 3. Only a part of the vanadium dioxide thin film 2 is exposed, so that gas ions are only implanted into the exposed area, so as to change the phase transition temperature of the vanadium oxide substrate in a local area. This phase-change vanadium oxide material with local phase transition temperature changes has good application prospects in the preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com