Treatment technology for oily sludge and drillings

A technology of oily sludge and drilling cuttings, applied in the field of pollution control, can solve the problems of increased operating costs, etc., and achieve the effects of strong practicability, high practical application value, and energy saving

Inactive Publication Date: 2015-11-25

成都西石大油田技术服务有限公司

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this method has a simple process and meets environmental protection and various industrial requirements, the preparation of the flushing liquid in the treatment process requires heating the flushing liquid to 80°C, which increases the operating cost and is not conducive to large-scale industrial operation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0036] First prepare oily sludge and drilling cuttings cleaning solution, accurately weigh sodium carbonate and dodecyltrimethylammonium chloride, dissolve them in water, and mix them evenly according to the concentration ratio of 2:1, that is, sodium carbonate: 8g / L, ten Dialkyltrimethylammonium chloride: 4g / L; then add reverse demulsifier 2.5% (volume ratio), PAM7500mg / L, PAC625mg / L, fully stir, mix evenly and then set aside.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

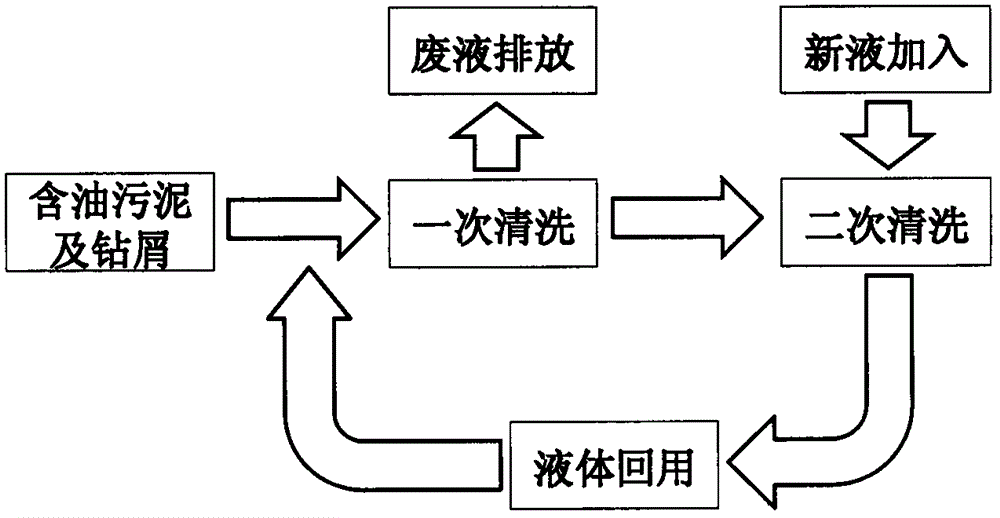

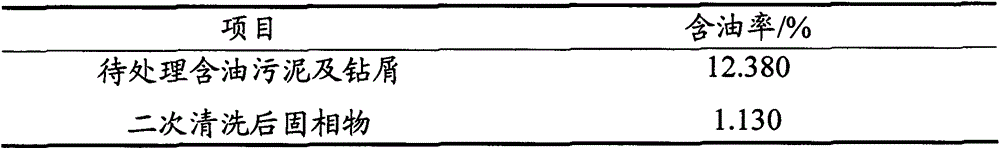

The invention discloses a treatment technology for oily sludge and drillings. The technology of combination of two times of rinsing is provided according to the characteristics of pollutants in the oily sludge and drillings, so that the problem that the oily sludge and drillings are not treated thoroughly during a single-cleaning process is avoided. Preparation of a cleaning solution for the treatment technology is characterized by comprising the following steps: sodium carbonate and dodecyl trimethyl ammonium chloride are accurately weighed, are dissolved in water, and are mixed uniformly according to a concentration ratio of 2 to 1; then a reverse demulsifier with the volume ratio of 2.5%, PAM with the concentration of 7500 mg / L and PAC with the concentration of 625 mg / L are added in; and the mixture is fully stirred and is mixed uniformly. According to the treatment technology disclosed by the invention, a current treatment technology for the oily sludge and drillings in China is successfully improved; the pollutants in the oily sludge and drillings are subjected to stabilization and detoxification treatment by adopting a chemical method; and the combination of two times of rinsing is innovatively provided, so that energy consumption is further reduced, and the secondary cleaning solution can be recycled for use. Compared with the current technology in China, the treatment technology disclosed by the invention has the advantages that the technology is simple in treatment process and high in practicality, and is capable of being widely applied. Therefore, the treatment technology has novelty, creativity and advancement and has very high practical application value.

Description

technical field [0001] The invention relates to pollution control in the drilling process of oil and gas fields, in particular to oily sludge and drill cuttings treatment technology. Background technique [0002] Oily sludge and drill cuttings are solid pollutants produced during oil well exploitation. It is a complex multiphase system containing a large amount of oils, phenols, heavy metals, various polymers, defoamers, emulsifiers, etc. If it is discharged without treatment, it will cause adverse effects on the environment. Its leachate has high toxicity. Oilfield drilling produces a large amount of oily sludge and cuttings every day. The direct discharge of oily sludge and cuttings will affect the nutritional environment and quality of crop growth. Long-term accumulation will cause serious damage to surface vegetation and pollute the soil. and water sources, endangering human survival. Therefore, the treatment of oily sludge and drilling cuttings from oilfield drilling...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B41/00E21B21/06E21B21/01C09K8/524G01N21/3577G01N21/3563

Inventor 罗顺祥卢耀平李赵张姝琳张洪铭

Owner 成都西石大油田技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com