Water content testing instrument for thermal horizontal well

A technology for horizontal wells and water content, which is used in the measurement, production of fluids, and earth-moving drilling, etc. It can solve the problems of zero-point drift, anti-interference, low test accuracy, and inability to solve the influence of various flow patterns, so as to achieve reliable and safe testing and construction. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

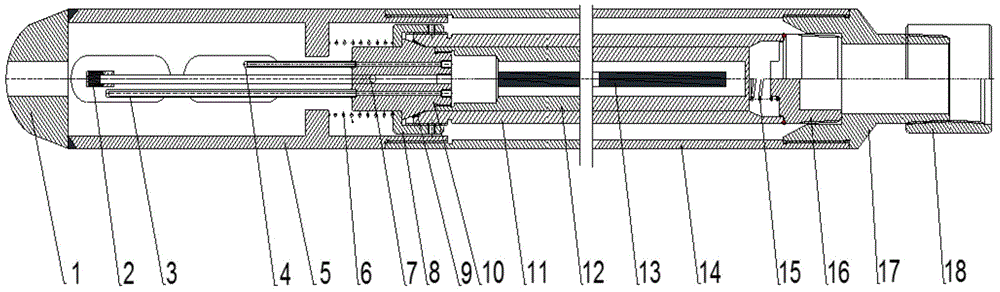

[0021] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0022] As shown in Figure 1, the thermal recovery horizontal well water content tester comprises interconnected sensors and a data acquisition circuit 13, and the data acquisition circuit is protected in a metal thermos bottle 12, and the metal thermos bottle is at the front port of itself A sensor body seat 10 for connecting and fixing the sensor is provided, and the sensor includes a water-containing sensor 2 , a differential temperature sensor head, and a pressure sensor probe 7 . The outside of the metal thermos bottle is covered with an instrument inner protection cylinder 11, and the outside of the instrument inner protection cylinder is covered with an instrument outer protection cylinder 14. An annular space i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com