Underground station constructed by prefabricated parts and construction method thereof

A technology of prefabricated components and underground stations, applied in infrastructure engineering, buildings, artificial islands, etc., can solve problems such as slowing down construction speed, reducing construction efficiency, longitudinal reinforcement deviation, etc., to reduce the impact of noise and vibration, soil Effect of small disturbance and flexible construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

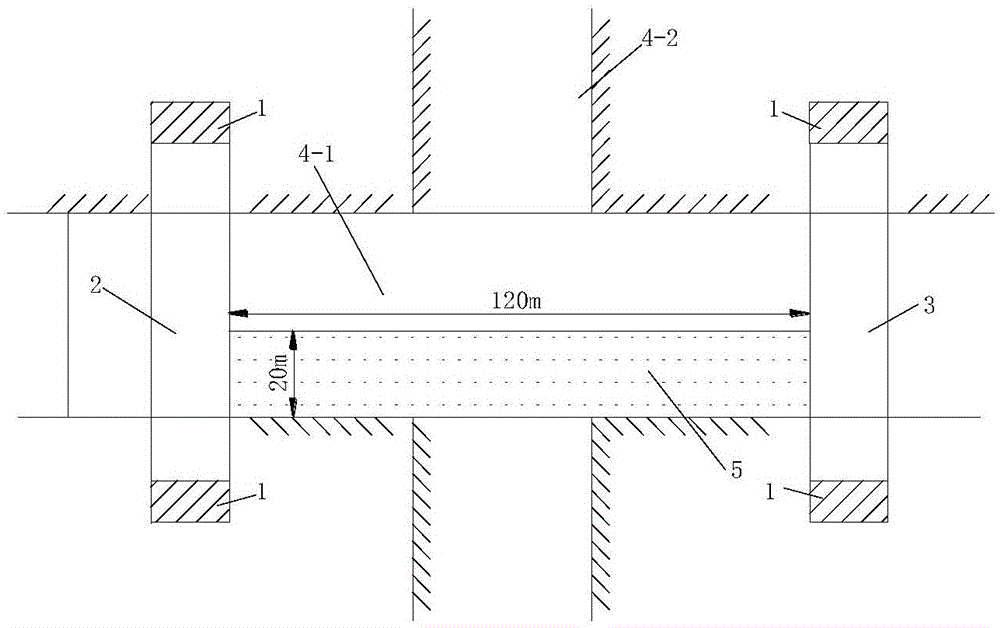

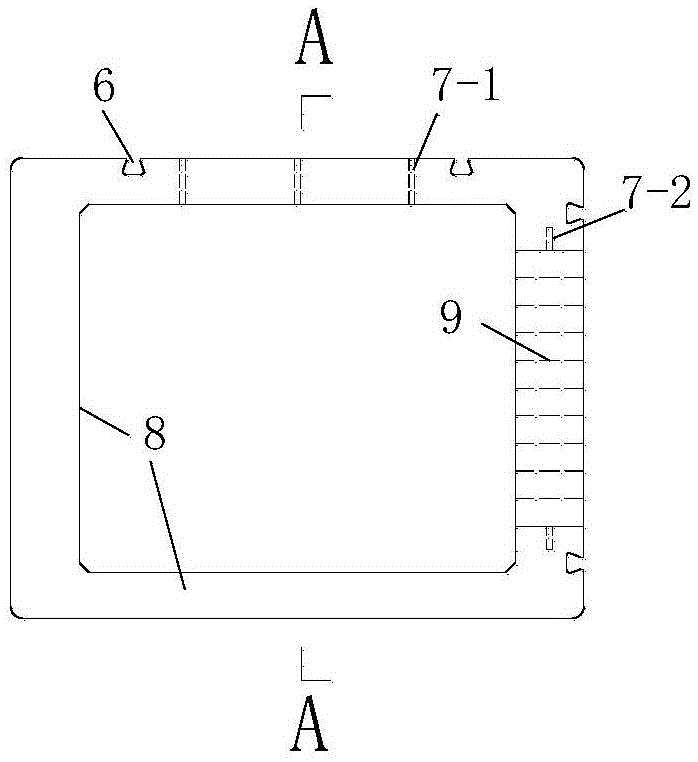

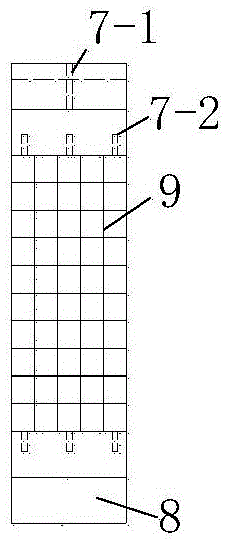

[0053] Such as figure 1 As shown, the underground station 5 is arranged on the side of the road 4-1 at the construction site of the underground station, and the other road 4-2 at the intersection is not arranged. First, the shaft 1 is constructed on both sides of the road at the two ends of the station, and the construction is completed. After the vertical shaft 1, the construction of the starting tunnel 2 and the receiving tunnel 3 is carried out. After the completion of the two constructions, a strip track is laid along the axial direction of the tunnel in the starting tunnel 2 and the receiving tunnel 3 (the strip track refers to the tunnel from the shaft to the construction section). The laid track is used to transport prefabricated components in the early stage), and the rectangular pipe-jacking strip track is laid along the axis of the station at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com