Unsealing method for flip-chip packaging device

A technology for packaging devices and flip-chips, which is applied in the field of semiconductor integrated circuit testing, can solve the problems of unsealing of sealed devices, failure of unsealing, insufficient grinding, etc., and achieves difficult to control etching accuracy, poor adaptability, and guarantees the quality of unsealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

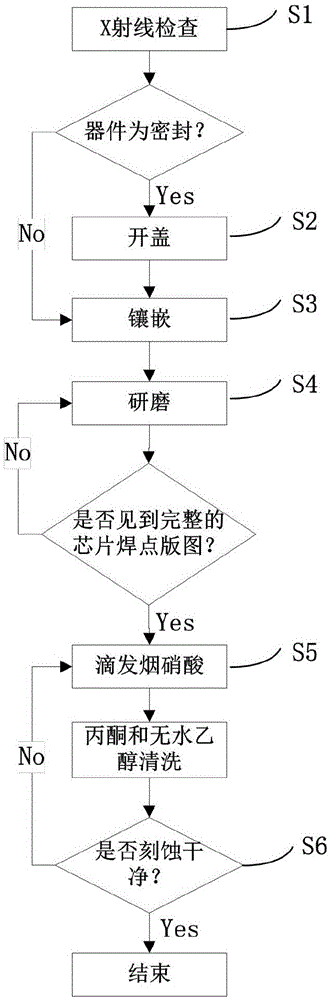

[0033] like figure 1 As shown, the present invention provides a method for unsealing a flip-chip packaged device, comprising the steps of:

[0034] S1), inspect the device in the Y-axis and X-axis, and obtain clear X-ray photos of the device in two directions. The Y-axis inspection is to obtain the chip solder joint layout photos of the device to prepare for grinding; the X-axis inspection is mainly to determine the structure of the device in the vertical direction and the thickness of the substrate material to ensure that the quality of the grinding process is controllable.

[0035] S2), open the sealed device (this step is only for sealed devices)

[0036] If the device is a sealed type, the sealing cover of the device must be opened first. The sealing cover is mostly bonded to the substrate by metal and ceramic. The metal sealing cap can be opened with a sharp knife; the ceramic sealing cap can be opened with a pliers-type capping machine. The purpose of opening the cov...

Embodiment 2

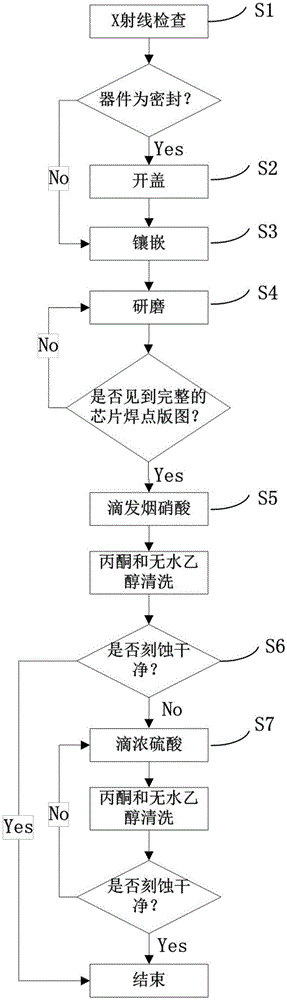

[0048] like figure 2 As shown, the present invention provides a method for unsealing a flip-chip packaged device, comprising the following steps:

[0049] S1), X-ray inspection is performed on the device, and X-ray photos of the device are obtained; preferably, X-ray inspections are performed on the device in the X-axis and Y-axis respectively, and X-ray photos in two directions of the device are obtained.

[0050] S3), perform device embedding; preferably, in this step, place the device substrate horizontally in the embedding equipment facing downward. In order to prevent the device from moving and turning over during the mounting process, a small amount of double-sided adhesive tape was pasted on the sample stage of the mounting equipment to fix the device. When potting powder or mounting liquid, it should be added slowly to prevent the device from being washed away. Since the hot mounting process will generate high temperature and high pressure, in order to prevent chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com