Automatic liquid volume quantifying and concentrating method with adjustable precision

A liquid volume and automatic technology, which is applied in the field of liquid volume quantification and concentration in chemical pretreatment, can solve the problems of limited scale (cannot be arbitrarily fixed to a certain volume, concentrated or single volume quantification, difficult to meet the measurement, etc.) Human error and labor intensity, wide user selectivity, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

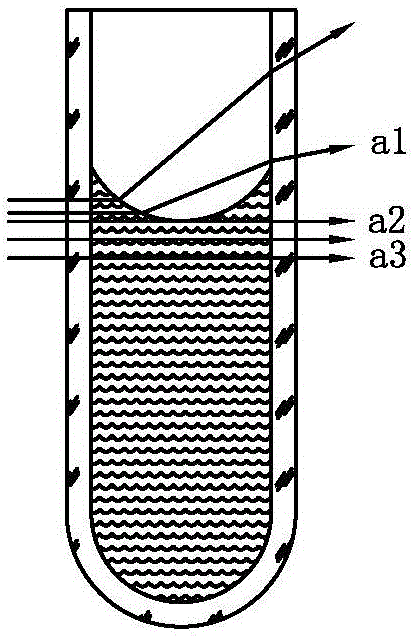

[0055] figure 1 Among them, the existing concave liquid surface detection method uses the refraction principle of light to judge the position of the liquid surface; when the light emitted by the light source at the transmitting end does not pass through the critical position of the horizontal tangent line of the concave liquid surface, the light passes through vertically and directly shines on the receiving end When the light emitted by the light source at the transmitting end exceeds the critical position of the horizontal tangent of the concave liquid surface, the light will be refracted, and the receiving end will not receive the light. At this time It is called the refracted ray a1; or the received light intensity drops significantly, so that it is judged that this position is exactly the position of the meniscus, at this time it is called the critical ray a2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com