Method for preparing electrophoretic particles, electrophoretic particles, electrophoretic dispersion, electrophoretic sheet, electrophoretic apparatus, and electronic device

An electrophoretic particle and manufacturing method technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as AMP particle agglutination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0145] A first embodiment of the method for producing an electrophoretic particle of the present invention will be described.

[0146] First, before describing the method of manufacturing the electrophoretic particle of the present embodiment, the electrophoretic particle (electrophoretic particle of the present embodiment) manufactured by applying the method of manufacturing the electrophoretic particle of the present embodiment will be described.

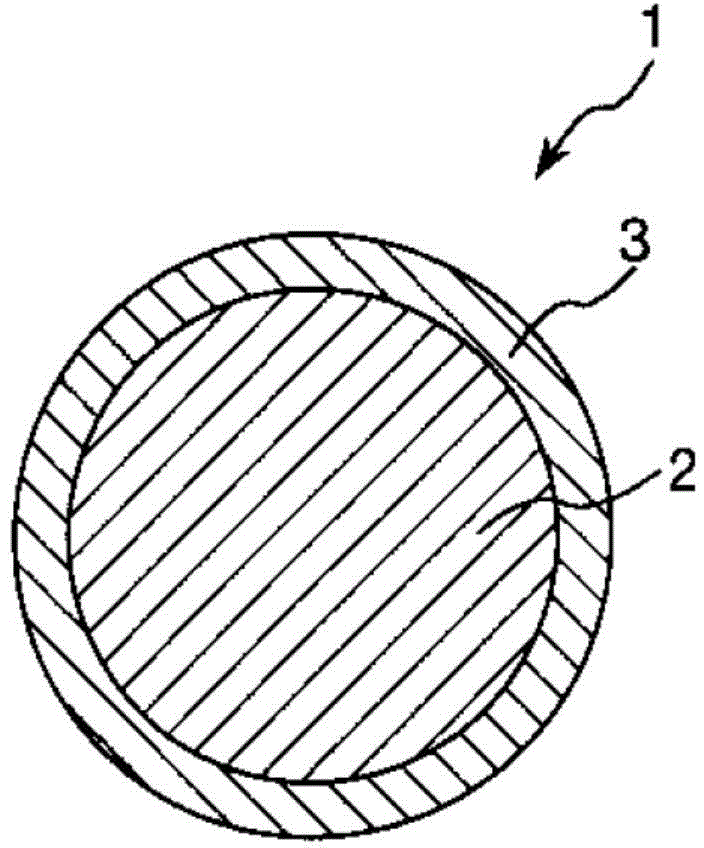

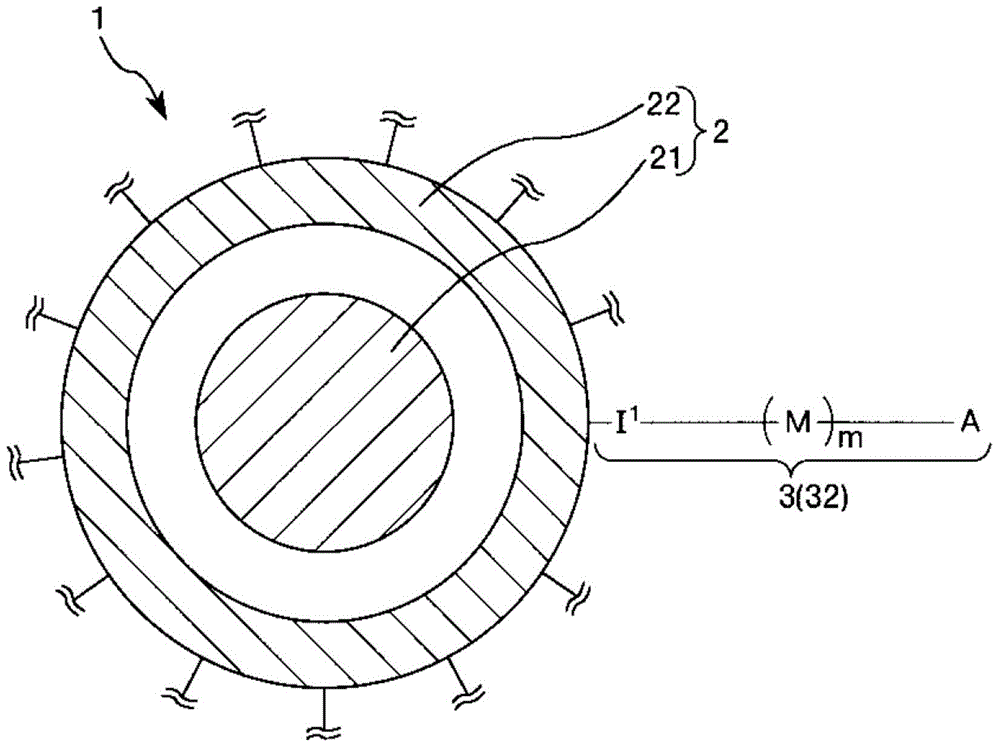

[0147] The electrophoretic particle produced by using the method for producing an electrophoretic particle according to this embodiment has the particle and a coating layer covering at least a part of the particle. The particle includes a mother particle and a shell made of an organic polymer and enclosing the mother particle in a cellular form. In addition, the coating layer has a polymer obtained by polymerizing a monomer from a polymerization initiating group as an origin. An electrophoretic particle having such a configuratio...

no. 2 Embodiment approach

[0402] Next, a second embodiment of the method for producing electrophoretic particles of the present invention will be described.

[0403] First, before describing the method of manufacturing the electrophoretic particle of the present embodiment, the electrophoretic particle (electrophoretic particle of the present embodiment) manufactured by applying the method of manufacturing the electrophoretic particle of the present embodiment will be described.

[0404] The electrophoretic particle produced by applying the method for producing an electrophoretic particle according to this embodiment has the particle and a coating layer covering at least a part of the particle, similarly to the electrophoretic particle 1 of the first embodiment described above. The particle includes a mother particle and a shell made of an organic polymer and enclosing the mother particle in a cellular form. In addition, the covering layer contains a compound (second compound) having a functional group r...

Embodiment 1

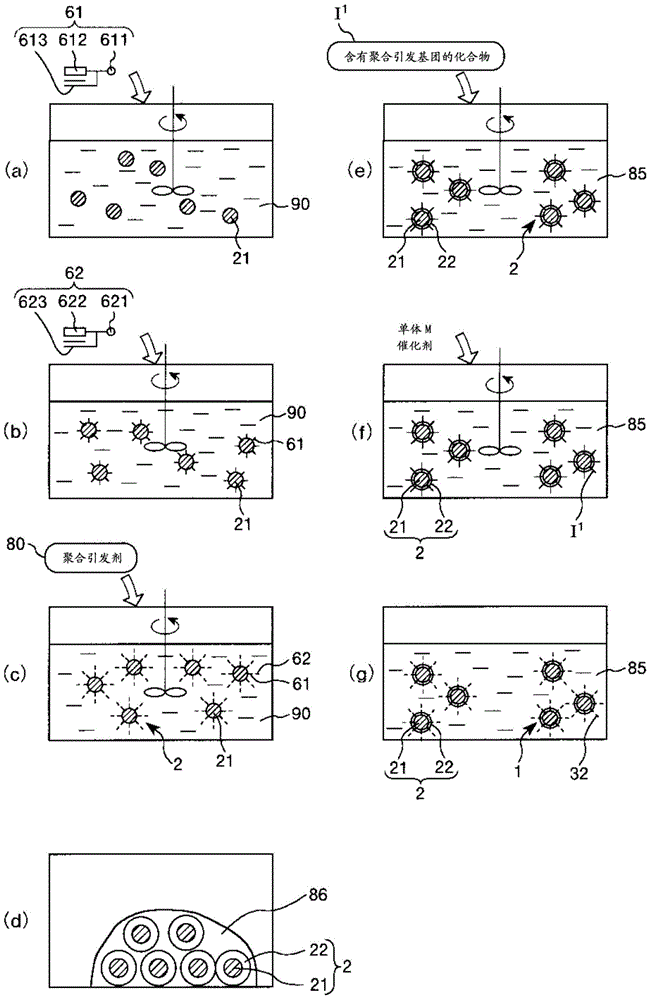

[0649] [1] First, carbon black particles with an average particle diameter of 0.1 μm (master particle: manufactured by Asahi Carbon Co., Ltd., “Asahi Salmal”) were dispersed in water (aqueous dispersion liquid) to obtain a dispersion liquid. In addition, the surface of carbon black particles is negatively charged.

[0650] [2] Next, a cationic polymerizable surfactant (first polymerizable surfactant: DMC) is added to the dispersion liquid. Then, the dispersion liquid was stirred while being irradiated with ultrasonic waves to obtain a mixed liquid.

[0651][3] Next, in this mixed solution, a polymerizable surfactant having a hydroxyl group (the second polymerizable surfactant: ADEKA product, Adecaria software ER-10) is mixed with a cationic polymerizable surfactant Add in equimolar amounts. Then, this liquid mixture was stirred while irradiating ultrasonic waves to obtain an emulsion.

[0652] [4] Next, sodium persulfate (polymerization initiator) was added to the emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com