Manufacturing method of silicon wafer and silicon wafer

A manufacturing method and technology for silicon wafers, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of reduced haze level and insufficient haze level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0079] In addition, the present invention is not limited to the above-described embodiments, and various improvements, design changes, and the like can be made without departing from the gist of the present invention.

[0080] In the above-mentioned embodiment, the case where at least hydrogen fluoride cleaning is performed in the cleaning step has been described. However, in addition to the above-mentioned hydrogen fluoride cleaning, it is also possible to perform brush cleaning in which the brush is brought into sliding contact with the front surface of the wafer to remove dirt on the front surface of the wafer. The element that becomes the hydrogen termination on the front side of the wafer. By using the scrub together, the hydrogen termination rate on the front side of the wafer can be increased more efficiently. In addition, it is preferable that this scrubbing is performed before hydrogen fluoride cleaning.

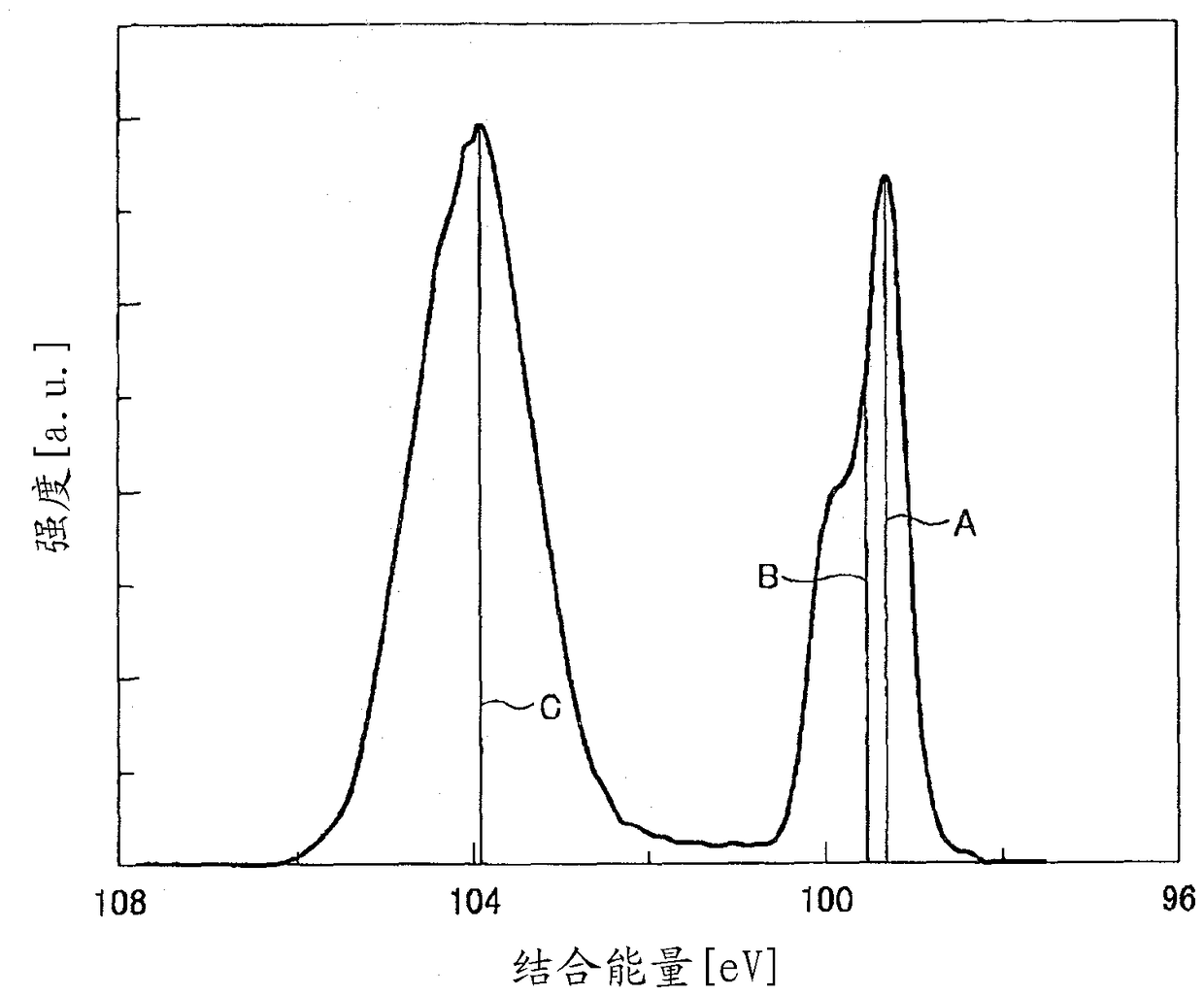

[0081] In addition, in the calculation of the hydrogen termin...

Embodiment 1

[0086] A silicon wafer having a diameter of 300 mm having undergone the rough grinding process was prepared. With respect to the prepared silicon wafer, the conditions were changed as follows, and the finish polishing process was implemented, and then, the cleaning process was implemented with respect to the silicon wafer which completed the finish grinding process.

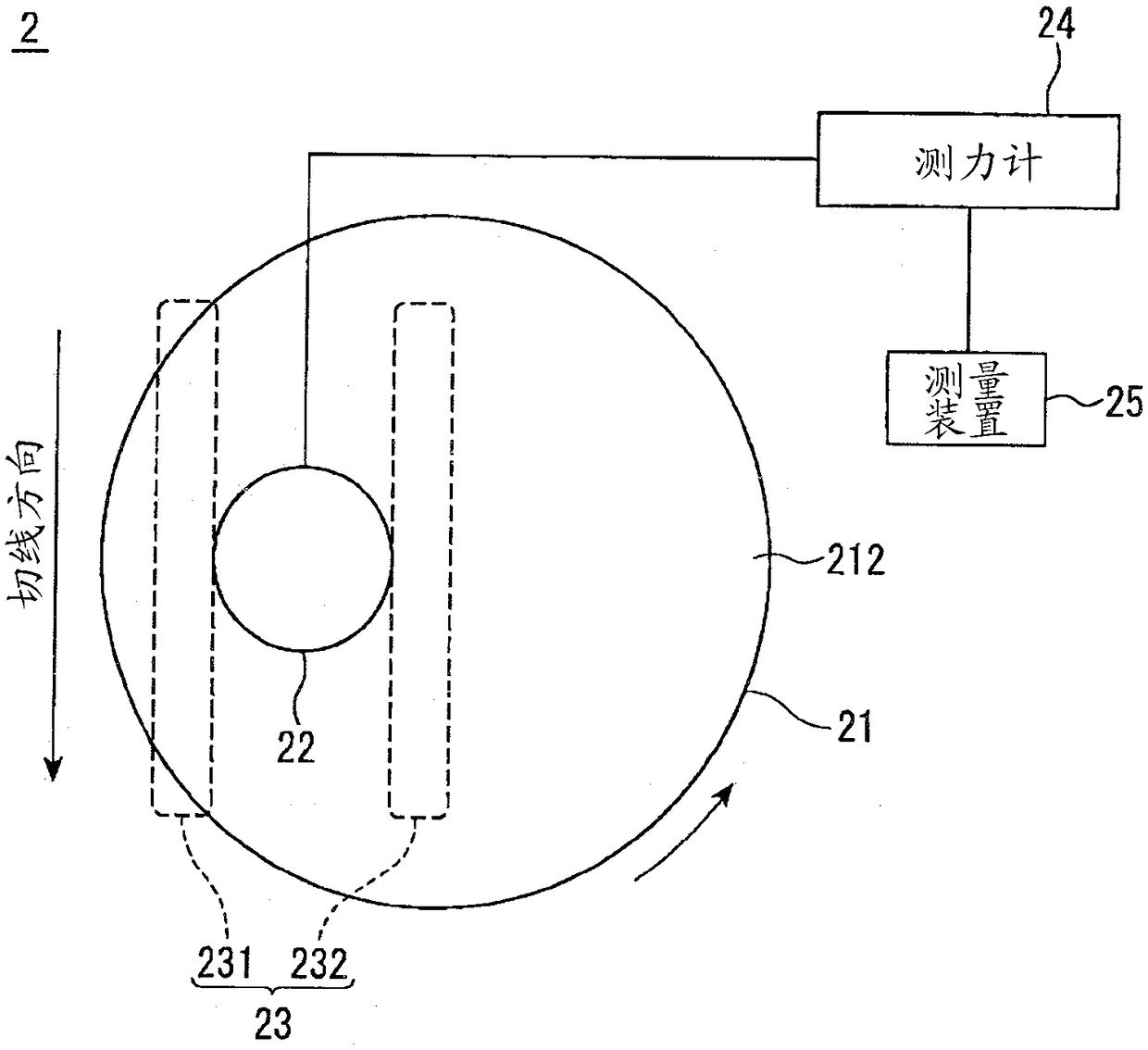

[0087] In the fine grinding process, use image 3 In the grinding device 1 shown, the grinding conditions (the rotation speed of the chassis, the rotation speed of the pressing head, the pressing pressure of the pressing head, etc.) are appropriately adjusted so that the dynamic friction force relative to the wafer is 0.017N / cm 2 . In this finish polishing step, a polishing solution (pH 10.15) in which colloidal silicon was dispersed in an aqueous base solution was used.

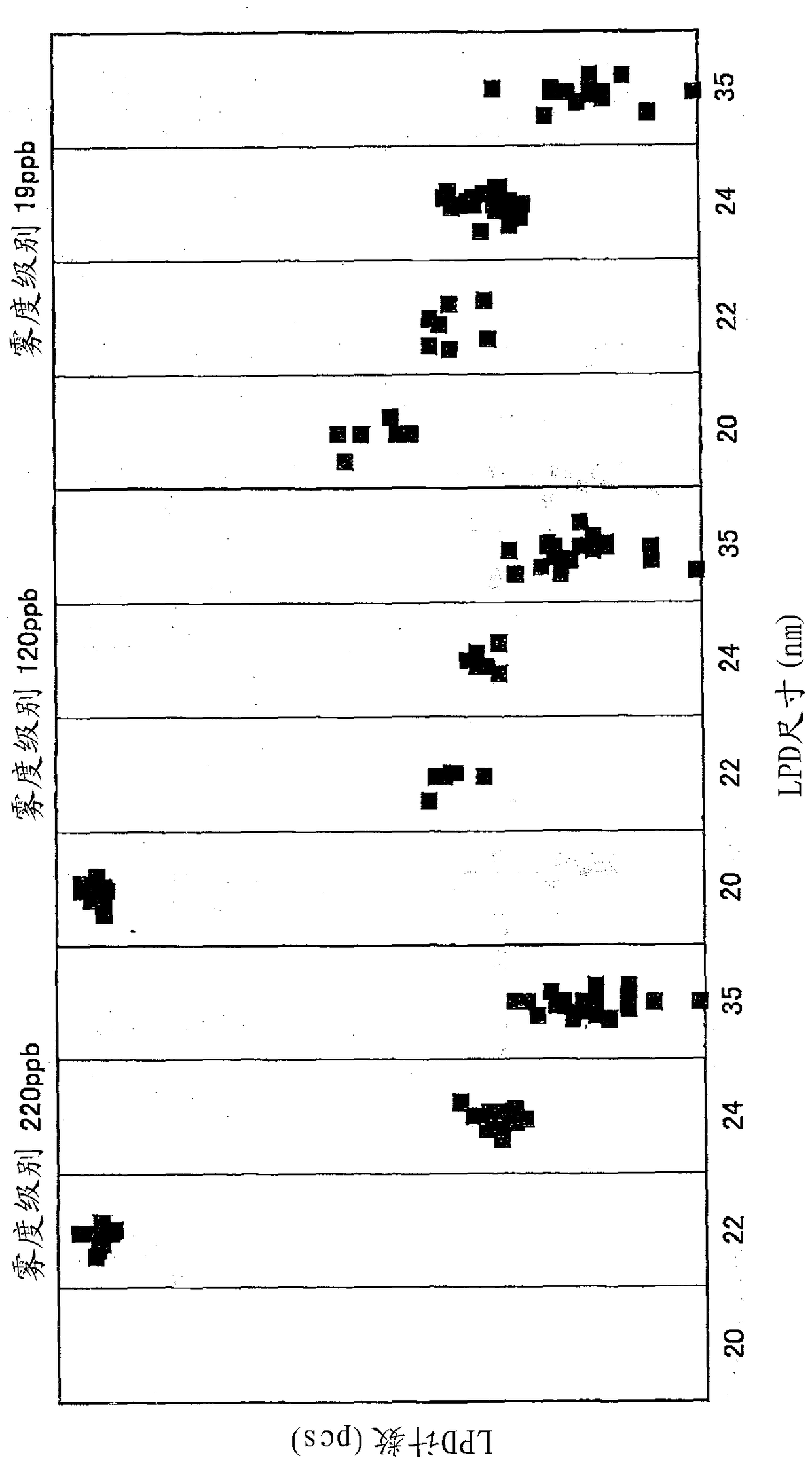

[0088] In the cleaning process, the front surface of the silicon wafer is cleaned by supplying a cleaning liquid at a predetermined flow rat...

Embodiment 2

[0099] A silicon wafer having a diameter of 300 mm having undergone the rough grinding process was prepared. With respect to the prepared silicon wafer, the conditions were changed as follows, and the finish polishing process was implemented, and then, the cleaning process was implemented with respect to the silicon wafer which completed the finish grinding process.

[0100] In the fine grinding process, use image 3 In the grinding device 1 shown, the grinding conditions (the rotation speed of the chassis, the rotation speed of the pressing head, the pressing pressure of the pressing head, etc.) are appropriately adjusted so that the dynamic friction force relative to the wafer is 0.017N / cm 2 . In this finish polishing step, a polishing liquid (pH 10.15) in which colloidal silicon was dispersed in an aqueous base solution was used.

[0101] In addition, adjust the grinding conditions appropriately, from 0.014N / cm 2 to 0.021N / cm 2 The dynamic frictional force against the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com