A method of soil preparation to improve soil production performance in greenhouses with sandy soil matrix

A greenhouse and production performance technology, applied in the direction of soil preparation methods, applications, agricultural machinery and tools, etc., can solve the problems of high transportation and labor costs, large engineering volume, and difficult sources of high-quality soil, so as to reduce the difficulty of greenhouse management and construction. Total cost reduction, beneficial effect of soil warming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 (control)

[0027] Control treatment (E17 shed): that is, the land preparation method routinely used in production. The specific operation is carried out according to the following steps:

[0028] On March 1, cucumbers began to grow seedlings;

[0029] On March 20th, foreign objects such as stones, straws, and stubble in the sandy soil of the cultivation bed were picked out, and the sandy soil of the cultivation bed was leveled;

[0030] On March 25th, evenly spread 4m of decomposed chicken manure on the pure sandy soil 1 3 , 17kg of diammonium phosphate, 7kg of urea and 10kg of potassium sulfate;

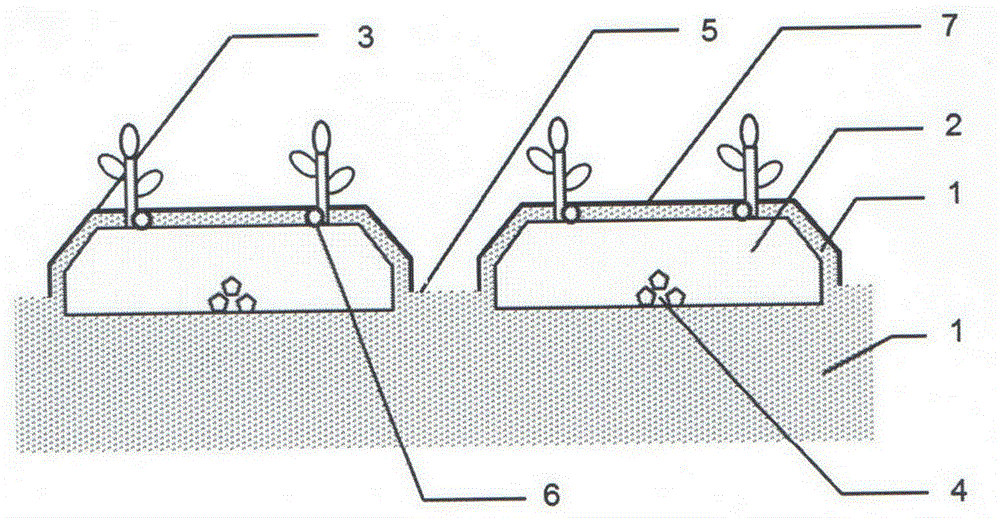

[0031] On March 26, the rotary tiller was used for 2 times of rotary tillage, and the organic fertilizer, base fertilizer and surface sand were fully mixed into nutrient soil 2;

[0032] On March 27, the position of the ridge was drawn according to the 1.2m ridge distance, and then part of the nutrient soil 2 of the ridge and furrow 5 was turned over on the ridg...

Embodiment 2

[0035] For the land preparation method processing (E19 shed) of the present invention, the concrete operation is carried out according to the following steps:

[0036] On March 1, cucumbers began to grow seedlings;

[0037] On March 20, the 8cm sandy soil on the surface of the cultivation bed was transported out of the greenhouse, and foreign objects such as stones, straws, and stubble in the sandy soil in the cultivation bed were picked out, and the sandy soil of the cultivation bed was leveled;

[0038] On March 25, 30m from the nearby farmland 3 The pastoral soil is evenly spread on the sand surface, and a pastoral soil layer is formed on the pure sandy soil 1, the thickness of the soil layer is about 8cm, and then 4m of decomposed chicken manure is spread on the pastoral soil. 3 ;

[0039] On March 26, the rotary tiller was used for 2 times of rotary tillage, and the pastoral soil, organic fertilizer and surface sand were fully mixed into nutritious soil 2;

[0040] On ...

Embodiment 3

[0046] For the land preparation method of the foreign soil method (E21 shed), the specific operation is carried out according to the following steps:

[0047] On March 1, cucumbers began to grow seedlings;

[0048] On March 20th, the 16cm sandy soil on the surface of the cultivation bed was transported out of the greenhouse, and foreign objects such as stones, straws, and stubble in the sandy soil in the cultivation bed were picked out, and the sandy soil of the cultivation bed was leveled;

[0049] On March 25, 60m from the nearby farmland 3 The pastoral soil was evenly spread on the sand surface, and a pastoral soil layer was formed on the pure sandy soil 1, the thickness of the soil layer was about 16cm, and then 4m of decomposed chicken manure was spread on the pastoral soil. 3 ;

[0050] On March 26, the rotary tiller was used for 2 times of rotary tillage, and the pastoral soil, surface sand, organic fertilizer and base fertilizer were fully mixed into nutrient soil 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com