Grain dryer

A grain dryer and drying tower technology, applied in the direction of preservation of seeds by drying, can solve the problems of low heat consumption per unit of drying speed, grain damage, grain over-drying, etc., and achieve the effect of ensuring thoroughness and uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

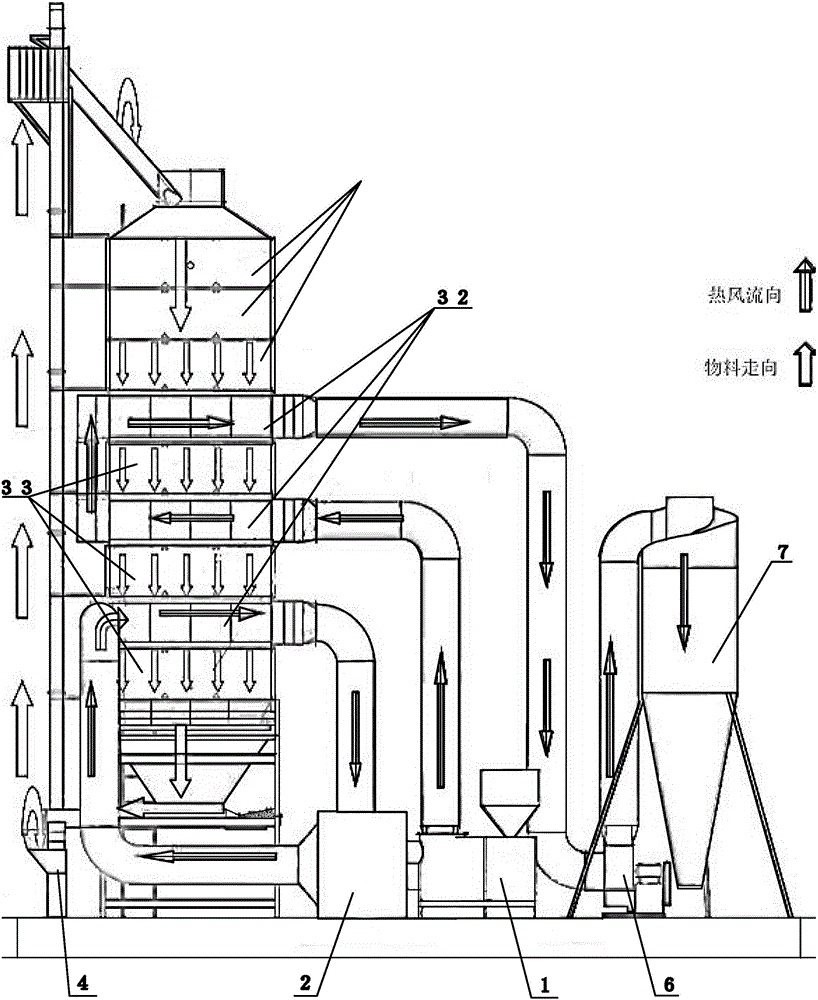

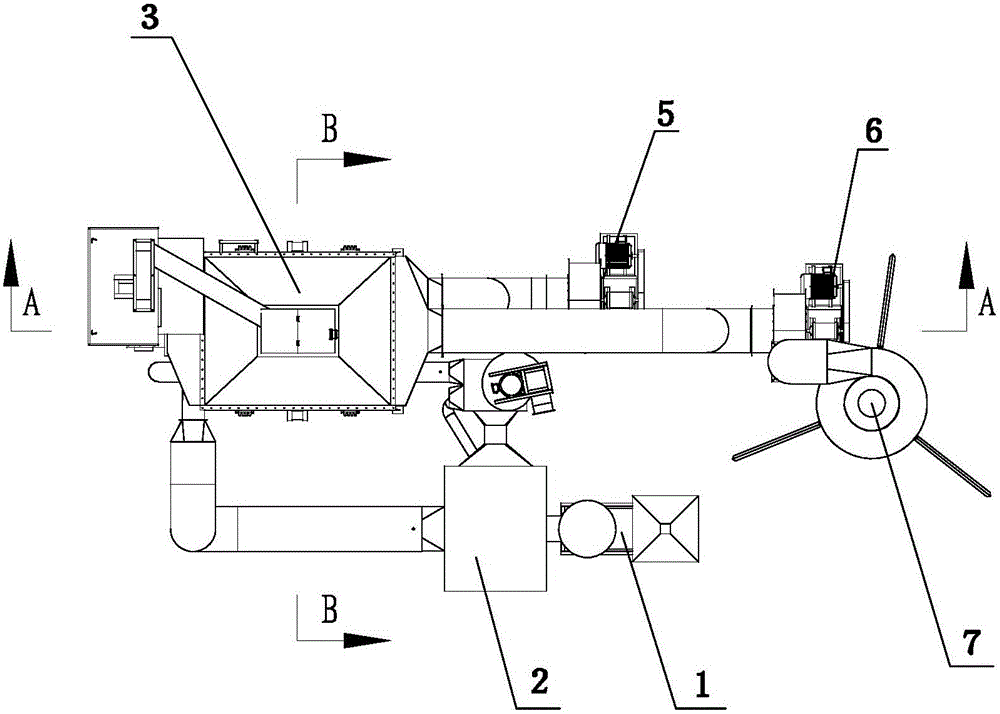

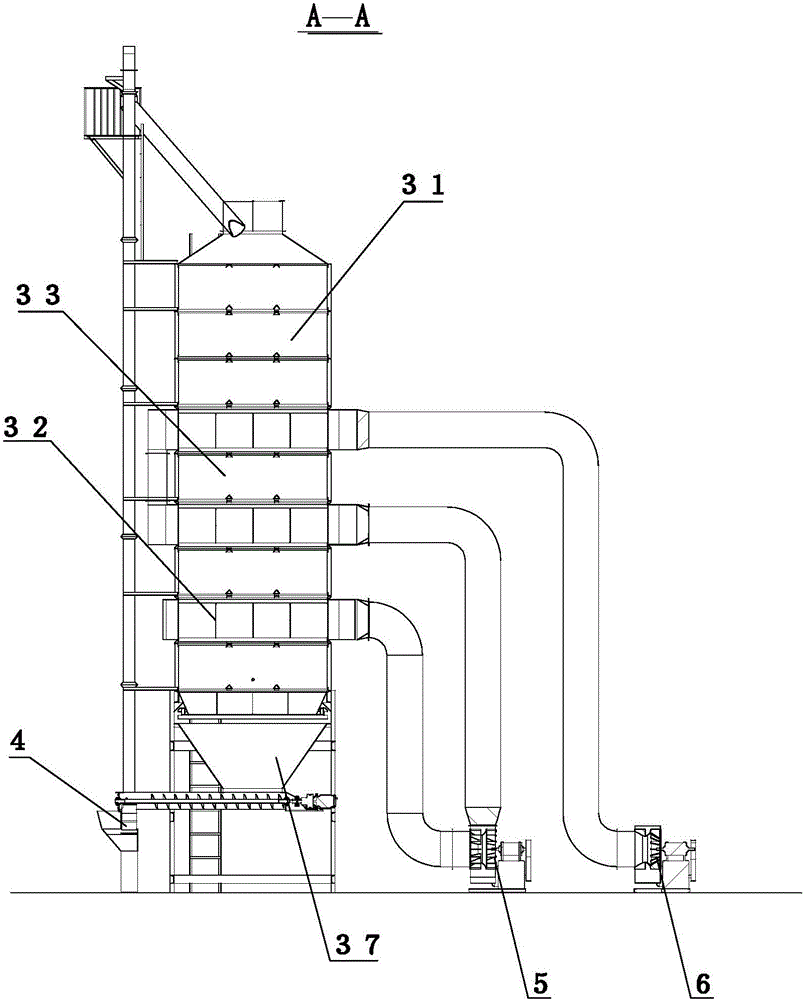

[0031] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

[0032] like Figure 1 to Figure 4 A kind of grain drier shown, comprises hot blast stove 1, heat exchanger 2, drying tower 3, bucket elevator 4, blower one 5, blower two 6, cyclone dust collector 7 and control cabinet.

[0033]In the cavity of the drying tower 3, the uppermost end is the feeding bin 31, and the lower part of the feeding bin 31 is a structure in which three-stage drying bins 32 and slowing bins 33 are arranged alternately, and the uppermost layer of drying bins 32 is connected with the feeding bin. The bins 31 are connected, and a blanking bin 34 is arranged below the slow-down bin 33 on the lowermost floor. The blanking bin 34 includes a plurality of conical or trapezoidal funnels arranged side by side, and a bottom plate 36 is respectively arranged c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com