Improved artificial hip joint femoral stem with rough film and preparation method thereof

A hip joint and femoral stem technology is applied in the field of improved artificial hip joint stems, which can solve the problems of easy loosening and fracture of the femoral stem, and achieve the effect of ensuring strength and mechanical properties, and being beneficial to bone attachment and bone ingrowth.

Inactive Publication Date: 2015-12-02

SHENZHEN YIHEPING

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide an improved artificial hip joint stem, which can customize the surface roughness most suitable for bone attachment and bone ingrowth for the femoral stem under the premise of ensuring mechanical properties and mechanical strength, and overcome the existing artificial hip joint Defects of easy loosening and possible fracture after femoral stem implantation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

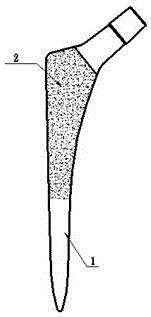

[0012] Such as figure 1 As shown, the present invention provides an artificial hip joint femoral stem, which is made by casting or forging. Then establish a rough thin layer model with the most suitable surface roughness (such as Ra=400) in the computer, and then melt the medical metal powder by laser or high-energy electron beam to obtain the required rough thin layer on the femoral stem of the artificial hip joint .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an improved artificial hip joint femoral stem which is characterized in that the improved artificial hip joint femoral stem is cast or forged, and then a rough medical metal film is formed on the corresponding surface, being in contact with a bone of a patient, of the femoral stem through additive manufacturing. The strength and mechanical properties of the femoral stem are guaranteed by casting and forging, and then the optimal roughness is customized for the rough film through the additive manufacturing, so that bone attachment or bone ingrowth can be facilitated to the maximum. The improved artificial hip joint femoral stem is suitable for a bone joint replacement surgery for human hip joint lesions.

Description

technical field [0001] The invention relates to an artificial joint in the field of medical bone joints, in particular to an improved artificial hip joint handle. Background technique [0002] The artificial hip joint stem is a human implant, which is used as a replacement for human femoral medullary cavity when the human hip joint disease requires orthopedic replacement surgery, so that the patient can restore the physiological function of the hip joint to a certain extent, relieve pain, and improve movement. and improve quality of life. [0003] In the prior art, the artificial hip joint femoral stem can be made by casting or forging, and then a rough thin layer is formed on the stem body (1) by sandblasting, or hydroxyapatite or titanium is thermally sprayed on the stem body (1 ) to form a rough thin layer; the femoral stem of the artificial hip joint and the rough surface thin layer can also be made integrally through additive manufacturing. However, the surface roughn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61F2/36A61L27/30A61L27/50

Inventor 不公告发明人

Owner SHENZHEN YIHEPING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com