Production method of aronia melanocarpa extract

A technology of Aronia nigra and a production method, which are applied in the field of production of Aronia nigra extract, can solve problems such as insufficient development and utilization of polyphenolic active substances, and achieve the effect of expanding development and utilization pathways.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

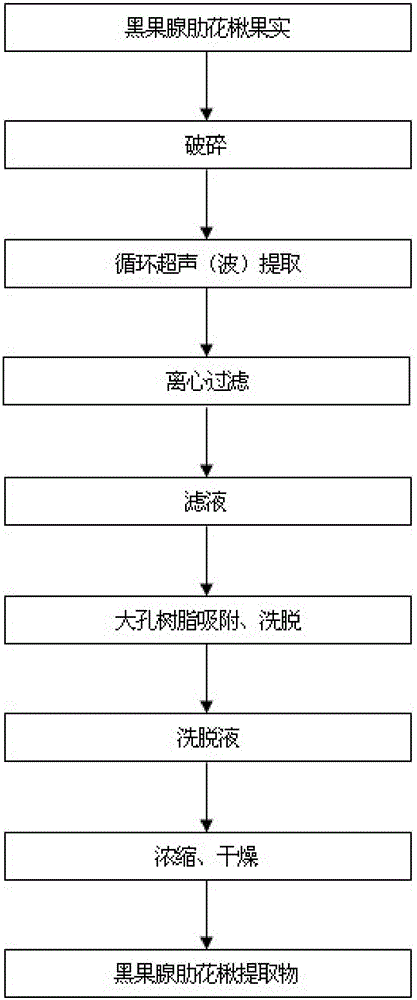

Method used

Image

Examples

Embodiment 1

[0029] 150kg dried fruit of Sorbus adenocarpa, crushed to 10 meshes, added 3000kg of 0.2% acetic acid aqueous solution, extracted with a circulating ultrasonic extraction machine for 60min, ultrasonic power 6500W, extraction temperature 40°C; after the extraction was completed, centrifuged to remove slag to obtain argonia 2635kg of Sorbus arborica extract; the extract is adsorbed by pretreated DM21 macroporous resin, washed with water to remove impurities, and eluted with 70% ethanol to obtain 325kg of peach red pigment refined solution, concentrated under reduced pressure to obtain 37kg of concentrated solution, and freeze-dried to obtain black Aronia fruit extract 8.45kg (containing flavonoids 37%, proanthocyanidins 21%, anthocyanins 36%).

Embodiment 2

[0031] 500kg of fresh fruit of Sorbus adenocarpa, after beating, add 600kg of pure aqueous solution, extract with a circular ultrasonic extractor for 30min, with ultrasonic power of 1500W, and extraction temperature of 50°C; add 400kg of pure water to the dregs and extract once again; combine the two extracts, Centrifugal filtration to remove slag to obtain 1375 kg of Sorbus nigra extract; the extract was absorbed by pretreated AB-8 macroporous resin, washed with water to remove impurities, and eluted with 60% methanol solution to obtain 178 kg of eluate, concentrated under reduced pressure to obtain concentrated Liquid 31kg, spray-dried to obtain 3.27kg (containing flavonoids 35%, proanthocyanidins 23%, anthocyanins 37%) of Aronia nigricarpa extract.

Embodiment 3

[0033] 10kg dried fruit of Sorbus adenocarpus, crushed to 20 mesh, add 120L of 10% ethanol solution, extract for 45min with a circular ultrasonic extractor, ultrasonic power 1500W, extraction temperature 30°C; add 100L of 10% ethanol solution to the dregs and extract once more Merge the 2 extracts, centrifuge and filter to remove slag to obtain 195L of Sorbus black fruit extract; the extract is absorbed by pretreated D101 macroporous resin, washed with water to remove impurities and eluted with 50% acetone solution to obtain 28L of eluate, Concentrate under reduced pressure to obtain 2.7 kg of concentrated solution, and vacuum-dry to obtain 485 g of Aronia nigra extract (containing 39% flavonoids, 21% proanthocyanidins, and 28% anthocyanins).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com