Biological denitrification process of organic nitrogen waste water

A technology for biological denitrification and organic wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve waste liquid treatment difficulties, low treatment efficiency, physical denitrification Phosphorus removal technology does not have obvious removal effect, etc., to achieve the effect of short-range nitrification and denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

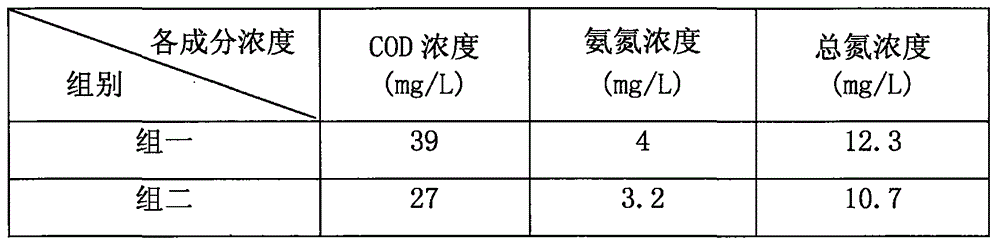

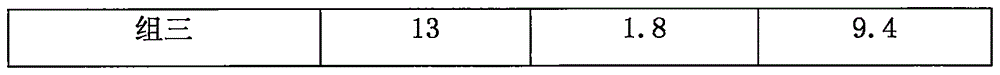

Embodiment 1

[0025] A biological denitrification process for organic wastewater, comprising the following steps:

[0026] (1) Solid-liquid separation is used for solid-liquid separation of organic wastewater to remove suspended solids, adjust the flow of wastewater, and control the wastewater to be sent into the anaerobic fluidized bed at a speed of 1.45m / s;

[0027] (2) Heterotrophic bacteria are coated on the anaerobic fluidized bed, and the wastewater flows through the anaerobic fluidized bed. The heterotrophic bacteria ammoniate pollutants such as protein and fat and release ammonia, and convert organic nitrogen into ammonia nitrogen. Then enter the separation membrane reaction bath, the mixed solution is filtered by the membrane under the suction of the outlet pump to form treated water, and the remaining organic matter is collected by the membrane to remove particulate pollutants in the sewage. The operation mode of the outlet pump is intermittent. Open for 6 minutes, stop for 6 minu...

Embodiment 2

[0031] A biological denitrification process for organic wastewater, comprising the following steps:

[0032] (1) Solid-liquid separation is used for solid-liquid separation of organic wastewater to remove suspended solids, adjust the flow rate of wastewater, and control the wastewater to be sent into the anaerobic fluidized bed at a speed of 1.55m / s;

[0033] (2) Heterotrophic bacteria are coated on the anaerobic fluidized bed, and the wastewater flows through the anaerobic fluidized bed. The heterotrophic bacteria ammoniate pollutants such as protein and fat and release ammonia, and convert organic nitrogen into ammonia nitrogen. Then enter the separation membrane reaction bath, the mixed solution is filtered by the membrane under the suction of the outlet pump to form treated water, and the remaining organic matter is collected by the membrane to remove particulate pollutants in the sewage. The operation mode of the outlet pump is intermittent. Open for 8 minutes and stop fo...

Embodiment 3

[0037] A biological denitrification process for organic wastewater, comprising the following steps:

[0038] (1) Solid-liquid separation is used for solid-liquid separation of organic waste water to remove suspended solids, adjust the waste water flow rate, and control the waste water to be sent into the anaerobic fluidized bed at a speed of 1.65m / s;

[0039] (2) Heterotrophic bacteria are coated on the anaerobic fluidized bed, and the wastewater flows through the anaerobic fluidized bed. The heterotrophic bacteria ammoniate pollutants such as protein and fat and release ammonia, and convert organic nitrogen into ammonia nitrogen. Then enter the separation membrane reaction bath, the mixed solution is filtered by the membrane under the suction of the outlet pump to form treated water, and the remaining organic matter is collected by the membrane to remove particulate pollutants in the sewage. The operation mode of the outlet pump is intermittent. Open for 10 minutes, stop for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com