Reversible covalent crosslinking polysiloxane elastomer, preparation method therefor and application thereof

A polysiloxane and covalent cross-linking technology is applied in the field of reversible covalent cross-linking polysiloxane and its preparation, which can solve the problems of poor mechanical properties and high reprocessing temperature, and achieves low cost, excellent mechanical properties, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of Reversible Covalently Crosslinked Polysiloxane Elastomer

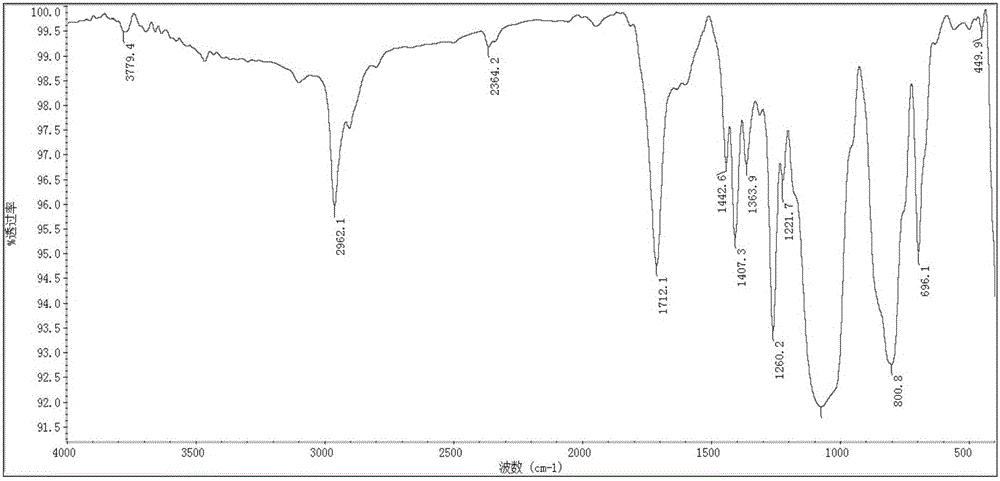

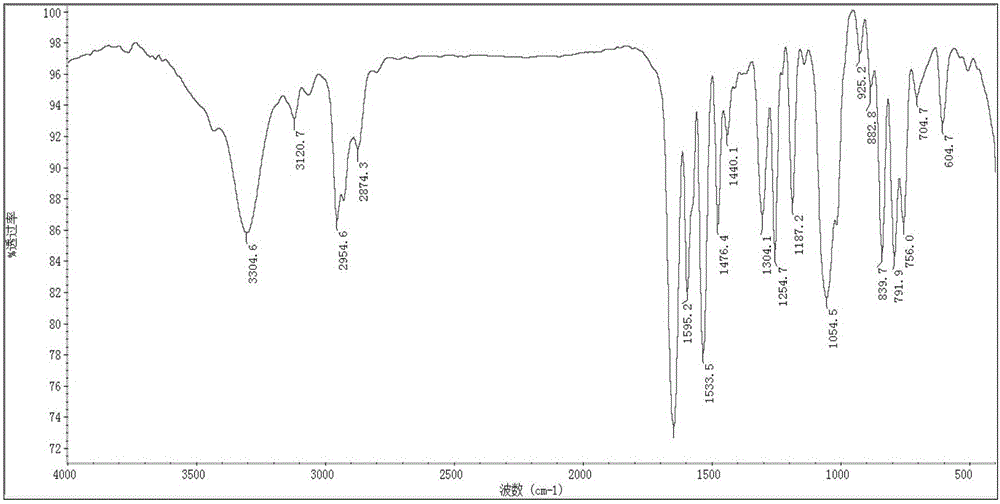

[0030] (1) Synthesis of polysiloxane with dienophiles in side groups: aminopropylmethylsiloxane-dimethylsiloxane copolymer (brand: AMS-191, aminopropylmethylsiloxane content 9~11%, average molecular weight 3000) 10g, maleic anhydride 6.52g and 100ml glacial acetic acid add in the 250ml single-necked flask that has condenser tube, heat to 140 ℃ of stirring reaction in oil bath pan for 12 hours. After the reaction is completed, rotate at a temperature of 60°C and a vacuum of 0.08 to 0.1 MPa to remove glacial acetic acid to obtain a light brown viscous liquid, then dissolve the light brown viscous liquid in 100ml of dichloromethane and wash with deionized water Three times, the organic layer was collected, dried over anhydrous magnesium sulfate, and the dichloromethane was removed by rotary evaporation to obtain the polysiloxane with maleimide in the side group. figure 1 It can be seen th...

Embodiment 2

[0033] Example 2: Reprocessability of Polysiloxane Elastomers with Reversible Covalent Crosslinks

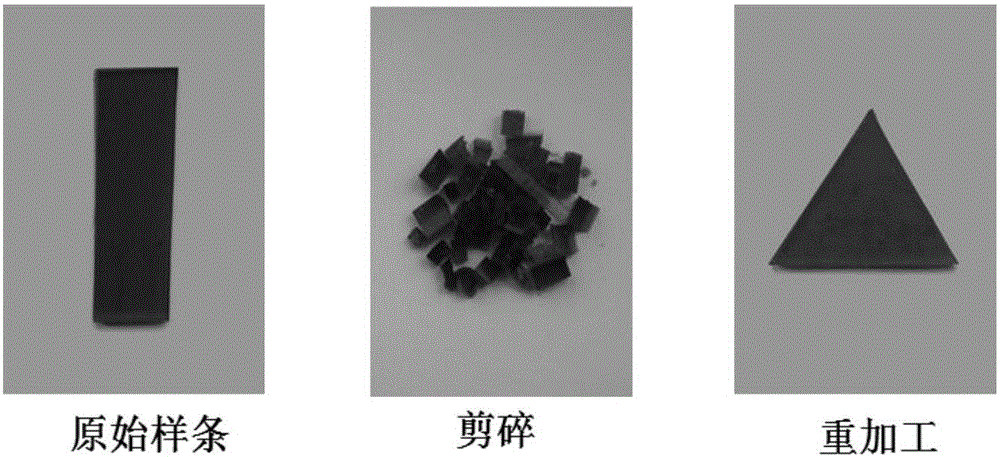

[0034] Cut the prepared polysiloxane elastomer rectangular splines containing reversible covalent crosslinking points into small pieces, and then cut them into small pieces for molding. Place at ℃ for 24h, such as image 3 shown.

[0035] Depend on image 3 It can be seen that without any external repair agent or catalyst, a complete sheet with a smooth surface can be obtained under mild conditions, with good elasticity and self-repair. Example 3: Self-healing properties of polysiloxane elastomers with reversible covalent crosslinks

Embodiment 3

[0035] Depend on image 3 It can be seen that without any external repair agent or catalyst, a complete sheet with a smooth surface can be obtained under mild conditions, with good elasticity and self-repair. Example 3: Self-healing properties of polysiloxane elastomers with reversible covalent crosslinks

[0036] Cut off the prepared rectangular polysiloxane elastomer strips containing reversible covalent crosslinking points with a blade, then quickly fit the two ends together and place them in an oven at 140°C for 3 hours, and then place them in an oven at 80°C for 3 hours, as Figure 4 shown.

[0037] Depend on Figure 4 It can be seen that when the prepared cross-linked polysiloxane elastomer is heated to 120-140 °C, the reversible covalent cross-linking points will break, and when the temperature drops to 60-100 °C, the reversible covalent cross-linking points can be re-established. Formed to realize the reversibility of the cross-linked network structure of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com