Preparation method of diamond/aluminum composite material

An aluminum composite material and diamond technology, which is applied in the field of diamond/aluminum composite material preparation, can solve problems such as the difficulty of sintering and densification of composite heat dissipation materials, the difficulty of realizing industrial production, and the complexity of molding processes, so as to improve interface reaction kinetics, The effect of preventing high temperature oxidation corrosion and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

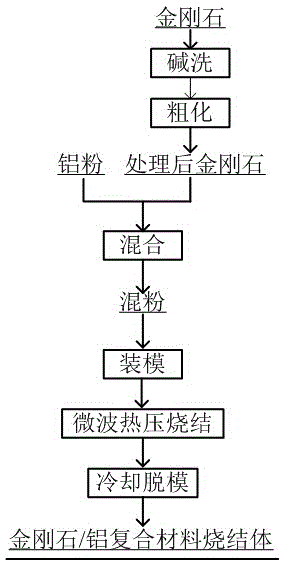

[0024] like figure 1 Shown, the preparation method of this diamond / aluminum composite material, its specific steps are as follows:

[0025] (1) First, 5g of diamond particles with a particle size of 80μm are washed with alkali (60ml of NaOH solution with a concentration of 10wt.% is used to boil for 30min, and rinsed with distilled water for 2 to 3 times to remove grease and other dirt on the diamond surface. Stir with a magnetic stirrer during the oiling process), roughen (use 60ml of nitric acid solution with a concentration of 30wt.% to boil for 30min, wash with distilled water 2 to 3 times to roughen the surface, increase the contact area with the substrate, and roughen the surface. During the process, a magnetic stirrer is used for stirring), and then aluminum powder (particle size is 30 μm, purity greater than 99.9%) is added according to the volume ratio of 50:50 and mixed evenly to obtain a mixed powder;

[0026] (2) Put the mixed powder obtained in step (1) into a gr...

Embodiment 2

[0028] like figure 1 Shown, the preparation method of this diamond / aluminum composite material, its specific steps are as follows:

[0029] (1) First, 5g of diamond particles with a particle size of 150μm are washed with alkali (use 60ml of NaOH solution with a concentration of 10wt.% to boil for 30 minutes, rinse with distilled water for 2 to 3 times, and remove the grease and other dirt on the diamond surface. Stir with a magnetic stirrer during the oiling process), roughen (use 60ml of nitric acid solution with a concentration of 30wt.% to boil for 30min, wash with distilled water 2 to 3 times to roughen the surface, increase the contact area with the substrate, and roughen the surface. During the process, a magnetic stirrer is used for stirring), and then aluminum powder (particle size is 80 μm, purity greater than 99.9%) is added according to the volume ratio of 70:30 and mixed evenly to obtain a mixed powder;

[0030] (2) Put the mixed powder obtained in step (1) into a...

Embodiment 3

[0032] like figure 1 Shown, the preparation method of this diamond / aluminum composite material, its specific steps are as follows:

[0033] (1) First, 5g of diamond particles with a particle size of 100μm are washed with alkali (use 60ml of NaOH solution with a concentration of 10wt.% to boil for 30min, and rinse with distilled water for 2 to 3 times to remove grease and other dirt on the surface of the diamond. Stir with a magnetic stirrer during the oiling process), roughen (use 60ml of nitric acid solution with a concentration of 30wt.% to boil for 30min, wash with distilled water 2 to 3 times to roughen the surface, increase the contact area with the substrate, and roughen the surface. During the process, a magnetic stirrer is used for stirring), and then aluminum powder (particle size is 100 μm, purity greater than 99.9%) is added according to the volume ratio of 65:35 and mixed evenly to obtain a mixed powder;

[0034](2) Put the mixed powder obtained in step (1) into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com