Method of preparing nickel gallium alloy by ionic liquid electrodeposition

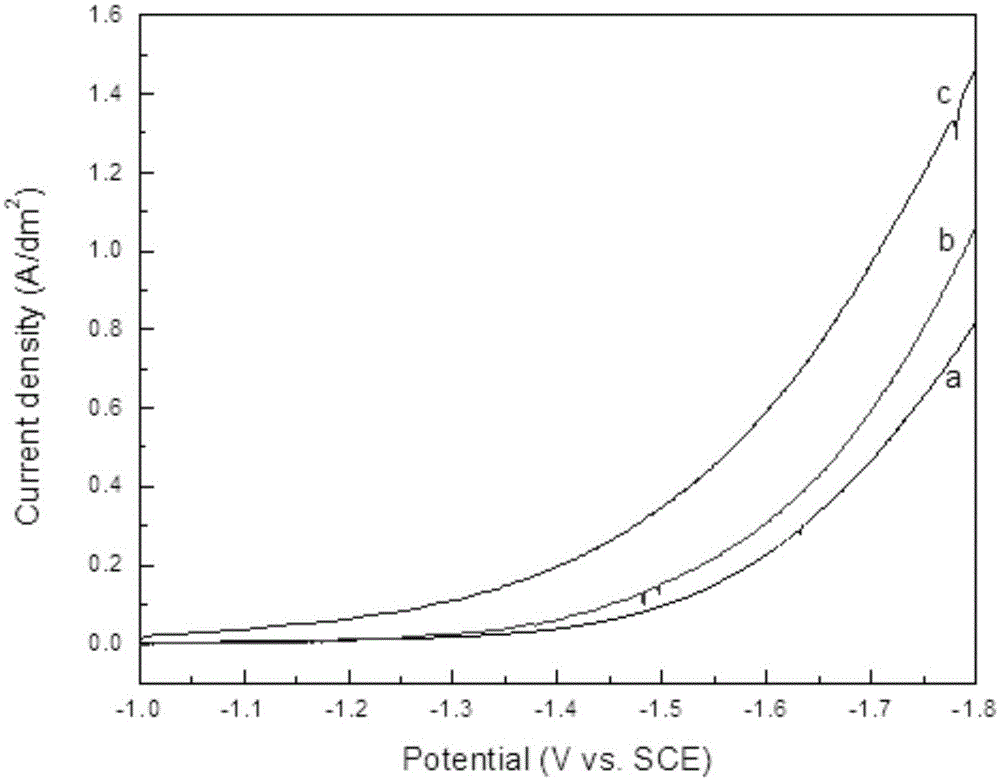

A technology of ionic liquid and ionic liquid solvent, which is applied in the field of preparation of nickel-gallium alloy, can solve the problems of complex preparation method, high temperature of nickel-gallium alloy, unfavorable electrocatalysis of nickel-gallium alloy catalyst, etc., and achieve simple preparation method and high catalytic activity , The effect of large catalytic reaction current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: the method for preparing nickel-gallium alloy by ionic liquid electrodeposition in this embodiment is carried out according to the following steps:

[0026] 1. Preparation of ionic liquid plating solution

[0027] First, the ionic liquid solvent is dehydrated and dried, then the vacuum-dried nickel salt and gallium salt are added to the ionic liquid solvent, and then the solubilizer and grain refiner are added in sequence, and heated and stirred until the nickel salt and gallium salt are completely dissolved , to obtain the electroplating solution;

[0028] The concentration of the nickel salt in the electroplating solution is 0.1g / L~30g / L; the concentration of the gallium salt in the described electroplating solution is 0.1g / L~30g / L; the concentration of the solubilizer in the described electroplating solution is 10ml / L~500ml / L; the concentration of the grain refiner in the electroplating solution is 0.1g / L~10g / L;

[0029] Second, the pretrea...

specific Embodiment approach 2

[0035] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the specific method of dehydrating and drying the ionic liquid solvent is as follows: the ionic liquid is placed in an open glass container and placed in a vacuum drying oven. Dry at 80°C for 24h. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the heating temperature in step 1 is 50-90°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

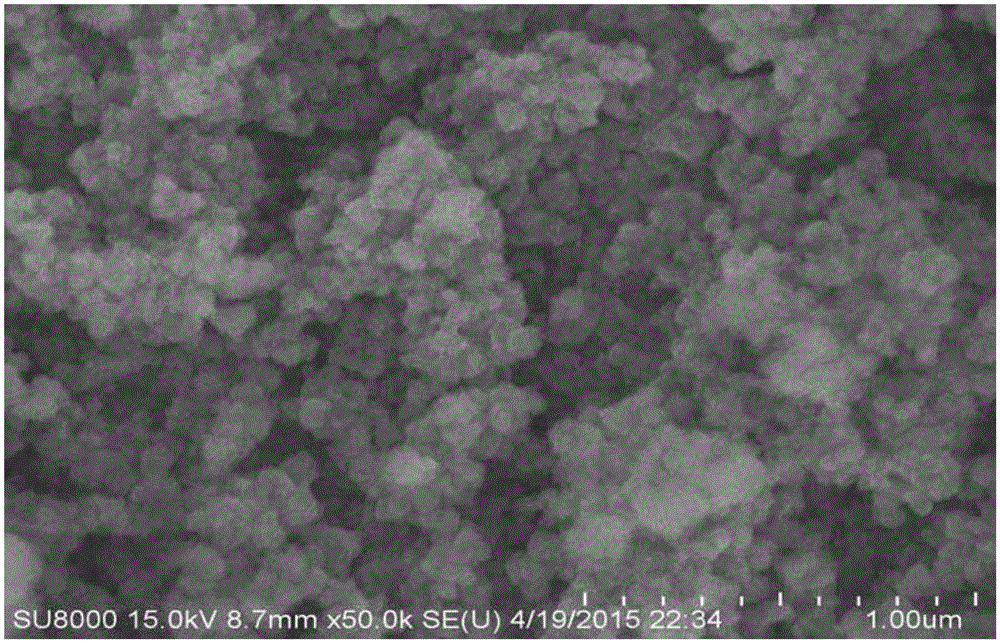

| Particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com