Method for manufacturing soldering circuit board, soldering circuit board, and method for mounting electronic component

A technology of solder circuit substrate and manufacturing method, applied in the direction of printed circuit manufacturing, circuit, printed circuit, etc., to achieve the effect of expanding the range of choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

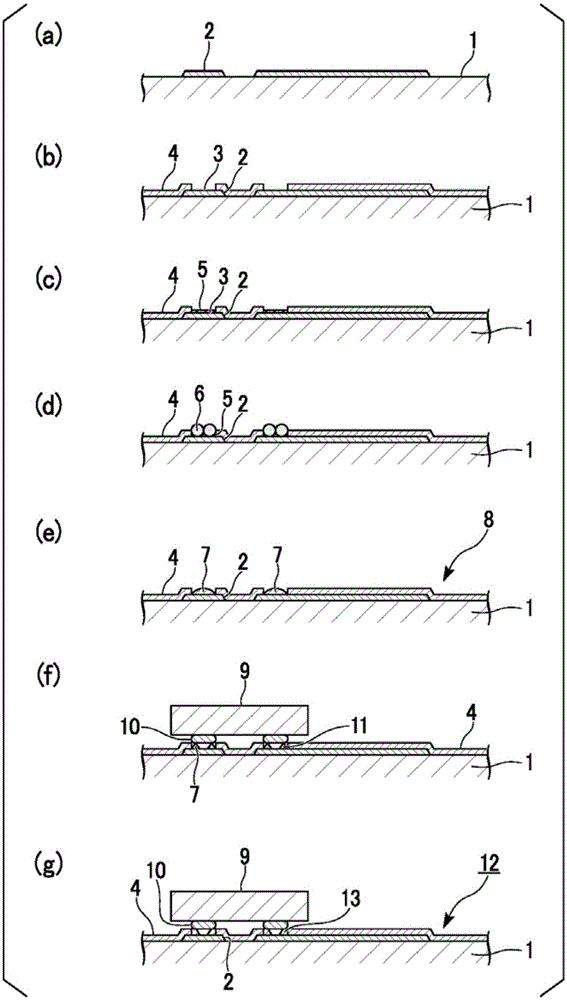

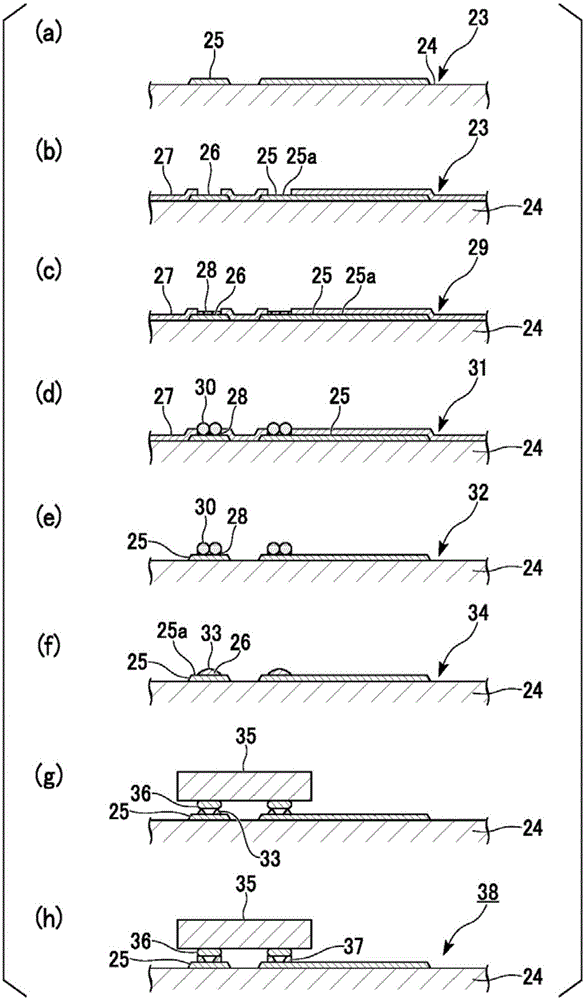

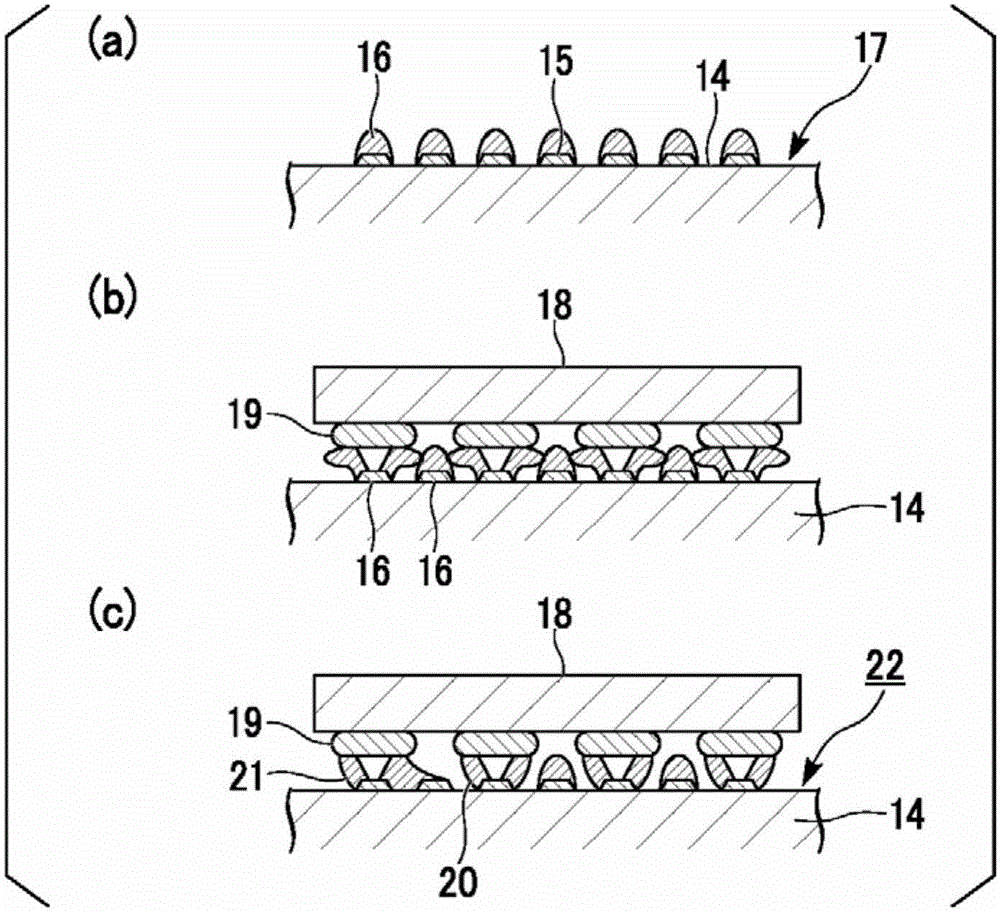

Method used

Image

Examples

Embodiment 1

[0105] Copper was used as a conductive substance to produce a printed wiring board (hereinafter simply referred to as "printed wiring board"). The line width of the circuit pattern of the printed wiring board made of the conductive material was 25 μm, and the space between the narrowest circuit patterns was 25 μm. A substrate in which a photoresist (model: H-7034, manufactured by Hitachi Chemical Co., Ltd.) was attached to the printed wiring board was prepared. After exposing the printed wiring board to ultraviolet rays using a photomask, the printed wiring board is patterned using an alkaline developing solution such as a 1% sodium carbonate aqueous solution. In the region not covered with the resist on the surface of the conductive circuit electrode, the size was set to 25×80 μm every other electrode.

[0106] As the tackiness-imparting compound solution, the alkyl group of R12 of the general formula (3) was changed to C by using acetic acid. 11 h 23 , a solution in which...

Embodiment 2

[0110] A bare chip was mounted on a printed wiring board in the same steps and conditions as in Example 1, except that the heating of the printed wiring board after solder powder adhesion was not performed (second heating step).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com