Hollow fiber forward osmosis membrane and preparing method thereof

A forward osmosis membrane and forward osmosis technology, applied in the field of hollow fiber forward osmosis membrane and preparation, can solve the problems of low filling rate of membrane modules, small specific surface area, difficult membrane cleaning, etc., and achieve easy cleaning, large effective membrane area, and easy preparation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing a hollow fiber forward osmosis membrane, which includes the following steps: S1: immerse the support tube in a water-phase monomer solution at 20-50 degrees Celsius for 2-480 seconds, and blot the surface layer after taking it out liquid; S2: Then immerse in the organic phase monomer solution at 20-50 degrees Celsius for 2-300 seconds, take it out and blot the liquid on the outer surface; then perform heat treatment in an environment of 50-120 degrees Celsius for 1-30 minutes; S3: treat all The heat-treated support tube is rinsed with deionized water for 20 to 40 seconds to obtain a hollow fiber forward osmosis membrane in the inner support tube; the hollow fiber forward osmosis membrane prepared by this preparation method has a high filling rate, is anti-pollution and is easy to clean. The effective area is large and the permeability is high; at the same time, the preparation method of the hollow fiber forward o...

Embodiment 1

[0030] The first step is to configure the aqueous phase and organic phase solution: take 10g of m-phenylenediamine and 2g of sodium hydroxide and dissolve it in a 150g water tank to configure the aqueous phase solution, and dissolve 10g of isophthaloyl chloride in 190g of n-octane to configure the organic phase solution;

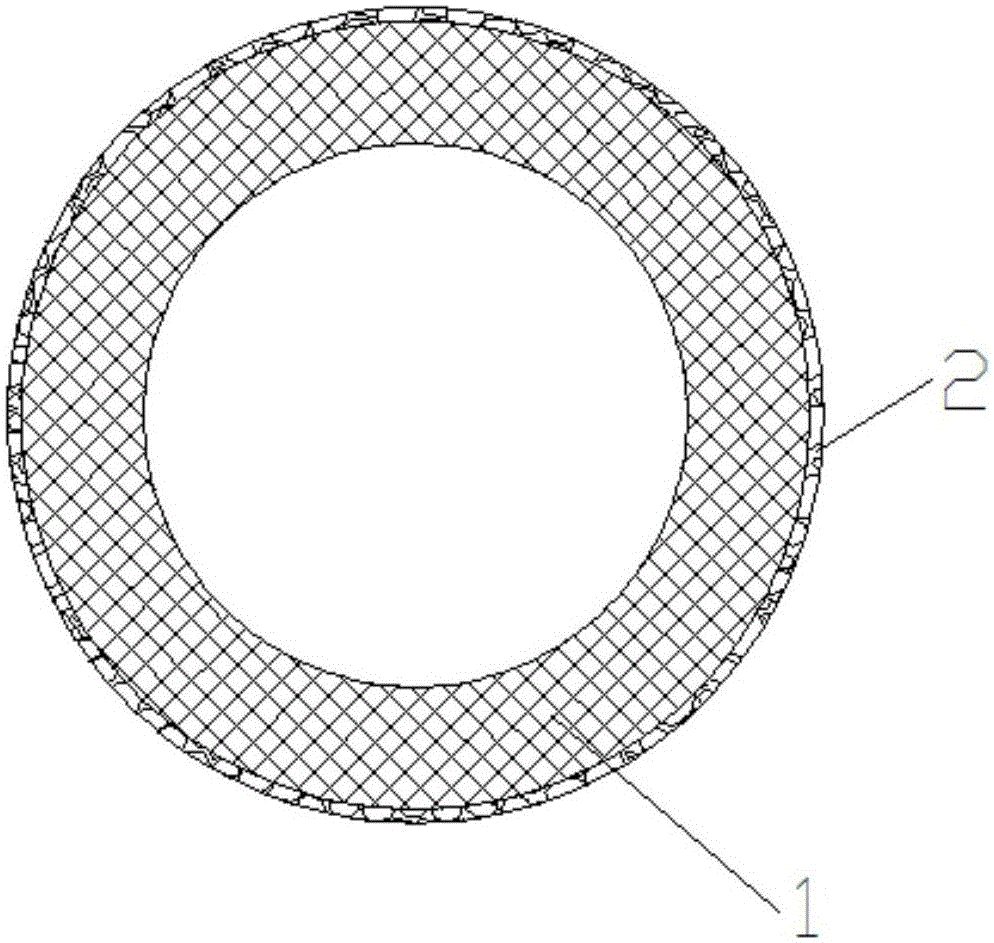

[0031] The second step is to carry out interfacial reaction on the outer surface of the support tube 1 to prepare the nanofiltration separation layer 2: put the support tube into the aqueous phase solution at 25°C for 60 seconds, and then purge the surface of the support tube to remove the excess water phase on the surface solution, and then immersed in the organic phase solution at 25°C for 60 seconds, taken out and entered into the heat treatment channel at 100°C for 1 minute, and then rinsed with deionized water for 30 seconds to prepare the inner support tube hollow fiber forward osmosis membrane, wherein the support tube 1 and forward osmosis membrane 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com