Sliding track type diamond section insulator

A segmented insulator and slideway-type technology, applied in the direction of overhead lines, etc., can solve the problems of short service life, arc resistance, and wear resistance, etc., and achieve the effect of good bearing tension, avoiding collision, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

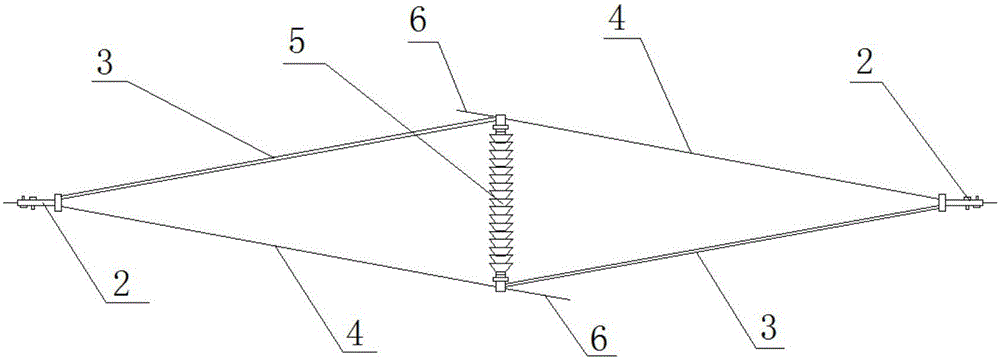

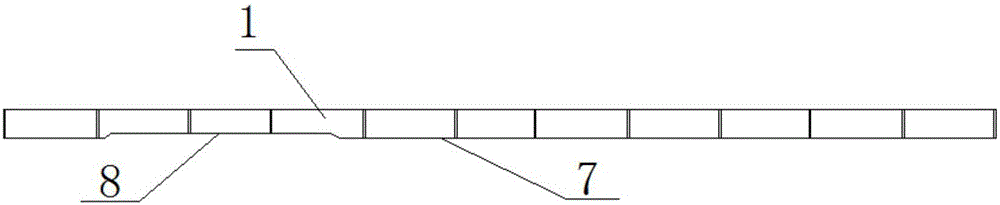

[0049] Such as figure 2 As shown, the slideway-type rhombic segmental insulator has a structure including joint clamp 2, bridge insulator 5, metal slideway 4 and insulating slideway 3, wherein the metal slideway 4 and the insulating slideway 3 are two and connected to each other. Intervals form a rhombus structure, and the longitudinal two ends of the rhombus structure are respectively connected to the connector clamp 2, which is an important part of the contact sliding surface 7 that is in contact with the locomotive pantograph and allows it to slide over. The section insulator is connected with the contact wire on the driving line, and assumes the role of electrical section on the electrified railway, urban light rail and subway contact network.

[0050] The transverse ends of the rhombus structure are respectively connected to the bridge insulators 5, and the insulating slide 3 adopts the insulating rod of the catenary segmenter, and the structure of the insulating rod of ...

Embodiment 2

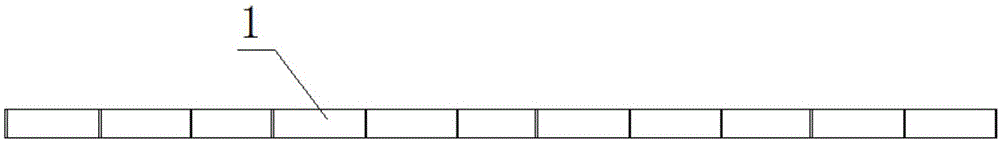

[0054] Such as figure 1 As shown, on the basis of Embodiment 1, the ceramic composite material part 1 in this embodiment is a plurality of sequentially connected cylindrical structural components.

[0055] This structure further increases the bearing pressure of the insulating rod of the catenary sectionalizer, improves the elasticity of the catenary, effectively improves the use effect of the product, and greatly prolongs the service life of the product.

Embodiment 3

[0057] On the basis of Example 2, the outer structure of the composite insulating rod described in this example: the inside is a mandrel made of chemical fiber bundles, and the outer surface is an insulating protective layer.

[0058] Among them, the inner core rod can be made of epoxy glass fiber reinforced plastic core rod, which has a large allowable stress, can meet the use requirements in terms of bearing contact line tension, bending deflection, etc., and has a large safety margin. The insulating protective layer is made of silicone rubber umbrella cover, which is resistant to pollution flashover voltage and is not easy to be damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com