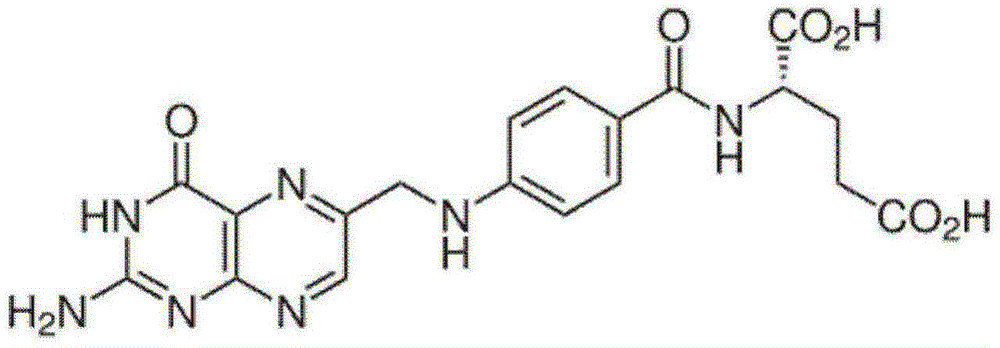

Method for preparing nitrogen-doped porous carbon material on the basis of folic acid

A technology of porous carbon and nitrogen doping, which is applied in the field of supercapacitor electrode carbon materials, can solve the problems of not being green and environmentally friendly, and achieve the effects of low requirements for reaction conditions, short reaction cycle, and uniform distribution of pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

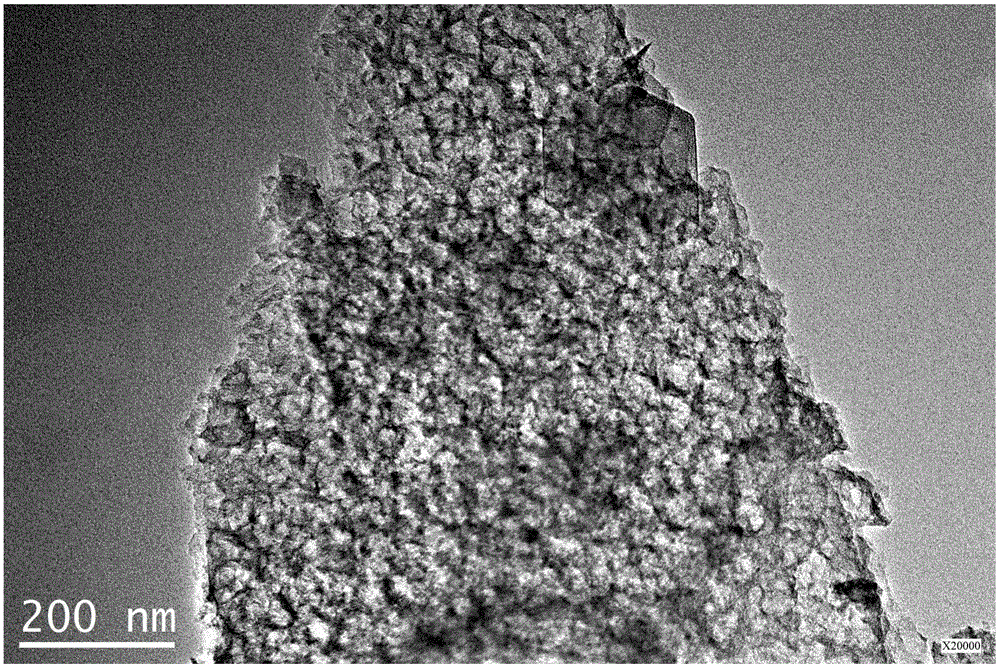

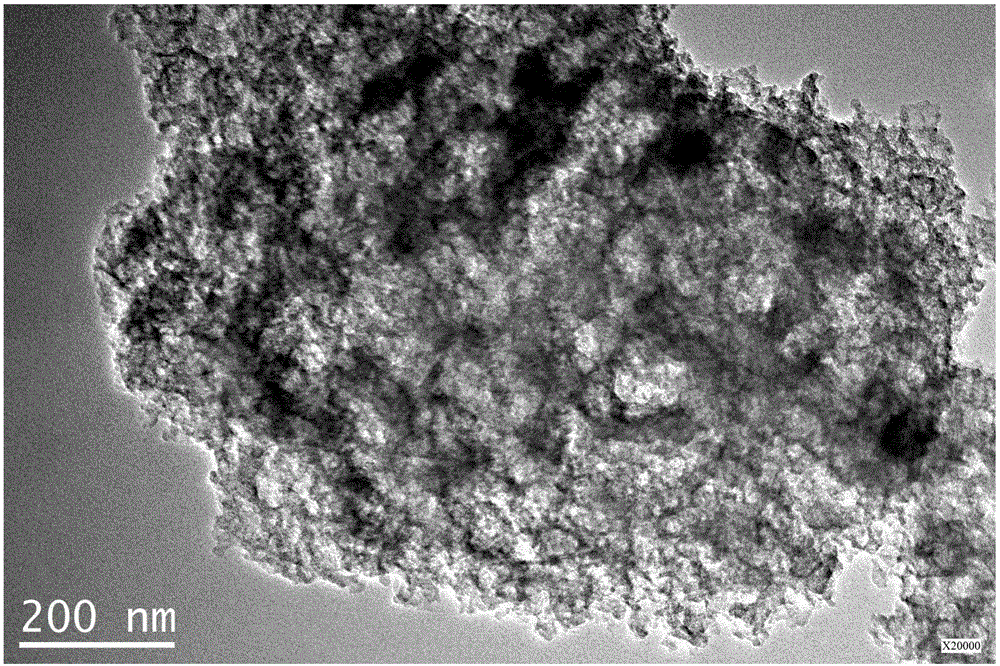

[0025] Weigh folic acid and zinc acetate according to a mass ratio of 3:1 and grind them thoroughly, then move them to a porcelain boat in a horizontal tube furnace, and feed argon for 30 minutes, then heat the horizontal tube furnace at a heating rate of 5°C / min to 1000° C., and kept for 4 hours in an argon atmosphere; the obtained product was washed with deionized water and then vacuum-dried at 120° C. for 12 hours to obtain a nitrogen-doped porous carbon material.

Embodiment 2

[0027] Weigh folic acid and zinc acetate according to the mass ratio of 1:2 and grind them thoroughly, then move them to a porcelain boat in a horizontal tube furnace, pass through argon for 30 minutes, and then heat the horizontal tube furnace at a heating rate of 10°C / min to 1200° C., and kept in an argon atmosphere for 2 hours; the obtained product was washed with deionized water and then vacuum-dried at 120° C. for 12 hours to obtain a nitrogen-doped porous carbon material.

Embodiment 3

[0029] Weigh folic acid and zinc acetate according to the mass ratio of 1:5 and grind them thoroughly, then move them to a porcelain boat in a horizontal tube furnace, pass through argon for 30 minutes, and then heat the horizontal tube furnace at a heating rate of 15°C / min to 950° C., and kept for 10 h in an argon atmosphere; the obtained product was washed with deionized water and then vacuum-dried at 120° C. for 12 hours to obtain a nitrogen-doped porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com